Industry solutions

Electronics

Actively respond to new product introduction and production changes with simulation and adapt to lean production methods.

Why simulate with Visual Components?

Improve responsiveness to process changes

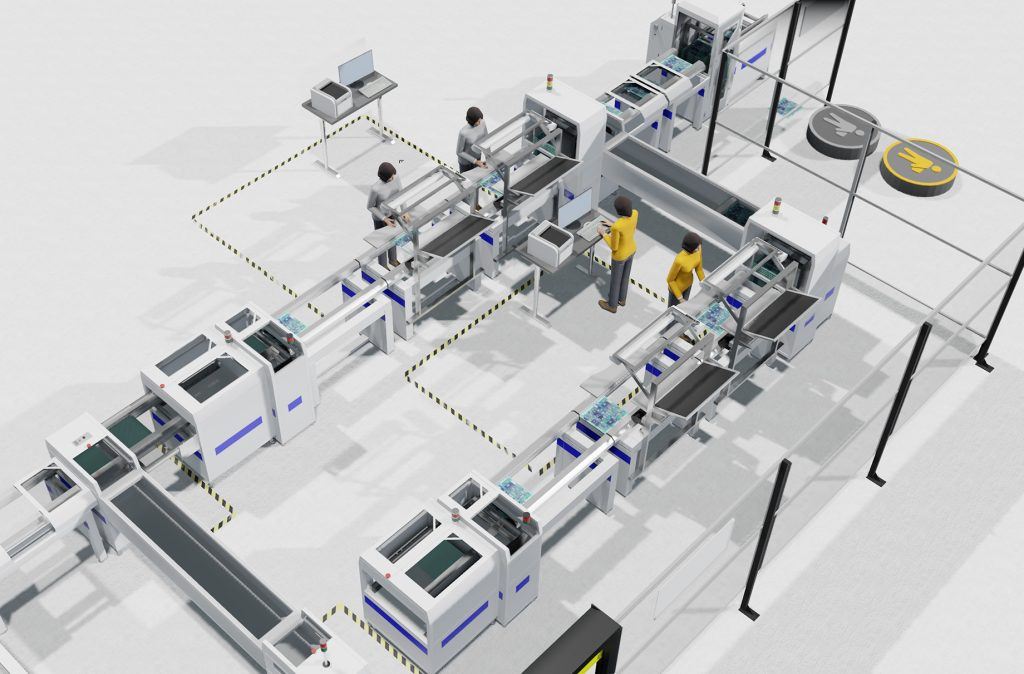

The electronics industry thrives on constant new product introductions and production changes which sometimes require modifications in the manufacturing process. With Visual Components, you can quickly respond to such changes by validating different options to find the most optimal one.

Optimize production costs

In the highly competitive electronics industry, there are continuous innovations in production technology to reduce manufacturing costs. Visual Components simulation highlights the less productive tasks, eventually optimizing your costs and faster adaptation of the latest technology.

Better adaptation of lean manufacturing

Visual Components helps you to identify and minimize the possibilities of waste whether that is related to any process unproductivity, resource utilization, scheduling errors, machine failure, and so forth.

Visual Components for the electronics manufacturing industry

Electronics is a global, fast-moving, and highly competitive industry known for rapid innovation, short product lifecycles, and complex manufacturing processes. Competition is fierce and success often depends on being first to market. These pressures not only affect the electronics manufacturers, but also machine builders and solution providers as they partner with to manufacture these products at scale.

When product lifecycles are short, automated production lines must become operational quickly to get the product to market and recoup their significant cost. Adding to the pressure, demand is variable so equipment manufacturers must incorporate flexibility. On top of this, customers concerned about sustainability are requiring manufacturers to look at every aspect of their global supply chains.

How is Visual Components used in the electronics industry?

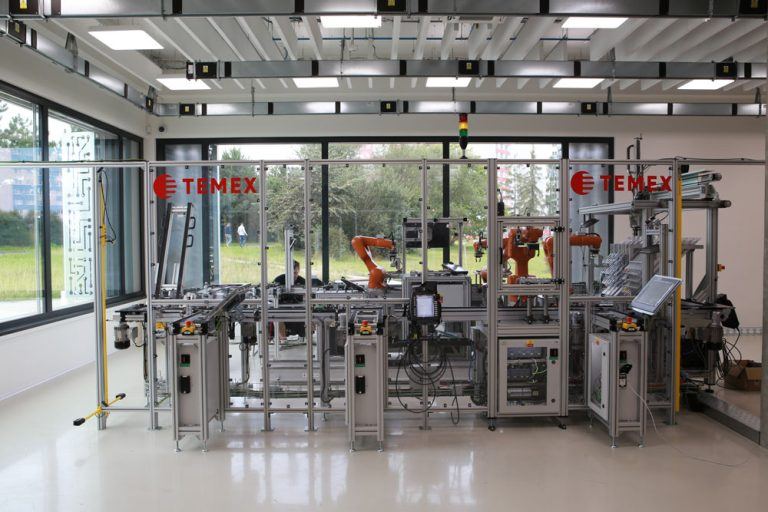

Smart Factory Project, a successful collaboration between TEMEX and VSB-Technical University of Ostrava

Read how TEMEX, a Czech-based manufacturing technology specialist, brought the Smart Factory project, a robust teaching tool at the VSB-Technical University of Ostrava, from concept to reality using Visual Components…

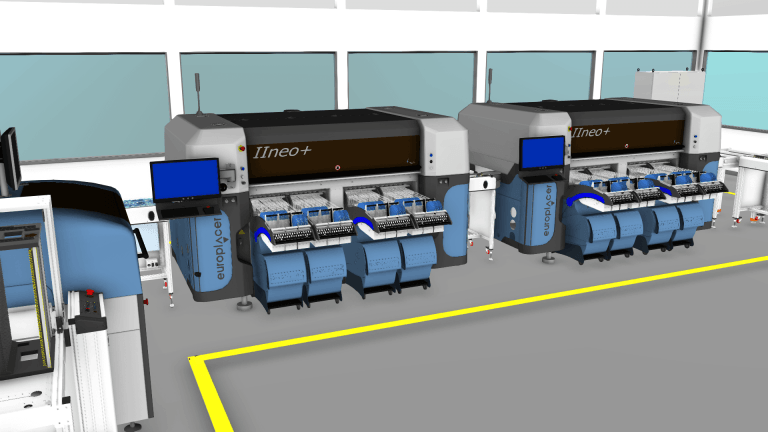

Europlacer Project Case Study: Designing Total Line Solutions in a Flash

In this case study, we'll show you how Europlacer, the world's largest independent global supplier of SMT pick-and-place machines, uses Visual Components to design and sell assembly solutions to customers…

Elm Electrical Case Study

Elm Electrical chose Visual Components as their simulation tool. Find out why!