Tackling the manufacturing skills shortage with simulation and robot offline programming

The manufacturing industry is grappling with a significant skills shortage, exacerbated by the pandemic and an aging workforce. According to The Manufacturing Institute, 78% of companies are concerned about this trend, with 75% struggling to fill roles. This shortage threatens revenue, competitiveness, and reputation. Read on to discover how companies are tackling these challenges, what the future holds for the industry, and how some solutions might lie in simulation and robot offline programming.

Our research at Visual Components, involving over 300 manufacturing decision-makers in the UK, US, and Germany, reveals the scale of the issue. Nearly one-in-six decision-makers expect at least 41% of their workforce to leave in the next five years. Despite this, only a third consistently hire new talent, and many lack partnerships with educational institutions to build a talent pipeline.

The skills shortage impacts productivity and output, with 98% of businesses feeling the effects. Short-term consequences include increased overtime and labor costs, project delays, and profit declines. Long-term effects are even more serious, with revenue losses, decreased competitiveness, and reputational damage.

To address this, 64% of organizations are taking steps to prevent future shortages, with 87% prioritizing employee upskilling. However, many businesses feel ill-equipped to reskill and retrain employees. Simulation software and robot offline programming (OLP) are powerful tools that can significantly cut down the time and resources needed for training new employees. These technologies help reduce the risks and costs associated with traditional training methods.

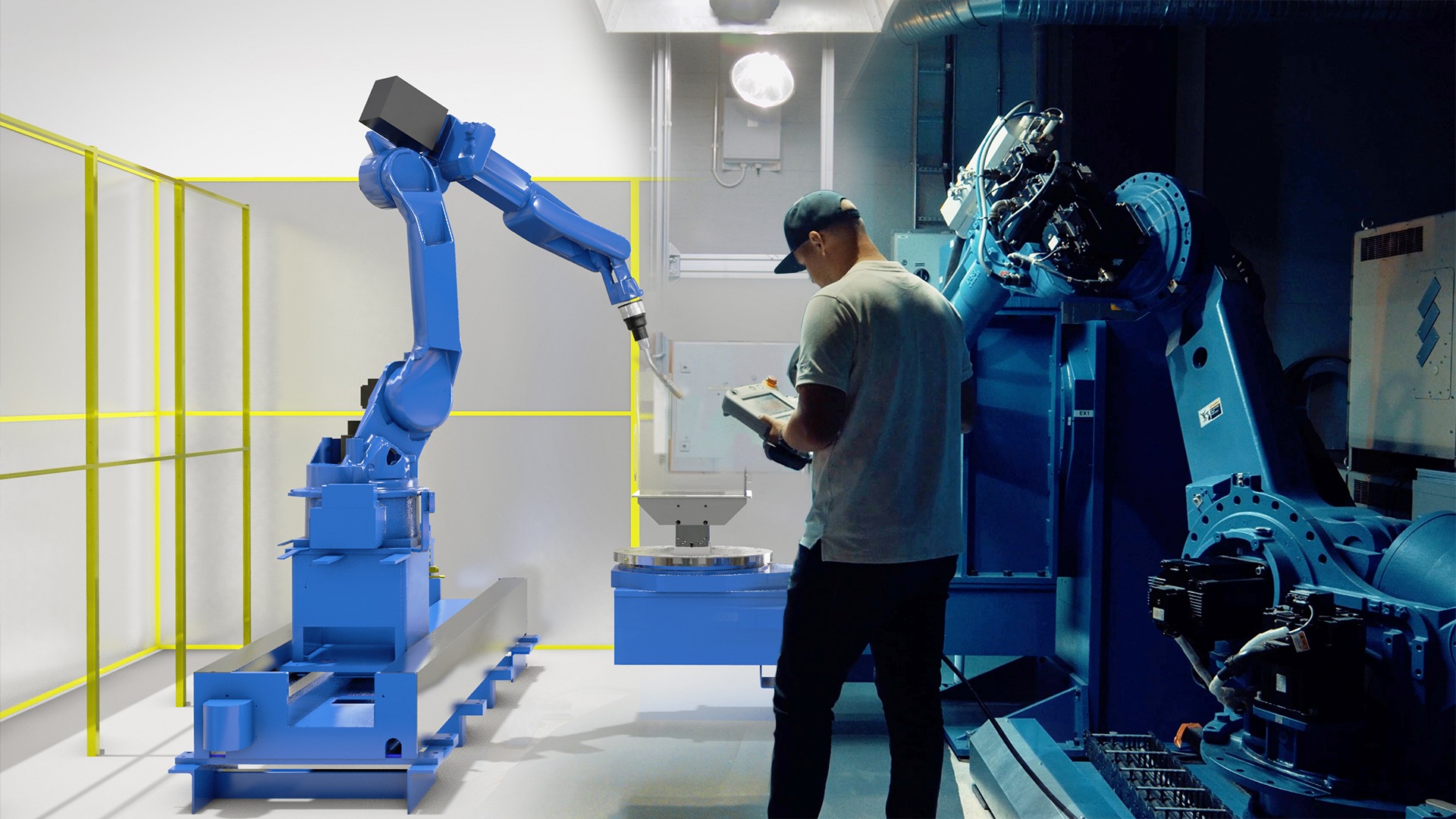

Simulation software allows staff to design, analyze, and validate manufacturing layouts in a risk-free digital environment, while OLP enables staff to deploy various robot brands for different processes. These tools support remote work and collaboration, enhancing operational resilience and open up opportunities to tap into a broader talent pool.

Investing in technologies like simulation software and OLP can help build employee capabilities and streamline operations. By adopting this approach, manufacturers can mitigate the skills shortage, maintain productivity, and ensure long-term viability.

To learn more about how our solutions can help your organization overcome the skills shortage, download the full report. Join over 2,400 pioneers in transforming your manufacturing processes with Visual Components. Let’s make your vision a reality, faster and more efficiently than ever before. Contact our team today.

About Visual Components

Founded by a team of simulation experts and amassing over 20 years in business, Visual Components is one of the pioneers of the 3D manufacturing simulation industry. The organization is a trusted technology partner to a number of leading brands, offering machine builders, system integrators, and manufacturers a simple, quick, and cost-effective solution to design and simulate production processes and offline robot programming (OLP) technology for fast, accurate, and error-free programming of industrial robots.

Further reading

The future of automated manufacturing (and why humans still matter)

Automation in manufacturing has been evolving for decades, but its true impact isn’t in replacing people, it’s about making them more capable. We spoke with Mika Anttila, one of Visual...

Understanding digital twins in manufacturing

Digital twins go far beyond static models or simulations. They bridge the gap between virtual and physical systems, offering real-time insights and control. But with so many definitions floating around,...

Boosting production line efficiency: a guide on improving production output

Production efficiency is the cornerstone of success in manufacturing. It measures the effectiveness of resource utilization in the manufacturing process, aiming to maximize output while minimizing costs and waste. The...