Industry solutions

Automotive

Use one platform to design, simulate and emulate your production projects with powerful visuals.

Why simulate with Visual Components?

One platform for all use cases

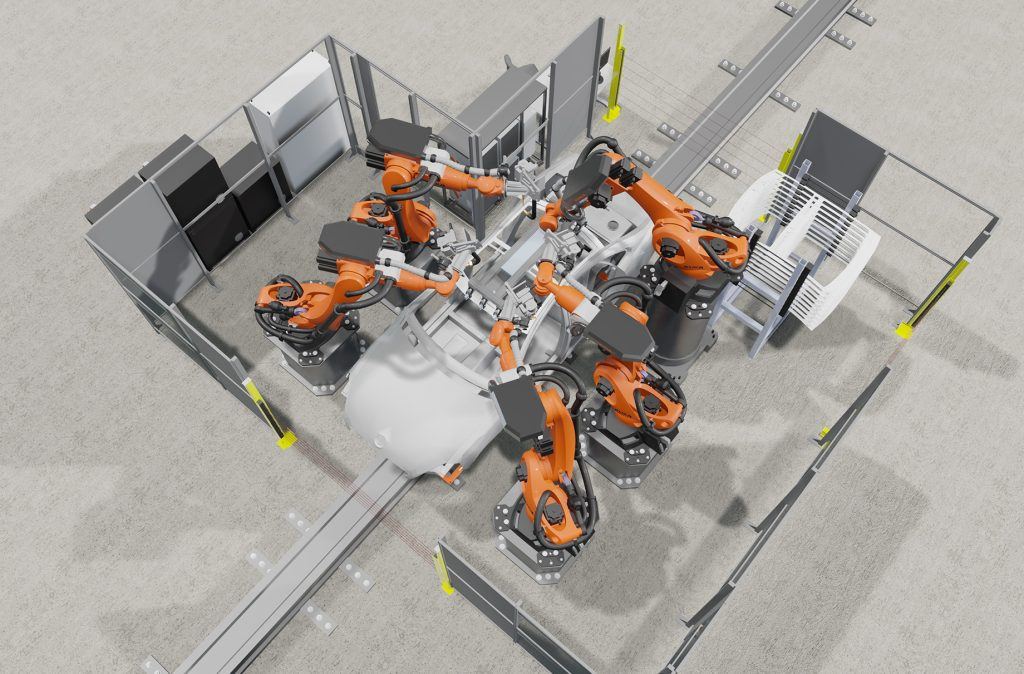

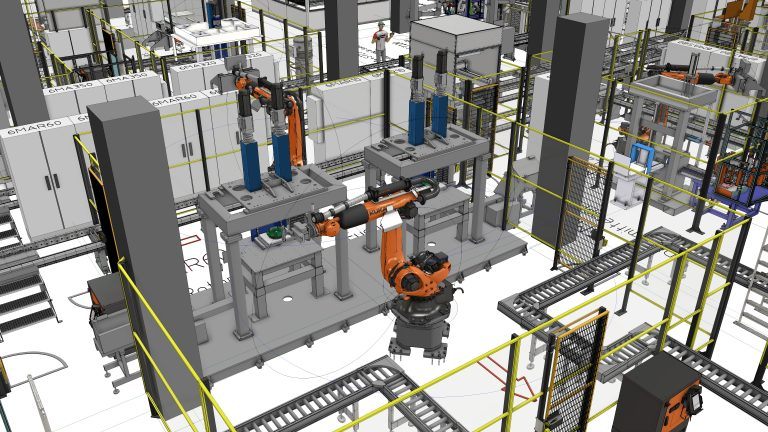

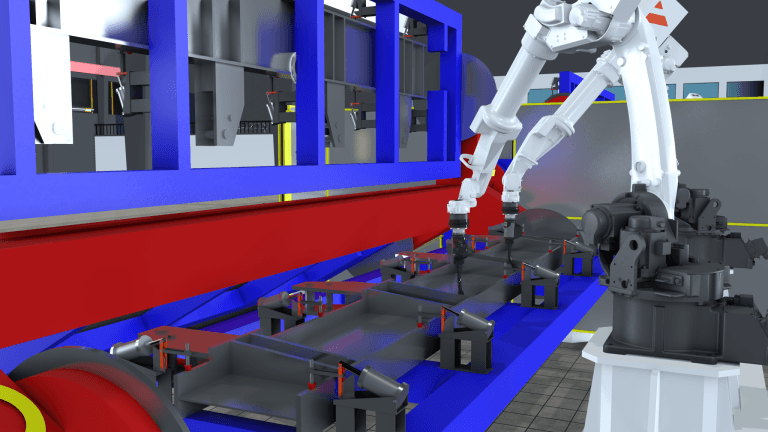

We offer offer one platform for all kinds of 3D production simulation and emulation applications in the automotive manufacturing environment – layout configuration, material flow simulation, offline robot programming, virtual commissioning tools, virtual reality experience, etc.

Improve communication across teams

An efficient automotive manufacturing system relies on transparency and clear communication across all teams. Visual Components improves that communication and collaboration by providing direct, visual, and data-driven simulated plans.

Powerful sales acceleration solution

Visual Components is a powerful simulation platform that offers all the bells and whistles for sales acceleration use cases. Design and simulate your proof of concepts in simple and easy steps, modify the designs on-the-go together with your customers and impress them with stunning visuals.

Visual Components for the automotive industry

An automobile is composed of some 30,000 components, delivered to the factory as a mixture of discrete parts and assemblies. These OEM assembly plants are served by a complex supplier network starting from Tier 1 suppliers that in turn are supplied by Tier 2’s who get their materials from Tier 3’s.

Forecasts and schedules can shift quickly, forcing manufacturers across the automotive supply chain to change their plans. Compounding the challenge, automated production processes offer only limited flexibility. Electrification and a move to battery electric vehicles have also enforced a rethink of assembly plant operations and the supply chain.

How is Visual Components used in the automotive industry?

How EMIL SCHMID MASCHINENBAU designed a high-speed battery assembly plant with Visual Components

Facing the challenge of designing a fully automated battery assembly plant for a customer, EMIL SCHMID MASCHINENBAU turned to Visual Components. With 3D simulation and an extensive library of factory…

BENTELER rolls out the production technology of tomorrow with the help of Visual Components

Together with BENTELER Automobiltechnik, Karlsruhe Institute of Technology uses modern factory planning software from Visual Components to develop innovative production technologies.

NIMAK Case Study: There Would Be No Cars Without This Company

In this case study, we’ll show you how NIMAK GmbH, the inventor of the robot welding gun and a leading manufacturer in the field of industrial joining technology, uses Visual…