3D production simulation today

Find out how the field of 3D simulation has been developing in recent years.

Production simulation has come a long way

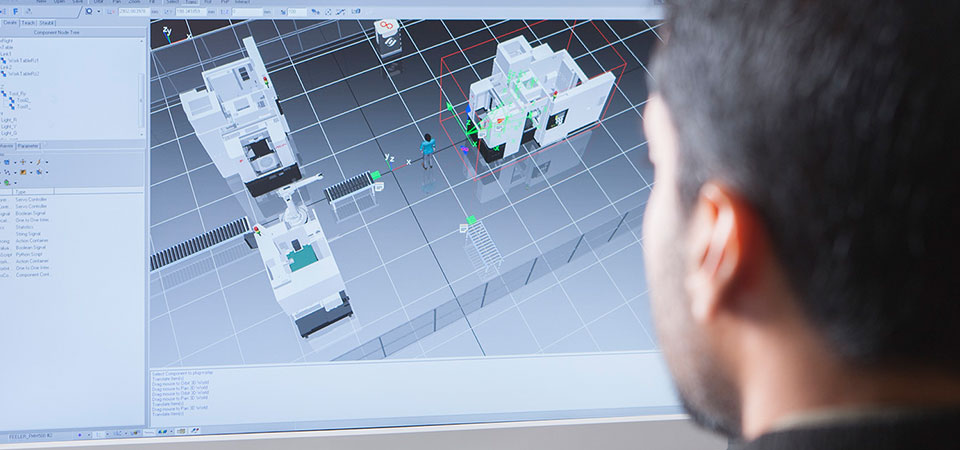

Production simulation has developed considerably in the last decades. Today manufacturers are able to put together complex 3D simulations and accurate material flow calculations with moderate levels of technical expertise. In a recent interview, Juha Renfors, CEO of Visual Components talked about the situation of the 3D simulation market.

Huge potential for small and medium sized companies

“The emergence of the Digital Factory has had a big impact on production planning,” says Renfors. “Manufacturers could, for the first time, make throughput calculations and 3D manufacturing plans virtually, without full-on physical testing.”

The Digital Factory had limitations, however. “The methods could only be used by large companies that had the means to acquire such expertise. Even then it was mostly large projects spanning over several years that were important enough for simulation,” Renfors says.

According Renfors, it is the SME’s that could most benefit from simulation software. “With fewer manual resources, the potential benefits are proportionally bigger the smaller the company. That was one of the realizations we had when we were starting out.”

3D simulation for everyone

Visual Components, has a vision of good quality simulation that could be used by anyone. “Money aside, a major limiting factor in using methods like these was the level of engineering knowledge needed to use the programs,” Renfors says.

Already 15 years ago, it was clear to us that there was a huge market for simulation products that were considerably easier to use.

Juha Renfors, CEO, Visual Components

From vision to mainstream

Today manufacturing simulation has reached the mainstream and simulation software is used far and wide. In that respect the vision of Visual Components has come true.

“Very often our newer clients have already been using some software for simulation. So to some extent companies know to look for solutions like this,” Renfors says.

“However, over the years we have developed our products beyond just material flow simulation. Our clients and partners are usually stunned by what we can provide with our technology compared to anything they have been using before.”

Ease of use and ready-made components the key to success

According to Renfors, in order to create superior results, the simulation software needs to be easily customized, powerful and easy to use.

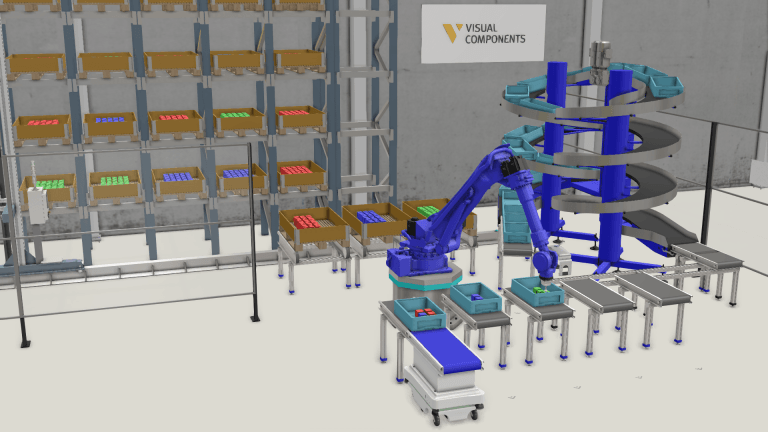

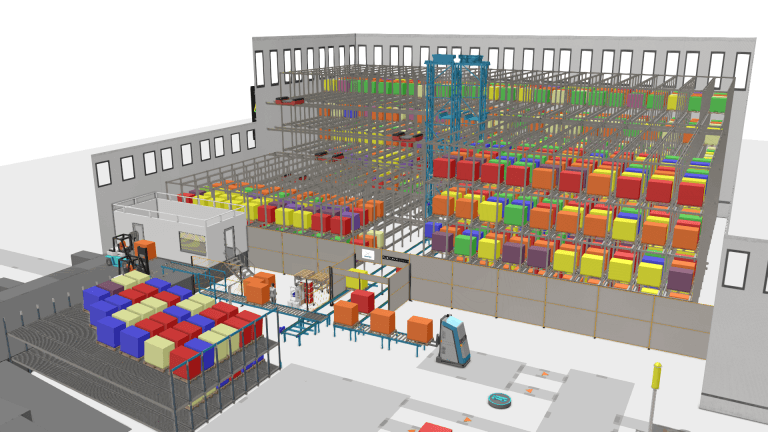

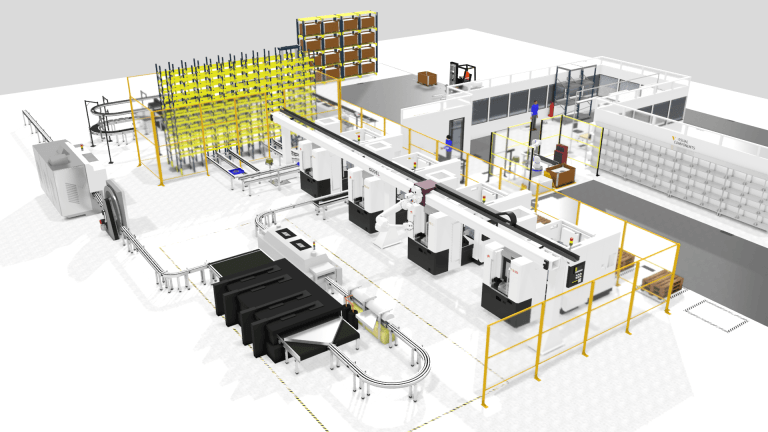

“We bring everything to one platform. In our view, 3D simulation and visualization as well as robot programming, material flow simulation and resource simulation are integrally interlinked.”

One of the features that set Visual Components apart from their competitors is their use of ready-made components.“Our clients do not need to worry about the technical intricacy of a single feature: they pick and choose a suitable component and plug it in the simulation. Right now in our constantly developing library we have around 1300 different components and over 20 robot brands to choose from.”

The design of factories in the future begins already in the sales phase

According to Renfors, one of the big changes in the future is the development of production simulation more towards sales.

“Simulation is going to be a sales acceleration tool. The value of simulation for a sales process is clear: customer commitment is reached in an earlier stage, competitive advantage is created and concept presentation is made substantially clearer.

Looking forward, simulation technology is projected to be used in every industry sector. “3D simulation has much to offer no matter what the industry is. Also, I believe we are moving away from using 3D CAD when it comes to machine builders visualizing their solutions.”

With potential across industries and functions, it is not surprising that a number of simulation technology companies are entering the lucrative market. The race for market dominance among 3D simulation service providers has begun.

Further reading

Optimizing production lines the smart way with simulation

Manufacturers are always looking for ways to improve, whether it’s increasing throughput, reducing bottlenecks, or making better use of resources. But optimizing production lines can get complicated without the right...

Smarter warehouse planning starts with simulation

How can businesses design warehouses that operate efficiently from day one while keeping labor costs and other expenses in check? The key is smart planning and validation with simulation tools...

Comprehensive guide to input data for 3D manufacturing simulation (examples included)

If you're new to 3D manufacturing simulation, you're in the right place. This comprehensive guide will help you understand the essential input data needed to create effective simulation models. Whether...