Visualizing a Successful Project’s ROI

In this article, we’ll review the importance of using valid production data for labor and staffing and capital investment decisions.

After years of research & development, design & prototyping, and market testing, your new product gets the green light for production. Marketing is forecasting demand in the hundreds of thousands of units and sales teams are collecting early order commitments. Now comes the next big challenge – getting ready for production.

An important outcome of planning is a better understanding of how production decisions and expected performance translates into financial results. One of the best ways to do this is by using simulated production data as input data for financial models. In this article, we’ll review the importance of using valid production data for labor and staffing and capital investment decisions. We’ll also talk about how you can use this data to improve financial planning.

Labor And Staffing Planning

Planning for the labor pool and identifying training areas and staffing requirements is a key consideration for a new production launch. Manual labor still represents a significant share of the cost to make most goods. So, it’s important to accurately estimate the manpower your production requires, in terms of number of resources, wage and skill brackets, and scheduling. It’s also important that this is done accurately and under realistic conditions.

Here’s an example. Time studies are frequently conducted to estimate how long it takes workers to walk a certain path, connect a component, or remove or change a part on a machine. But, sometimes these studies lack important human factors. Ever run a time study with all right-handed individuals? It’s an easy variable to overlook, but can have a significant impact on manpower estimates and production scheduling. For a 20-week production, spending 8 weeks reworking all those right handed stations could mean missing out on the impact of a strong early start to sales. For seasonal items, this could mean a total flop.

Capital Expenditure Planning

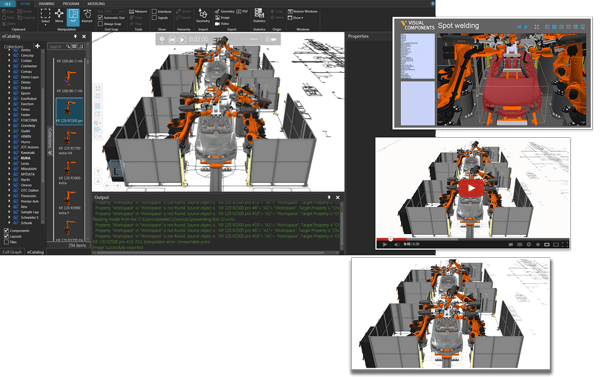

Building a new production facility or assembly line may be one of the biggest investment decisions a product company faces. It’s a major commitment that requires in depth analysis and input from several departments in the company, as its financial impact can last for years.

Purchasing new manufacturing equipment also carries with it financial and operational risks. These purchases are typically categorized as capital expenditures, which for many companies means that the final decision makers are executives with limited understanding of how the equipment will be operated on a day-to-day basis.

Your CFO may have never touched one of the precision machined products that your company manufactures, but you can be sure that they are integral to the decision to purchase a new multi-million dollar lathe that’s used to make them. They may not flip the switch but are certainly invested in seeing that the investment is operationally and financially successful. And, while they may not have the operational experience or technical acumen to catch some of the important benefits, risks, and tradeoffs, it’s critical that they’re advised on these issues by the planning team.

Can it get here in time? Will it fit? Can we change over after we are running? Will the included training “stick” with every one of our workers? The financial return on new equipment is driven by a lot of operational realities that need to be considered, modeled, and evaluated.

Production Data for Financial Planning

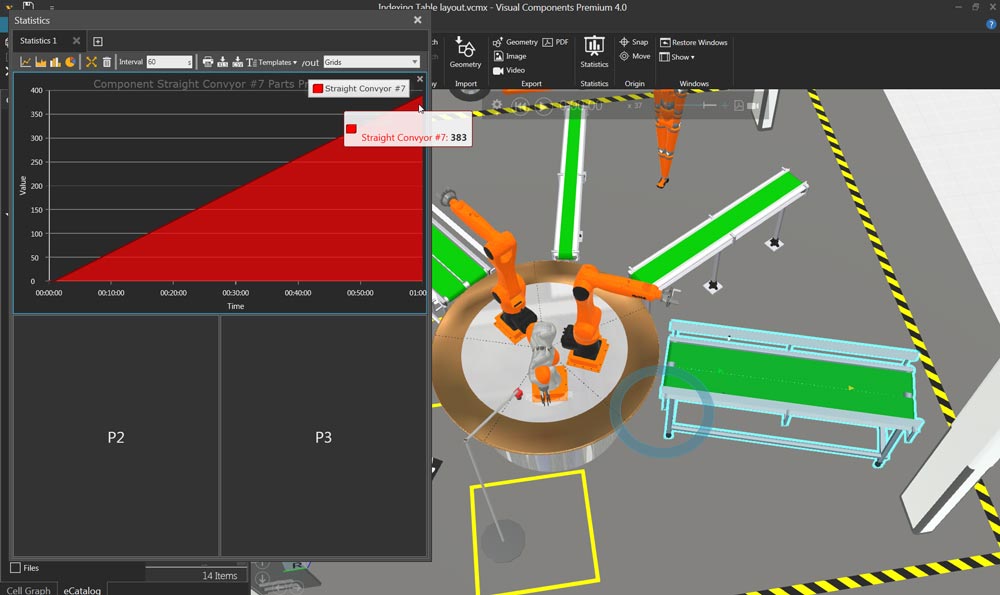

Output data from production simulations can also be used as input data to model the financial performance of productions and capital investments. Here are a few examples of how production data can be simulated to evaluate financial impact:

- Labor requirements for timing including shift length

- Ramp-up speed, output, and project length

- Capacity constraints that effect sales potential

- Capital expense ROI based on reduced failure rate or increased capacity

It’s rare that everything goes right with a product launch; demand ends up being too high or too low, a key piece of equipment breaks down, some detail in the product needs to be changed. These issues inevitably impact production and force product companies to make decisions on how to move forward. Preparing for different scenarios is critical to improve your understanding of the operational and financial impact of making changes.

Summary

When planning a new production line, it’s good to hope for the best, but important to prepare for a range of outcomes – both good and bad. This means understanding how production decisions impact financial results, modeling different scenarios, and being able to clearly communicate this information to decision makers so they make informed decisions.

Further reading

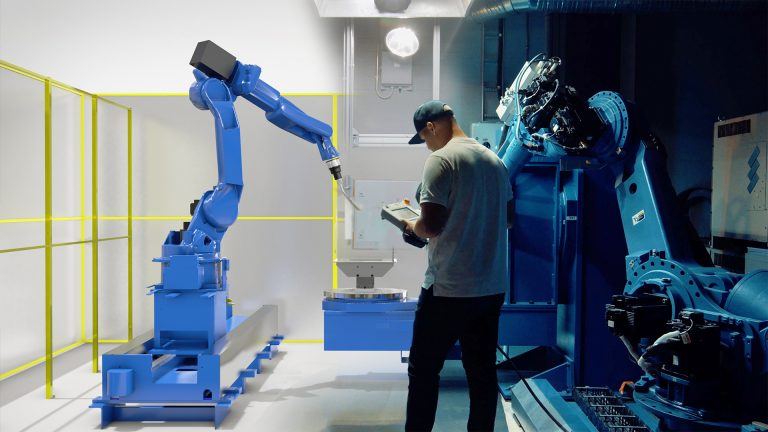

The future of automated manufacturing (and why humans still matter)

Automation in manufacturing has been evolving for decades, but its true impact isn’t in replacing people, it’s about making them more capable. We spoke with Mika Anttila, one of Visual...

Understanding digital twins in manufacturing

Digital twins go far beyond static models or simulations. They bridge the gap between virtual and physical systems, offering real-time insights and control. But with so many definitions floating around,...

Tackling the manufacturing skills shortage with simulation and robot offline programming

The manufacturing industry is grappling with a significant skills shortage, exacerbated by the pandemic and an aging workforce. According to The Manufacturing Institute, 78% of companies are concerned about this...