The digitalization of the manufacturing industry

A brief history of how digitalization has transformed the manufacturing industry.

In order to shed some light on the complexities of the manufacturing industry today, it’s enlightening to have a look at how the industry has transformed in the last 30 years. In this time, we’ve moved from designing factories and production lines on paper to precise computer simulations.

This article has been adapted from a keynote Dr. Scott E. Walter, the Chief Technical Advisor for Visual Components gave at the Manufacturing Performance Days in June 2015.

The early days of digitalization

In the mid 1980s, the American automobile industry was in trouble. Japanese cars, which were built by robots, were storming the market. Desperate to gain back their market share, American manufacturers decided to buy robots too. They soon discovered, however, that robots couldn’t replace the workers. There was no adequate planning software available and no trained workforce to use them.

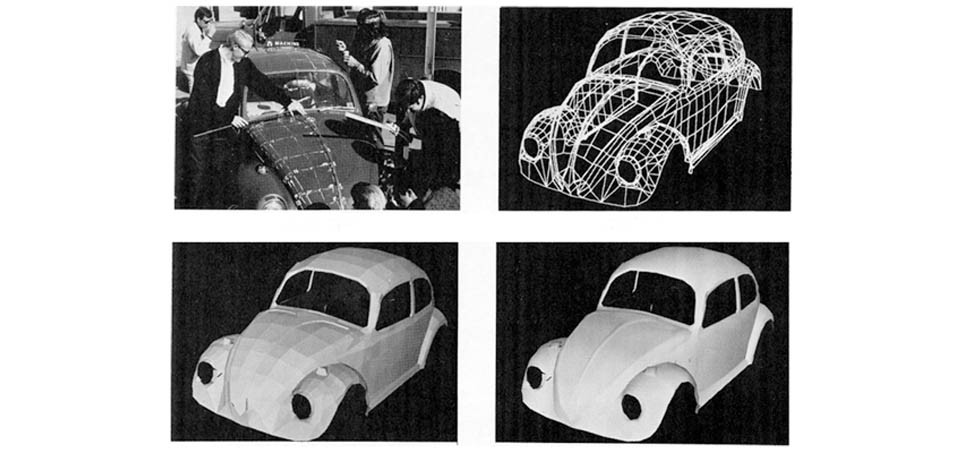

From the object to the wire-frame and polygon model with smoothed planes

(Sutherland/Sproull/Schumacker: Characterization 1974, p.5, fig.2c-f).

“We thought we could solve the robotics problem with 3D graphics,” says Scott Walter, Chief Technical Advisor for Visual Components.

Before they could get started, Walter’s team had to invent many things we now take for granted, such as lighting models, geometry kernels and user interfaces. Developers who could assist were few and far between as people with programming and computer graphics skills were difficult to find.

Robots themselves were also a problem. Each had their own language, standards for backup and a proprietary OS. Making things even more difficult, robot vendors were reluctant to share details about their robots, fearing that they would look bad or the promised cycle time would be off.

“There was no CAD of fixtures and tools, so we had to reverse engineer using a ruler and tape measure,” Walter continues.

Developing the first standards

As computers got faster and robots improved, Walter’s team was able to concentrate more on the application and less on the peripherals. Still, it was clear that the simulation could only be as good as the robot model. Since vendors would not share proprietary information with the simulation suppliers, the software was limited to reachability and feasibility studies.

There was a desperate need for industry standards. An initiative called the Realistic Robot Simulation project, or RRS, was launched in order to develop a standard protocol for simulation tools to talk with controller software. RRS was a technical success that has been adopted by the automotive industry. However, RRS modules are not readily available outside the automotive industry, and the standard is limited to two simulation brands. In other words, it is not treated like as a standard.

“Disappointingly, a standard that could solve many problems is being held hostage,” laments Walter.

Digitalization now

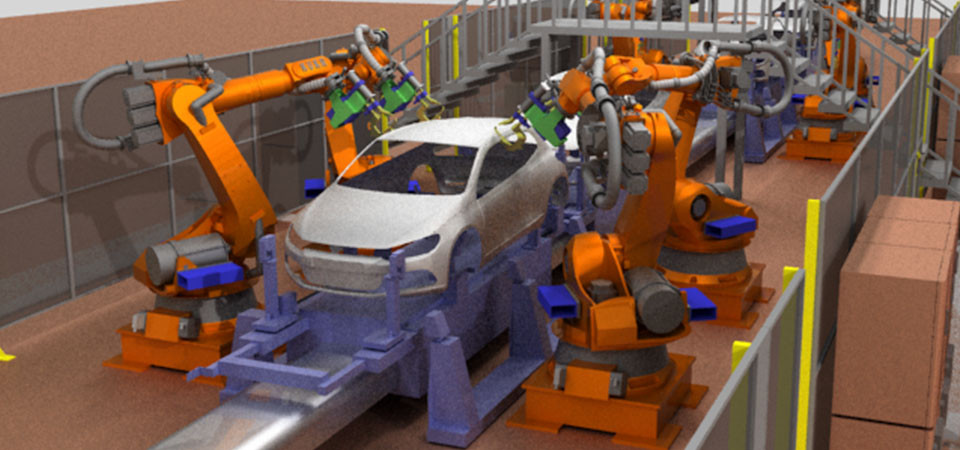

A lot has changed since the 1980’s. These days, everything is designed in CAD and the entire environment is in 3D. Finding good developers is no longer a challenge either, as powerful computers have become household items.

“Were we to start over again today, our job would be much easier,” Walter says. “We could just focus on factory simulation, because all the other stuff is available in toolkit form, and you can transfer a program to any robot with a thumb drive.”

Nevertheless, Walter still finds the current state of the industry disappointing.

“All data starts in CAD, but the information flow is where problems begin,” explains Walter.

My vision was the democratization of simulation.

Scott Walter

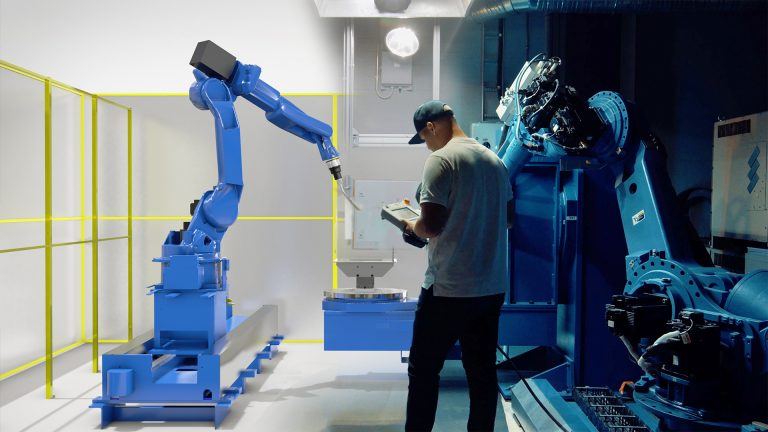

Walter believes that simulation tools should be available in every laptop. There are two reasons why they aren’t: cost and usability. The industry flagships are very expensive and require advanced training. If anyone could do the job, simulation groups would lose power.

“The problem is connectivity. We have many islands of excellence, but the data flow between those islands is poor. There are no bridges – instead there is a ferry,” illustrates Walter. “Most of time is spent messaging the data, or getting the data.”

What is the next step?

According to Walter, the solution for the connectivity problem lies in developing better standards and procedures within corporations to build simulation requirements into all stages of design, so data is seamlessly used from concept to commissioning. Existing standards should be better utilized, and new ones developed.

In order to realize the vision, we need new visionaries. In other words, we also need to attract new talent to the field of simulation.

“We now have a large talent pool of skilled programmers. So where are they?” asks Walter. “They are turning those skills to develop games, social media apps and other ‘cool’ things. We need a cool factor to attract talent.”

This is why when asked what he does, Walter instructs the other person to imagine a robot and a video game and combine them. In fact, Walter believes that since digitalization helps design the factories that make phones, his job is actually much more interesting than developing apps that just make money.

“Digitalization helps make stuff,” he says. “How cool is that?”

Further reading

The future of automated manufacturing (and why humans still matter)

Automation in manufacturing has been evolving for decades, but its true impact isn’t in replacing people, it’s about making them more capable. We spoke with Mika Anttila, one of Visual...

Understanding digital twins in manufacturing

Digital twins go far beyond static models or simulations. They bridge the gap between virtual and physical systems, offering real-time insights and control. But with so many definitions floating around,...

Tackling the manufacturing skills shortage with simulation and robot offline programming

The manufacturing industry is grappling with a significant skills shortage, exacerbated by the pandemic and an aging workforce. According to The Manufacturing Institute, 78% of companies are concerned about this...