Why You Should Seriously Consider 3D Manufacturing Simulation (Videos included)

3D manufacturing simulation is something you cannot go without these days if you want to be a serious contender in the manufacturing industry. As the digital embodiment of your factory floor or manufacturing processes, 3D manufacturing simulation can give you a birds-eye view of your entire manufacturing process without ever having to leave the comfort of your office.

- Why Visual Components?

- Business Benefits of 3D Manufacturing Simulation

- How Has the Manufacturing Industry Changed in Recent Years?

- How Can You Avoid Costly Mistakes?

- How Can System Integrators Benefit from 3D Manufacturing Simulation?

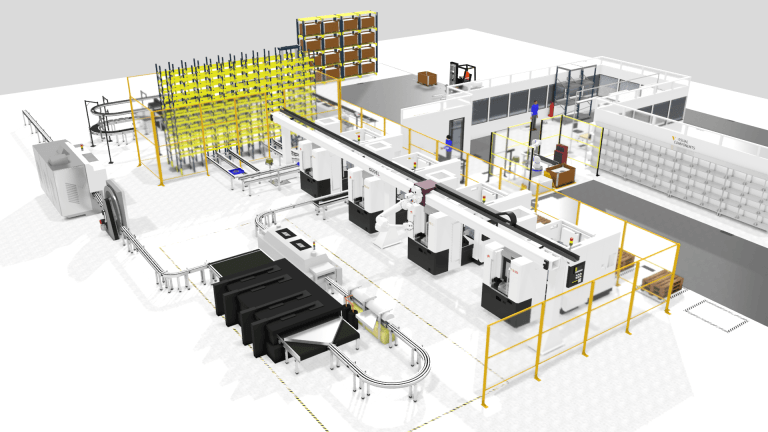

Removing the guesswork and avoiding costly mistakes are just a few examples as to why 3D simulation has become an incredible driving force in the manufacturing industry in the recent decades. Manufacturers use 3D simulation to optimize every aspect of the production system lifecycle, from conceptual design to checking capacity, determining lead times, modeling “what-if” scenarios, and comparing alternative machine layouts and workflows.

This blog post will cover why you should seriously consider Visual Components if you want to enhance your manufacturing capabilities. Continue on as Graham Wloch, Head of Business Development at Visual Components, takes you through everything you need to know about our solutions and how you can start benefiting from 3D manufacturing simulation.

Why Visual Components?

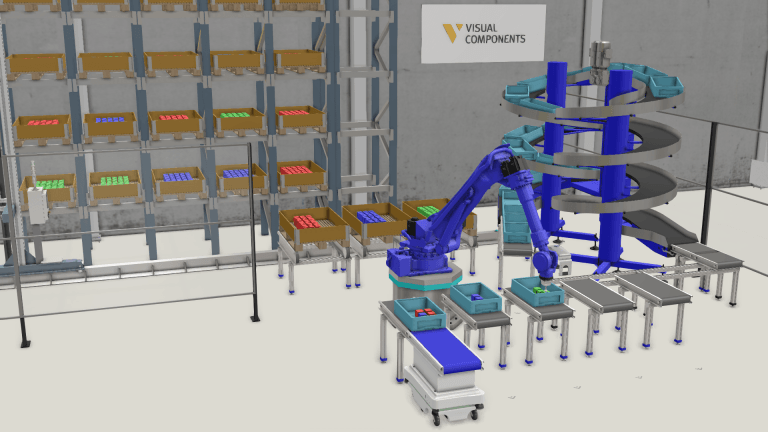

3D manufacturing simulation solutions are aplenty. But the majority do not cover every aspect of the production system lifecycle, from conceptual design to performance analysis, as Visual Components does. From incremental visualization of designs to full-blown digital twin capabilities, you’re in safe hands knowing that Visual Components has all of your bases covered.

We also boast one of the most substantial libraries of pre-defined components in the industry, our eCatalog, with over 2700 components from over 50 of the largest brands in industrial automation at no extra cost. We do this to provide you with the most accurate 3D manufacturing simulation experience possible.

Business Benefits of 3D Manufacturing Simulation

Regardless of your project, 3D simulation can help.

Whether you want to reduce your environmental footprint, increase your throughput production or, on a larger scale, reduce your overall project costs, Visual Components can provide you with a plethora of data points to better optimize, with our 3D simulation technology being able to be applied to products, machinery, and equipment and to factory layouts.

3D manufacturing simulation isn’t just a tool for Engineering and Operations though. It’s also a tool that lets business leaders calculate ROI, giving them insights into how money is being spent and, more importantly, how money is earned back.

How Has the Manufacturing Industry Changed in Recent Years?

Over the last couple of years, it’s been hard not to notice how manufacturing has changed. Supply chain issues were brought into the limelight, reshoring started becoming a serious option for manufacturers in places like the US, and efforts started being made to change the way we do business in general.

So, how does 3D manufacturing simulation fit into this deeply complex puzzle? Well, in many ways. 3D simulation allows you to:

- Get quicker results when reconfiguring your processes.

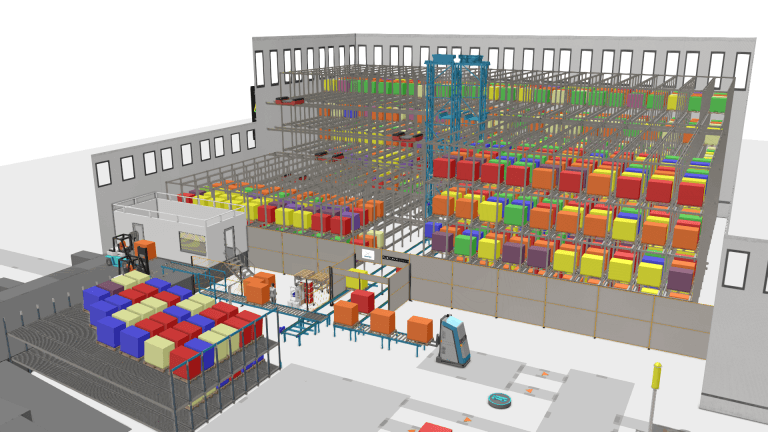

- Gain a better understanding of how different components fit together into your factory, production line, or cell.

- Gain insights into supply chain issues through efficient planning with things like intralogistics, warehousing, and the use AGVs on the factory floor, to name a few things.

How Can You Avoid Costly Mistakes?

With the advent of automation in the manufacturing industry, every manufacturer is in a rush to get the best configurations and robots and fully automate their production lifecycle. That’s easier said than done. With this rush to automate, many end up making mistakes in the process, and costly ones at that.

So, how can 3D simulation help you make the best decisions, minus the excessive capital spending that comes with constant trial and error? With simulation, you can constantly iterate your production lifecycle in a simulated environment where mistakes can be spotted without leaving the office, minimizing production disruption and enabling higher-quality programming.

This is the kind of big-picture view you can get with Visual Components. By helping you identify and focus on the critical areas, you can make better investment decisions that maximize production system performance.

How Can System Integrators Benefit from 3D Manufacturing Simulation?

If you are a system integrator and you are not using 3D manufacturing simulation, you are missing out on a lot of opportunities.

Namely, you miss opportunities to show your customers how your ideas and visions will unfold on the shop floor. You can deliver results fast and accurately, with the ability to make quick changes to your proposals if any customer query arises – making sure that once installation takes place, you do not need to worry about mistakes popping up during installation.

This is because simulation works as a tool for identifying design or layout aspects that don’t work as intended or expected. It ensures products perform correctly and so minimizes customer complaints and warranty returns. In the factory it allows early detection of mistakes in equipment design and process layout, before they become too costly and disruptive to put right.

Lastly, effective and visual 3D simulation is not only a tool for simulating factory operations but also a tool to capture your potential customer’s attention and get them interested in your proposal. We can confidently say that Visual Components has helped system integrators accelerate the sales process, increase customer commitment, improve the hit rates and, in turn, win their customer’s business.

Conclusion

Hopefully, this blog post, alongside Graham’s videos, gave you some much-needed insights into 3D manufacturing simulation and why you should consider Visual Components when adding 3D simulation into your digital manufacturing arsenal.

If you’re interested in learning more about 3D manufacturing simulation and all the things we at Visual Components can offer, please take the time to familiarize yourself with our products.

Further reading

Optimizing production lines the smart way with simulation

Manufacturers are always looking for ways to improve, whether it’s increasing throughput, reducing bottlenecks, or making better use of resources. But optimizing production lines can get complicated without the right...

Smarter warehouse planning starts with simulation

How can businesses design warehouses that operate efficiently from day one while keeping labor costs and other expenses in check? The key is smart planning and validation with simulation tools...

Comprehensive guide to input data for 3D manufacturing simulation (examples included)

If you're new to 3D manufacturing simulation, you're in the right place. This comprehensive guide will help you understand the essential input data needed to create effective simulation models. Whether...