Factory simulation and the Internet of Things

Find out how manufacturing simulation can help your business embrace the Internet of Things.

A lot has been written in the past few years about the Internet of Things, Industrial Internet and Industry 4.0. The Fourth Industrial Revolution is said to be the biggest growth leap in human history adding a whopping 10–15 trillion $ to global GDP over the next 20 years*. We are looking at moving from 16 billion wirelessly connected devices in 2014 to a projected 40.9 billion in 2020**.

While the Internet of Things, Industrial Internet and Industry 4.0 do not mean the exact same thing; all of these concepts are closely related to each other. The concepts of Industrial Internet and Industry 4.0 are the industrial manufacturer equivalents of the Internet of Things, which usually refers to consumer-facing solutions.

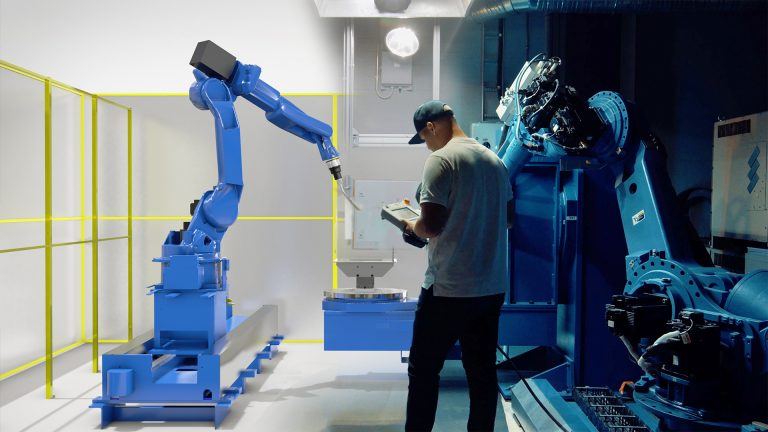

All three concepts highlight the rapid growth in number of connected devices and the data they share with each other. Whereas on the consumer side the devices can be anything from intelligent door handles to self-driving cars, on the industrial side the changes are occurring within the factories. Components of the production lines are starting to share the masses of data that they gather.

Data explosion

There are near limitless opportunities to using that data. In fact, data changes the game. We can instantly see how a factory is running and how it can be developed deeper than we currently do. For example, individual components of the production line, such as robots or conveyors can be modified and replaced as necessary. As data communication standards between components develop, production lines become less dependent on individual components from individual manufacturers.

Factory simulation has plenty to offer for companies looking to make their components more intelligent.

Mika Anttila, Chief Technology Officer, Visual Components

And this is where simulation comes in. Imagine running a real-time simulation of an entire factory in the cloud for the entire organization all over the world to observe, using any device. An engineer in Germany could easily be monitoring a simulated version of a factory in China. Through that simulation, he can then configure new components or modifications to existing components and test the impact of new components without making a huge investment. The results are visible instantly.

A modular approach

As simulations are constructed modularly, real-world intelligence is fast and easy to build in. The unique features of each component can be individually modeled and the connections between components configured. Components can be automatically set to share information with each other according to specific rules. For example, a floorboard might warn a robot that a human is approaching so that the robot can automatically adjust its movement to avoid hitting the human.

It’s likely that the standardization and integration of data between components will take some years. However, your company may start planning for the future by adopting 3D manufacturing simulation already today.

* General Electric http://www.gereports.com/post/74545267912/analyze-this-the-industrial-internet-by-the

** ABI Research https://www.abiresearch.com/press/the-internet-of-things-will-drive-wireless-connect

Further reading

The future of automated manufacturing (and why humans still matter)

Automation in manufacturing has been evolving for decades, but its true impact isn’t in replacing people, it’s about making them more capable. We spoke with Mika Anttila, one of Visual...

Understanding digital twins in manufacturing

Digital twins go far beyond static models or simulations. They bridge the gap between virtual and physical systems, offering real-time insights and control. But with so many definitions floating around,...

Tackling the manufacturing skills shortage with simulation and robot offline programming

The manufacturing industry is grappling with a significant skills shortage, exacerbated by the pandemic and an aging workforce. According to The Manufacturing Institute, 78% of companies are concerned about this...