Manufacturing experts on why early simulation and people-first automation matter

Earlier this year, Visual Components hosted a roundtable discussion titled “How to Achieve Efficiency in Production,” bringing together Finnish experts from industry and academia to share their insights on how digital tools like simulation are driving smarter decisions, safer workplaces, and, ultimately, more efficient production.

A new era of smarter manufacturing

In this blog post, we summarize the key takeaways from that roundtable conversation: why starting with digital tools like simulation early, even with imperfect data, matters, why people must remain at the center of any automation strategy, and how simulation can help justify and de-risk big decisions.

The discussion was moderated by Jesse Kamras, a well-known TV host in Finland and experienced event moderator, and featured:

- Miikka Ahola, Manufacturing Technology Director at Scanfil

- Jyrki Latokartano, Robotics Expert at Tampere University

- Mika Laitinen, Solution Sales Director at Fastems

- Juha Lantta, Automation Team Manager at Etteplan

- Mikko Salminen, Head of Global Sales at Visual Components

- Samuli Ahonen, Head of Simulation Experts at Visual Components

Start early and use simulation as a proving ground for ideas

One resounding message from the roundtable was “start as early as possible” when implementing simulation in manufacturing projects, even without perfect data.

Manufacturers often postpone or dismiss simulation as an option entirely until every input is locked down, but that mindset can hold back valuable exploration. The reality is, early-stage simulation thrives on iteration, and waiting too long means missed opportunities to test ideas, spot problems, or improve concepts before they solidify. As Samuli Ahonen, Head of the Simulation Experts team at Visual Components, explained, simulation lets teams test multiple scenarios “early on, quickly, [and] safely.” This early-stage use is less about high-stakes decision-making and more about rapid proof of concept, giving teams a safe, digital sandbox to try, fail, and iterate without real-world consequences.

This agile approach also filters out bad ideas early. If a concept fails in simulation, the only cost is time, not wasted materials, labor, or equipment. In this way, simulation becomes a core part of the design process: a tool to visualize workflows, validate space requirements, test throughput possibilities, and experiment with alternative layouts. For example, users of Visual Components often build working layouts in minutes by dragging and dropping robots, conveyors, and machines from an extensive built-in library of simulation-ready 3D components. This ease of use makes it possible to explore multiple options quickly, without writing code or creating detailed CAD drawings.

Importantly, early simulation also builds a shared understanding among engineers, planners, and stakeholders, enabling more effective collaboration from day one. By bringing simulation into the earliest phases of a project – even with incomplete information, manufacturers gain clarity faster. As projects progress, that same capability becomes a sanity check for bigger moves like investing in a new production line, reconfiguring layouts, or reshoring facilities.

High-fidelity models let teams virtually test scenarios, measure throughput, cycle times, and bottlenecks, and see likely outcomes upfront. As Mikko Salminen, Head of Global Sales at Visual Components, explained, realistic models mean “you can not only test the feasibility of your ideas, but you can also measure the performance… and [get] approval for your decisions [by seeing] the actual performance of your upcoming production systems and what might be the problems you can fix before actually building and installing your systems.” Problems caught in simulation are problems avoided during commissioning or ramp-up, saving both time and money.

Like the panellists discussed, data-driven insight is especially valuable for making the financial case for investments like automation, which can often feel like a “leap of faith”. By quantifying benefits upfront, simulation turns that leap into a calculated step backed by evidence. If a model predicts that a new robotic cell will increase throughput by 20% and pay back its cost in two years, decision-makers have a solid, data-backed rationale to proceed.

A people-first approach to automation

Technology alone doesn’t drive efficiency, people do.

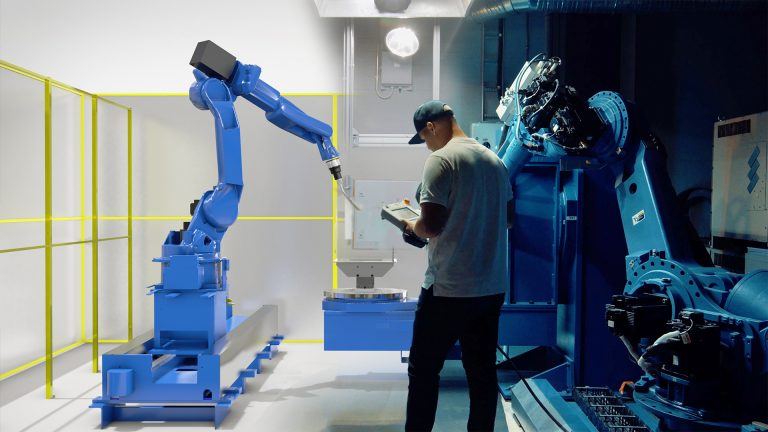

Even as factories become more automated and digitally driven, people remain the cornerstone of manufacturing success. The roundtable experts emphasized that automation should augment workers, not replace them. In fact, adopting new technology, in the words of Mika Laitinen, Solution Sales Director at Fastems, is “not any longer a choice… it’s a must” for staying competitive, but this doesn’t mean jobs simply disappear. On the contrary, automation can create opportunities for employees to take on more valuable, higher-skilled roles.

To achieve this people-first approach, the panel advised companies to introduce automation in ways that set employees up for success. That means starting with small, targeted pilots that have clear goals, rather than attempting a full-scale rollout right away. By focusing on a high-impact use case, companies can give workers the time and support to adapt, learn, and see the benefits firsthand. After all, people remain the most flexible part of any automation, as said by Miikka Ahola, Manufacturing Technology Director at Scanfil, they can adjust to new processes, respond to unexpected changes, and bring creative problem-solving where machines cannot.

Juha Lantta, Team Manager, Production Automation at Etteplan, shared an example of a manufacturer who chose to invest in robotic cells and retrain their CNC machine operators as robot operators, rather than lay them off. The company discovered that transitioning from operating traditional machinery to programming and overseeing six-axis robots was “not actually that big of a step” for their staff, and that educating their personnel in modern automation tools created more value for the business. One panelist cited studies from Denmark where each new robot led to roughly three new jobs in the company. By automating repetitive tasks and bringing new technology to the table, these firms became more competitive and expanded their operations, ultimately requiring more people in other roles.

In other words, when companies prioritize their workforce (providing training and career paths alongside new technology) automation becomes a means of upskilling employees and increasing job satisfaction, instead of a threat.

Importantly, a people-first automation strategy also improves workplace safety and ergonomics. Many routine production tasks involve risks that can be mitigated by robotics or automated assistance. Panelists noted that when you automate the heavy lifting and hazardous processes, “the risk of [a] human getting injured or having accidents… is decreased”. In fact, many manufacturers justify automation projects not only through efficiency gains, but through the promise of better health and safety for their workers. Robots can take over dangerous or physically taxing jobs – for example, lifting heavy parts or working near hazardous equipment – while people are reassigned to safer monitoring and supervisory roles. The result is a win-win: fewer injuries on the shop floor and more productive use of human talent.

With platforms like Visual Components, teams can learn the skills to experiment with robot programs, cell layouts, and automation logic virtually, without tying up production equipment or waiting for physical systems to be ready.

And this isn’t just valuable for people already working in manufacturing. As Jyrki Latokartano, Robotics Expert at Tampere University, emphasized, simulation also opens doors for students. Even without access to expensive factory equipment, they can work with realistic digital models of production systems. This prepares them with practical skills and deeper understanding before they ever step into a real factory.

Building a safer, smarter, more efficient future

Bringing the conversation full circle, the panel agreed that simulation is an ideal starting point for modernization.

It allows manufacturers to think big but start small. Building a digital model of a process is quick and low-cost, so you can test ideas in the concept phase. A simple virtual layout of a production cell or line can uncover bottlenecks or design flaws before any physical changes are made. It’s far cheaper to fix an issue in a 3D simulation, where moving a machine is just drag-and-drop than on a real factory floor after installation.

Simulation also makes it easier to align stakeholders. A realistic 3D model is far more persuasive than static diagrams and helps everyone visualize the plan. As one Visual Components user said, “a picture is worth a thousand words” when showing a new facility design.

Visual Components’ simulation platform supports this approach end-to-end, offering tools for layout planning, throughput analysis, robot programming, and virtual commissioning. With a large library of ready-made components and an intuitive interface, engineers can model new production lines in hours instead of weeks and even generate robot control programs directly from the simulation.

For more insights, take the time to watch the full roundtable discussion with industry experts:

About Visual Components

Founded by a team of simulation experts and amassing over 25 years in business, Visual Components is one of the pioneers of the 3D manufacturing simulation industry. The organization is a trusted technology partner to a number of leading brands, offering machine builders, system integrators, and manufacturers a simple, quick, and cost-effective solution to design and simulate production processes and offline robot programming (OLP) technology for fast, accurate, and error-free programming of industrial robots.

Contact us today to explore how our solutions can help your business.

Further reading

The future of automated manufacturing (and why humans still matter)

Automation in manufacturing has been evolving for decades, but its true impact isn’t in replacing people, it’s about making them more capable. We spoke with Mika Anttila, one of Visual...

Understanding digital twins in manufacturing

Digital twins go far beyond static models or simulations. They bridge the gap between virtual and physical systems, offering real-time insights and control. But with so many definitions floating around,...

Tackling the manufacturing skills shortage with simulation and robot offline programming

The manufacturing industry is grappling with a significant skills shortage, exacerbated by the pandemic and an aging workforce. According to The Manufacturing Institute, 78% of companies are concerned about this...