IREX – The International Robot Exhibition

The International Robot Exhibition is highly regarded both in Japan and abroad as one of the largest robot exhibitions in the world. Visual Components is exhibiting here for the first time: visit us at booth W3-41!

- Date: 3.12. - 6.12.2025

- Location: Tokyo Big Sight, Japan

- Keywords: automation, robotics, sustainable, AI

Discover the Future of Robotic Automation at IREX 2025 with Visual Components

We’re excited to announce that Visual Components will be exhibiting at IREX – The International Robot Exhibition 2025, one of the world’s premier robotics events.

Visit us at Stand W3-41, from 3–6 December 2025 at Tokyo Big Sight, Japan, and discover how our simulation and offline programming solutions are shaping the future of robotic automation.

Why IREX Matters (Especially This Year)

IREX brings together leading innovators in robotics, automation, and AI from around the world. It’s a showcase of the latest in robot hardware, automation platforms, and smart factory solutions. For Visual Components, it’s an opportunity not just to present software — but to engage face-to-face with system integrators, robotics specialists, manufacturers, and automation decision-makers in a high-energy, forward-looking environment.

What You’ll See at Our Booth

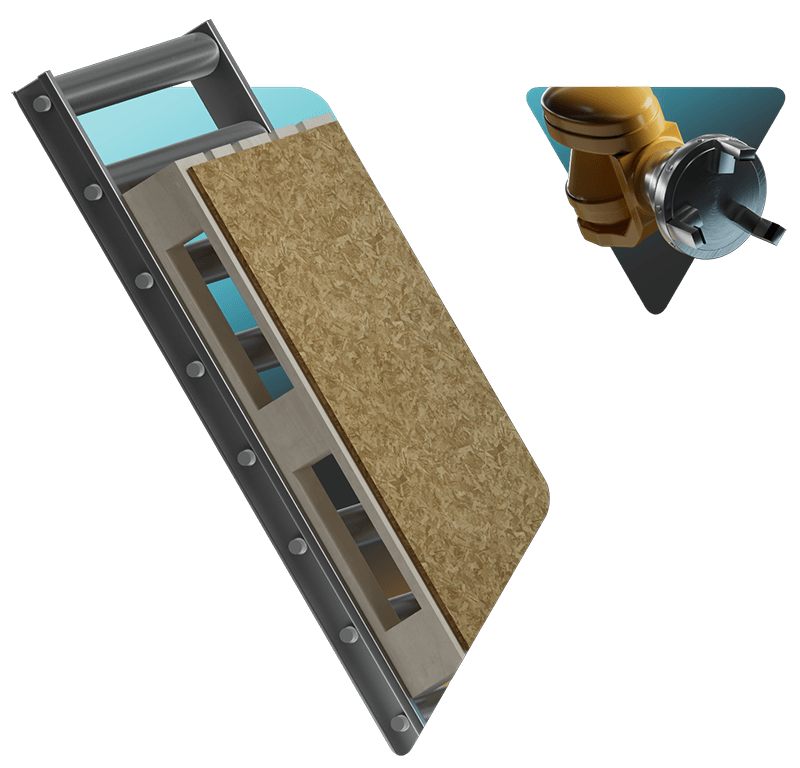

At IREX, we’ll highlight how Visual Components’ tools bridge the gap between concept and production — letting you validate, optimize, and deploy robotic systems with confidence. On display:

- Offline Programming (OLP) in action — watch live demos of how robot programs are generated, simulated, and validated virtually before hitting the shop floor.

- Multi-brand robot compatibility — see how our OLP supports major industrial robot brands, and how we’re expanding post-processors and controller integrations.

- Model-Based Definition & Automated Workflows — discover how we’re advancing automatic programming using model data, reducing manual effort.

- Use cases & live scenarios — examples of how customers apply our software to boost throughput, reduce errors, and maximize uptime.

- Product roadmap insights — sneak peeks into upcoming features, integrations, and enhancements.

We want visitors to walk away not just impressed — but with a clear idea of how Visual Components can reduce risk, accelerate deployment, and improve ROI on robot projects.

Why Visit Us — What You’ll Gain

Attending IREX is more than demo watching — it’s about strategic insight. At Visual Components booth, you can:

- Ask technical questions and workshop your own scenarios

- Explore proof-of-concept ideas with our product experts

- Compare simulation vs traditional robot programming

- Get clarity on how Visual Components fits into your automation roadmap

Meet the team

Join us in Tokyo and meet the Visual Components team at IREX 2025! We’d love to connect, share insights, and show you how our tools are transforming robot programming and simulation.

Find us at Stand W3-41, 3–6 December 2025, at Tokyo Big Sight, Japan.

Masaaki Nakamura

Country Manager, Japan

As Country Manager Japan at Visual Components, Masaaki Nakamura is spearheading the company’s expansion in Asia with the launch of its first regional office in Tokyo. Drawing on extensive experience in automation, robotics, and industrial software, he oversees business development, customer success, and local partnerships to strengthen Visual Components’ presence in Japan’s advanced manufacturing sector. His international background across Europe and Asia enables him to bridge global innovation with Japan’s manufacturing excellence.

Connect with Masaaki Nakamura on LinkedIn

https://www.linkedin.com/in/masaaki-nakamura-5123225a/

Henrik af Hällström

Application Engineer Manager

Henrik af Hällström is the Application Engineer Manager at Visual Components Japan, with 15 years of expertise in 3D factory simulation and robot offline programming.

Henrik has led the Application Engineer team, focusing on mentoring and ensuring technical quality in customer projects. He has experience in steel production welding automation and has accelerated sales by driving the business toward digital production. Henrik has also contributed to developing mobile robotics and integrating Visual Components software with PLC, VRC, and digital twin systems.

He currently plays a key role in expanding Visual Components’ presence in Japan, ensuring technical readiness and smooth collaboration between headquarters and local operations.

Kazuya Iwamoto

Sales Manager OLP, Japan

Kazuya Iwamoto has over two decades of experience in industrial technologies.

In the servo motor sector, he has helped customers to improve the precision, efficiency and reliability of their production systems.

More recently, he has focused on welding equipment sales, working closely with several kinds of customers to deliver solutions tailored to their needs.

He has striven to become a trusted partner by applying his technical knowledge and customer-centric approach.

Yuichi Ozawa

Application Engineer OLP, Japan

Yuichi Ozawa is an Application Engineer at Visual Components Japan, specializing in Offline Programming (OLP) for industrial automation.

With a strong background in simulation-based engineering, he supports customer onboarding, training, and technical guidance across Japan. His expertise in OLP and collaborative approach help manufacturers streamline automation workflows and improve production efficiency.

Fastest way from concept to reality.

From the very beginning, we believed there must be a faster, easier and more collaborative way to design manufacturing systems. Today’s increasingly complex industrial landscape has shown that we are on the right path.

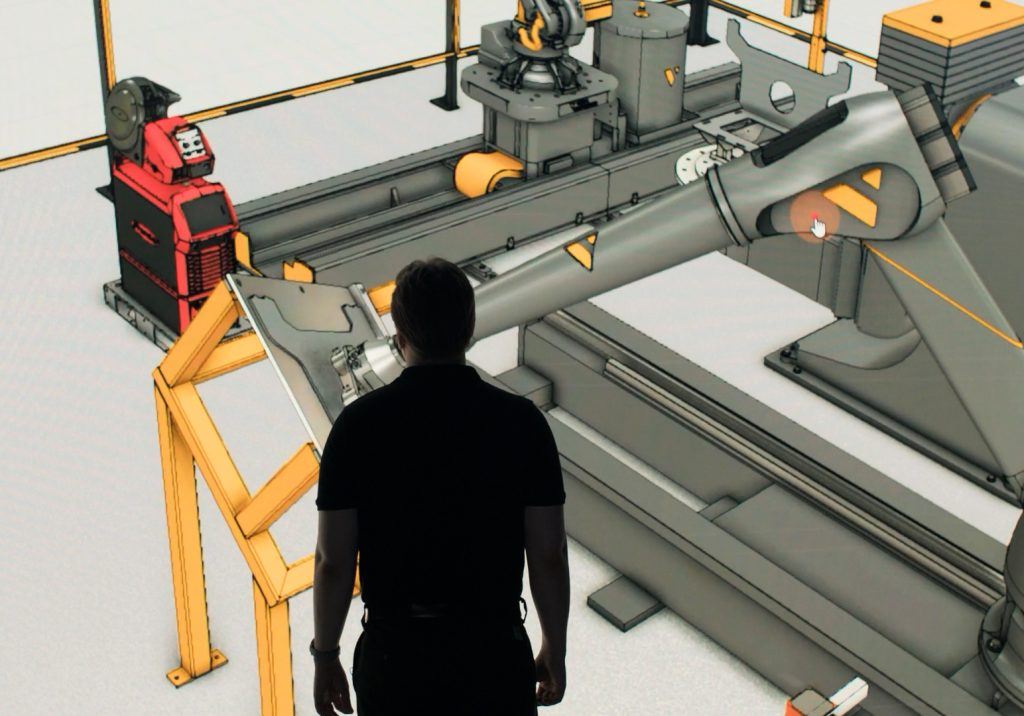

Simple. Visual. Powerful. Design and validate new production solutions confidently with Visual Components’ 3D manufacturing simulation software.

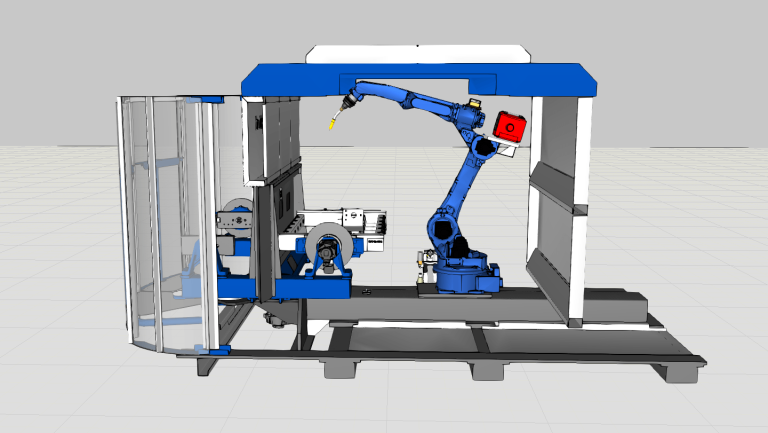

Fast. Easy. Universally compatible. Create efficient, error-free robot programs with Visual Components’ robot offline programming software.

Experience manufacturing design and simulation like never before. Our other products offer various ways to showcase your simulations, including viewing them on the phone, embedding them on your website, or using immersive VR.

Check out our industry case studies

Maximizing efficiency and ROI from day 1: Duun Industrier pre-programs a welding robot cell with Visual Components OLP

Duun Industrier, a leading Norwegian heavy machinery manufacturer, installed the Nordics’ largest robotic welding station in 2013. Utilizing Visual Components for robot programming since 2014, they commissioned a new robot…