See how it works

Take a look through all our products have to offer. Visual Components provides an accessible yet powerful platform that helps everyone working in and around manufacturing bring their ideas to life.

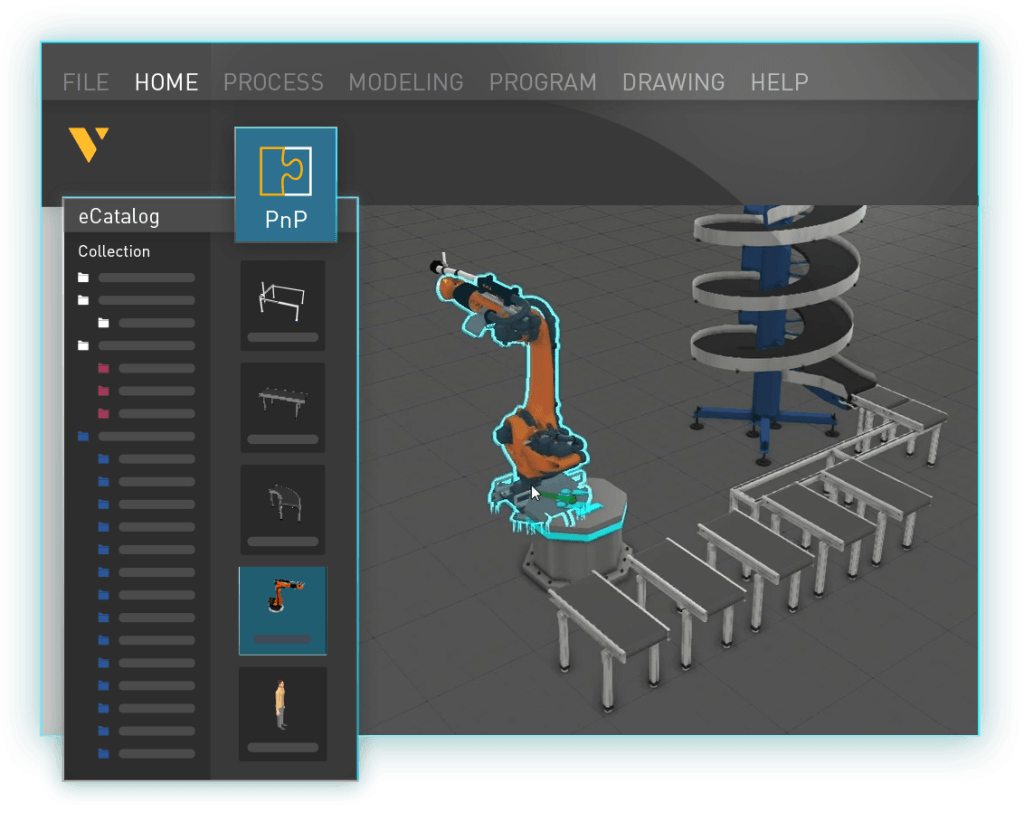

Build your concept

It all begins with layout design and building your concept. In Visual Components, you can effortlessly design your factory floor in 3D by dragging and dropping real equipment models from our vast eCatalog directly into a virtual workspace.

Validate the plan

With the initial layout in place, the next step is planning and analysis. Visual Components lets you simulate manufacturing flows to see how your line performs before a single piece of equipment hits the shop floor. You can run your process in a virtual environment and capture key metrics like throughput, cycle times, resource utilization, and a lot more, pinpointing bottlenecks and opportunities for improvement.

Bridge the digital with the physical

Armed with a fine-tuned digital model, you’re ready for virtual commissioning: the bridge between the virtual design and real operations. This is where you connect your simulated factory with actual control systems, linking PLCs and robot controllers to the 3D model to test the automation logic in real time.

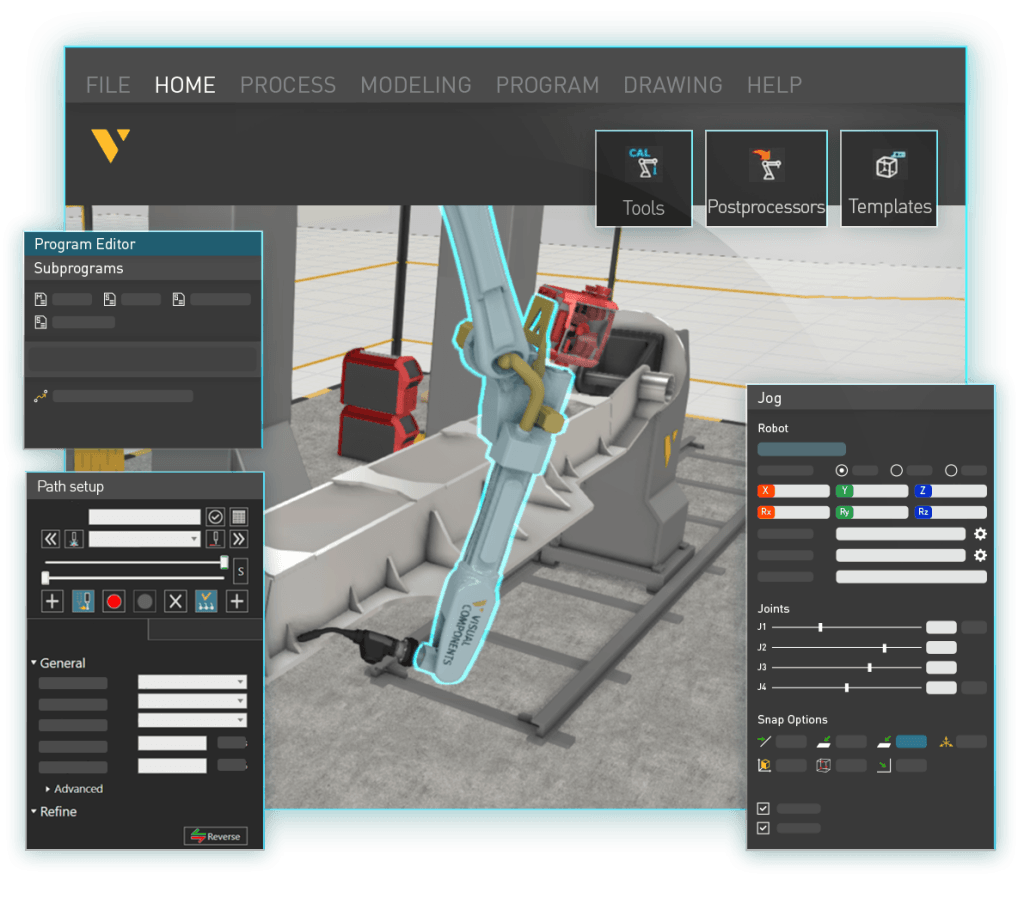

Program your robots

Take it a step further. Using Visual Components’ robot offline programming tools, you can program and fine-tune robot operations in the digital model, then deploy those programs directly to your shop-floor robots.

Explore our products

Embrace digital transformation. Designed for a wide range of manufacturing professionals, from engineers to production managers, our products help enhance every step of your production process.

Manufacturing simulation

Simple. Visual. Powerful. Design and validate new production solutions confidently with Visual Components’ 3D manufacturing simulation software.

Robot offline programming

Fast. Easy. Universally compatible. Create efficient, error-free robot programs with Visual Components’ robot offline programming software.

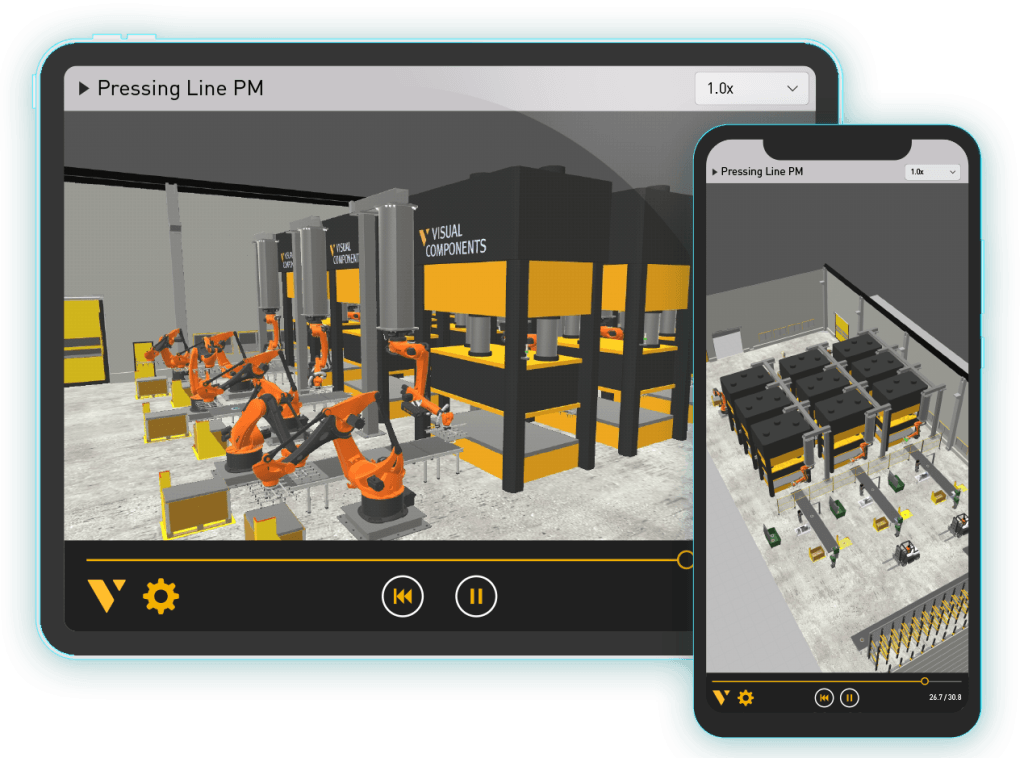

Experience

Experience manufacturing design and simulation like never before. Our line of Experience products offer various ways to showcase your simulations, including viewing them on the phone, embedding them on your website, or using immersive VR.