Pollux Case Study: Advancing Industry 4.0 with simulation

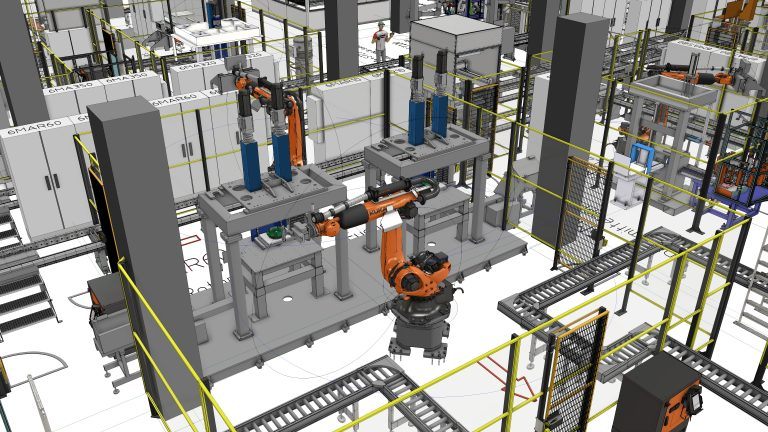

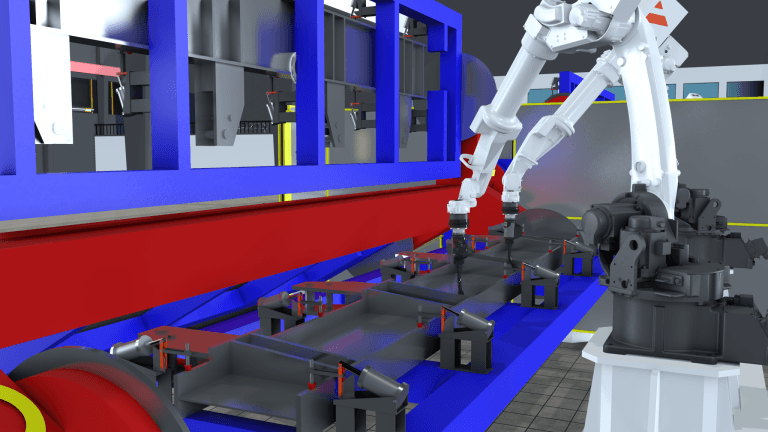

See how Pollux uses Visual Components 3D factory simulation software to make the Brazilian manufacturing industry more innovative and competitive.

Developing the next generation of engineers

Pollux is a forward-looking industrial automation company based in Brazil. Founded 20 years ago, Pollux is working mainly with automotive manufacturers, robotics and pharmaceutical companies. They are known in their home market as leaders in the use of visualization and simulation in designing and testing factory production lines.

To push the whole manufacturing industry forward, Pollux is keen to develop solutions based on the concept of Industry 4.0. As it is clear that the manufacturing revolution brought about by Industry 4.0 requires new skills from engineers, Pollux has also wanted to help foster a new generation of engineers with the know-how to put the concept into practice. Naturally, they see the use of simulation as one of the most important competences.

As a result, Pollux has launched a four-month course together with local universities, which will educate 20 students about robotics and Industry 4.0. Out of the 20 students, five will be guaranteed employment at Pollux once their course is finished. It’s clear that Pollux is investing heavily in Industry 4.0.

Pioneering simulation in Brazil

While the manufacturing industry in Brazil is massive, accounting for 28.5% of the GDP, the use of simulation in designing and improving factories and production lines has not yet been widely adopted. Pollux is determined to change this, adopting Visual Components as a sales tool when presenting new manufacturing production lines.

Not only does visualization help avoid costly errors in the sales process, it has also increased Pollux’s chances of making the sale as customers are able to get a better overview of what they will get. And once a sale is made, the implementation of the project is faster as visualization can be used as a source for simulation.

Not only does visualization help avoid costly errors in the sales process, it has also increased Pollux’s chances of making the sale as customers are able to get a better overview of what they will get.

Pollux is also acting as a Visual Components reseller in Brazil, so if you are interested in learning more, visit pollux.com.br

Further reading

How EMIL SCHMID MASCHINENBAU designed a high-speed battery assembly plant with Visual Components

Facing the challenge of designing a fully automated battery assembly plant for a customer, EMIL SCHMID MASCHINENBAU turned to Visual Components. With 3D simulation and an extensive library of factory...

BENTELER rolls out the production technology of tomorrow with the help of Visual Components

Together with BENTELER Automobiltechnik, Karlsruhe Institute of Technology uses modern factory planning software from Visual Components to develop innovative production technologies.

NIMAK Case Study: There Would Be No Cars Without This Company

In this case study, we’ll show you how NIMAK GmbH, the inventor of the robot welding gun and a leading manufacturer in the field of industrial joining technology, uses Visual...