Logimat 2025

LogiMAT provides the trade audience with a comprehensive review of all the main themes in the sector, from procurement to production and deliveries. At the start of the year international exhibitors showcase innovative technologies, products, systems and solutions for rationalisation, process optimisation and cost-reduction of in-company logistics processes. Join Visual Components at LogiMAT 2025 in Stuttgart, Germany, on March 11-13 at Hall 8 booth 8A70!

- Date: 11.3. - 13.3.2025

- Location: Stuttgart, Germany

- Keywords: industrial automation, robotics, digitalization

Join Visual Components at LogiMAT 2025 in Stuttgart, Germany, on March 11-13 at Hall 8 booth 8A70!

Speak with our experts to explore how simulation drives efficiency, productivity, and sustainability in manufacturing. LogiMAT provides the trade audience with a comprehensive review of all the main themes in the sector, from procurement to production and deliveries. At the start of the year international exhibitors showcase innovative technologies, products, systems and solutions for rationalisation, process optimisation and cost-reduction of in-company logistics processes

With 25 years of experience and trusted by over 2,400 manufacturers worldwide, Visual Components has been at the forefront of 3D manufacturing simulation, helping businesses turn their concepts into reality. Visit us at the event to see how we can help you maximize production output and robot efficiency. We look forward to seeing you at All about automation.

Meet the team

Matthias Wilhelm

Sales Director DACH and Team Lead

Matthias Wilhelm is Sales Director DACH at Visual Components and leads the German office of Visual Components GmbH based in Munich.

Together with his team he develops innovative strategies. He uses his keen instinct for solutions and added value that can be achieved through robotics and automation to advise companies and interested parties on how to achieve their goals. As a qualified mechanical engineer with a focus on the automotive industry, Matthias Wilhelm has built up an extensive network and in-depth expertise through his previous roles at companies such as Continental, ASCAD, CENIT AG and Autodesk. He uses this to successfully plan and optimize complex automation, factory and production projects.

Dennis Faber

Territory Sales Manager

Dennis Faber has been Territory Sales Manager at Visual Components in Munich since November 2024. Initially gaining practical experience as a field service technician, he progressed through After Sales Management at Körber/Seidenader to become Service Account Manager at ATS. Over the past few years, he has gained valuable experience in special machine construction, specialising in life sciences, industrial engineering, automotive and consumer goods. Through his career, he has supported customers in every possible phase of a project and has thus been able to develop an outstanding understanding of customer needs. The range of customers and industries he has served enables him to provide companies with the best possible support for their requirements with efficient, practicable and fast solutions for planning and optimising complex industrial projects.

Fastest way from concept to reality.

From the very beginning, we believed there must be a faster, easier and more collaborative way to design manufacturing systems. Today’s increasingly complex industrial landscape has shown that we are on the right path.

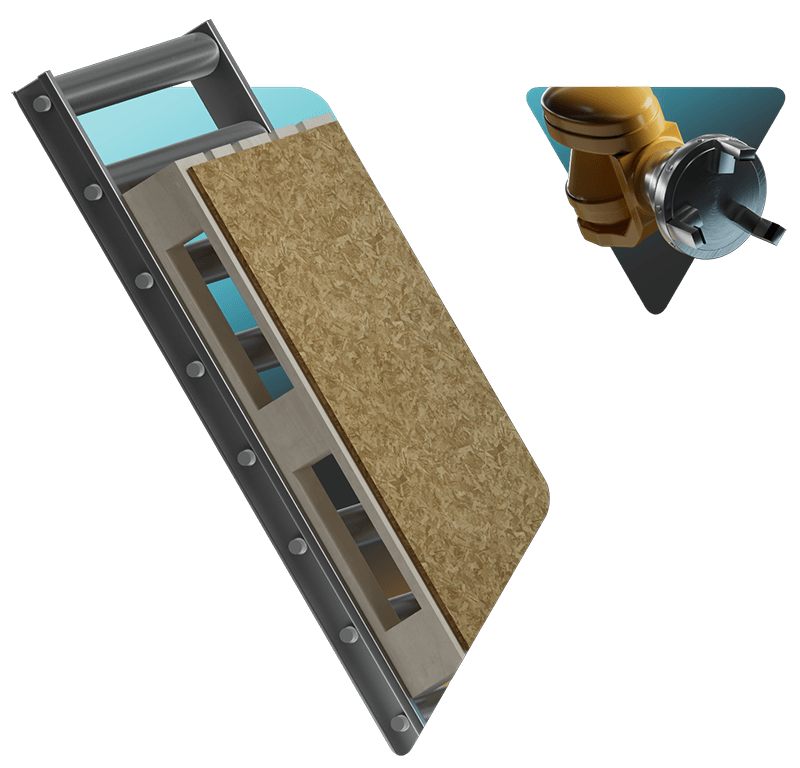

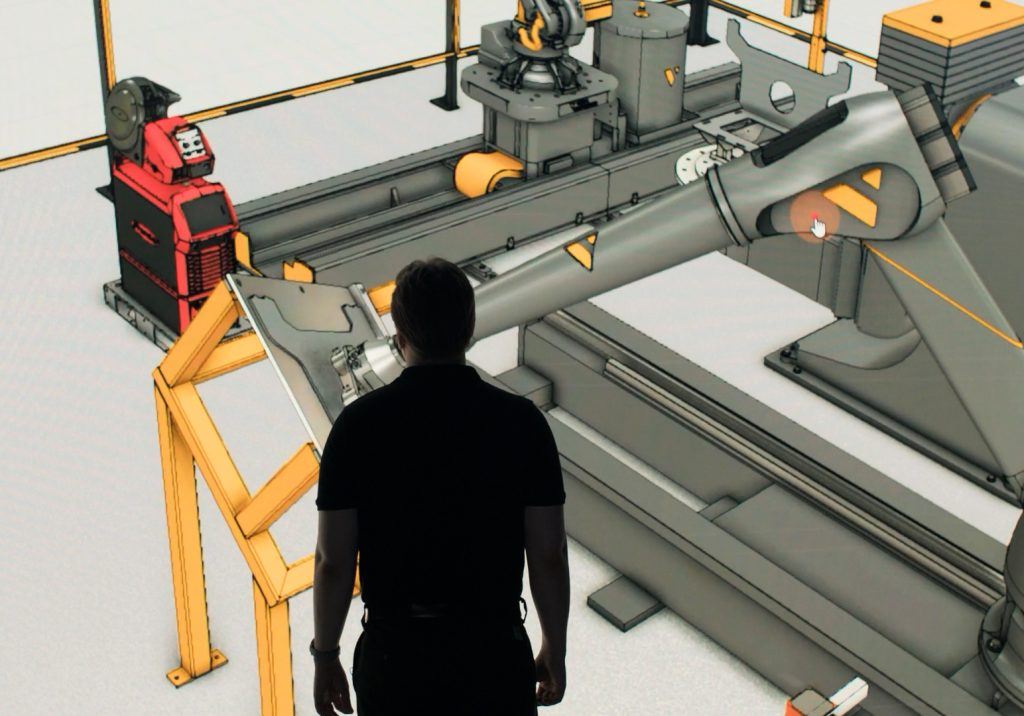

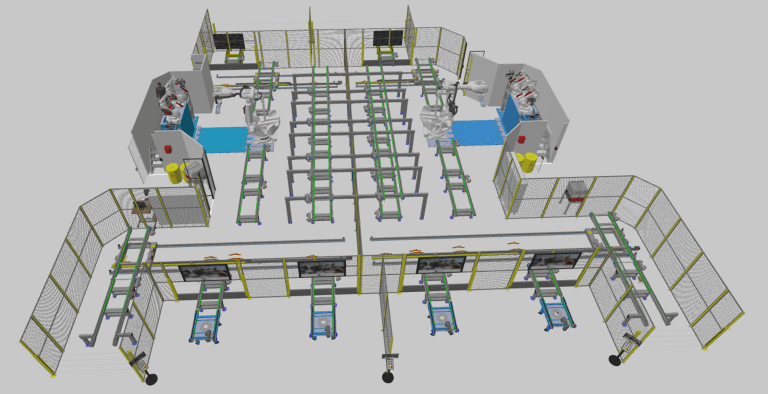

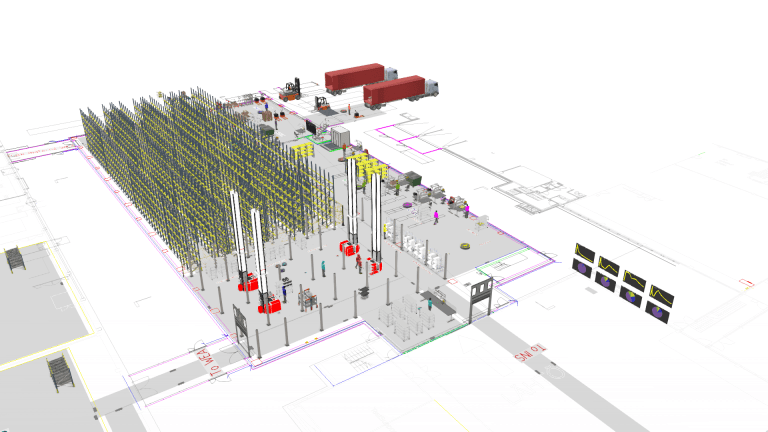

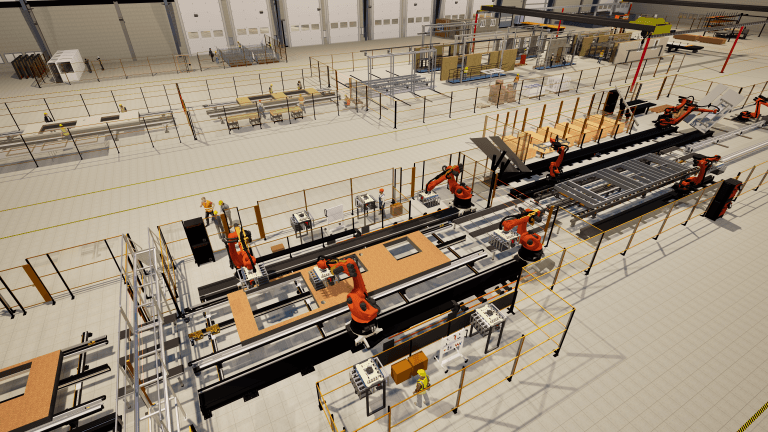

Simple. Visual. Powerful. Design and validate new production solutions confidently with Visual Components’ 3D manufacturing simulation software.

Fast. Easy. Universally compatible. Create efficient, error-free robot programs with Visual Components’ robot offline programming software.

Experience manufacturing design and simulation like never before. Our other products offer various ways to showcase your simulations, including viewing them on the phone, embedding them on your website, or using immersive VR.

Check out our industry case studies

MSK Finland advances robot cell automation and intralogistics planning with Visual Components offline programming and manufacturing simulation

MSK Finland increases efficiency in both robot cell automation and intralogistics planning using Visual Components robot offline programming (OLP) and manufacturing simulation software. By creating and validating robot programs virtually,…

Vaisala optimized and validated its new logistics center with Visual Components

Vaisala recently built a new logistics center at its Vantaa headquarters to support growing production needs. Using Visual Components’ 3D simulation platform, the automation team modeled the entire facility to…

Wiksfors uses Visual Components to bring renovation into the factory era with RenoChain

Modernizing Sweden’s aging housing stock calls for a smarter approach. With Visual Components, Wiksfors developed RenoChain, a factory-based renovation concept that uses simulation to plan and prove a faster, more…