Factory Innovation Week 2025

Factory Innovation week (FIW), held in in Osaka Japan from May 14-16, 2025, is the leading Manufacturing Industry exhibition in Japan! Visit us at booth K7-13!

- Date: 14.5. - 16.5.2025

- Location: Osaka, Japan

- Keywords: Robotics, automation, digitalisation, sustainable manufacturing

Factory Innovation Week 2025

We are thrilled to announce that Visual Components will be participating in Factory Innovation Week 2025 in Osaka, Japan. This marks our first time taking part in a tradeshow in Japan and Asia with our own stand. Factory Innovation Week is a premier event for industry professionals to explore the latest advancements in manufacturing technology, robotics, factory automation, and digitalization.

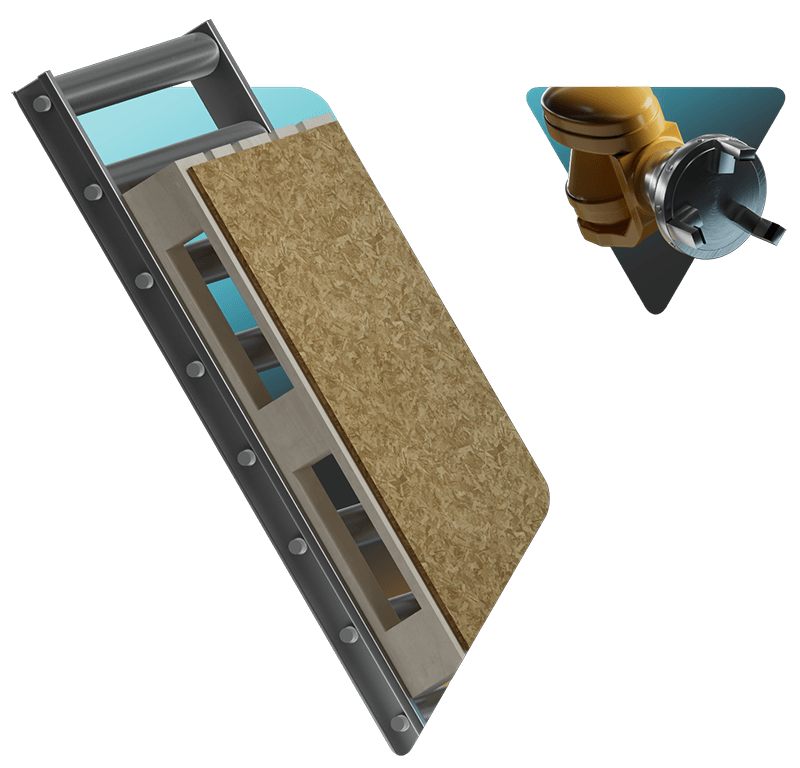

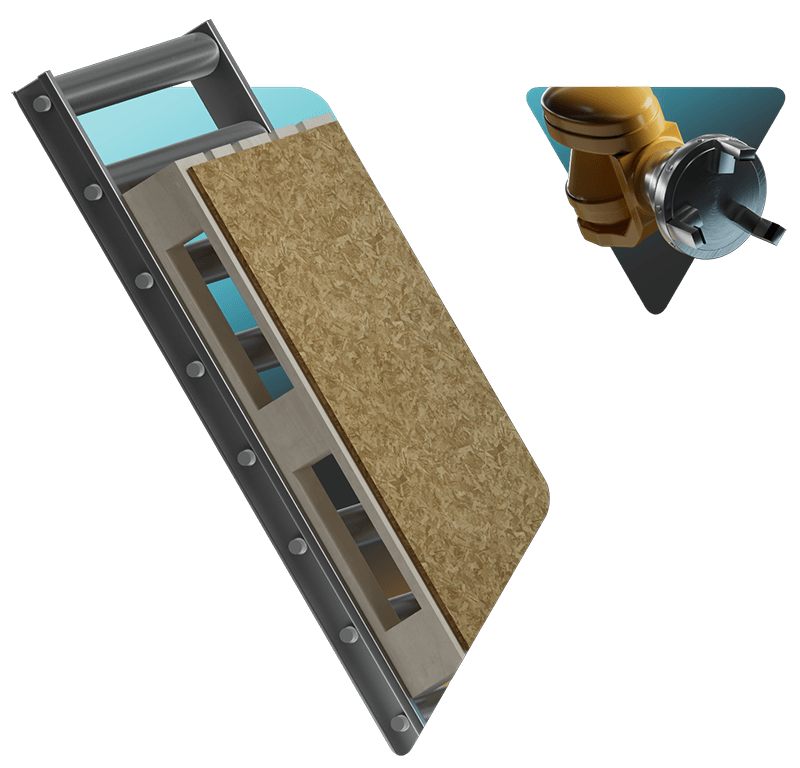

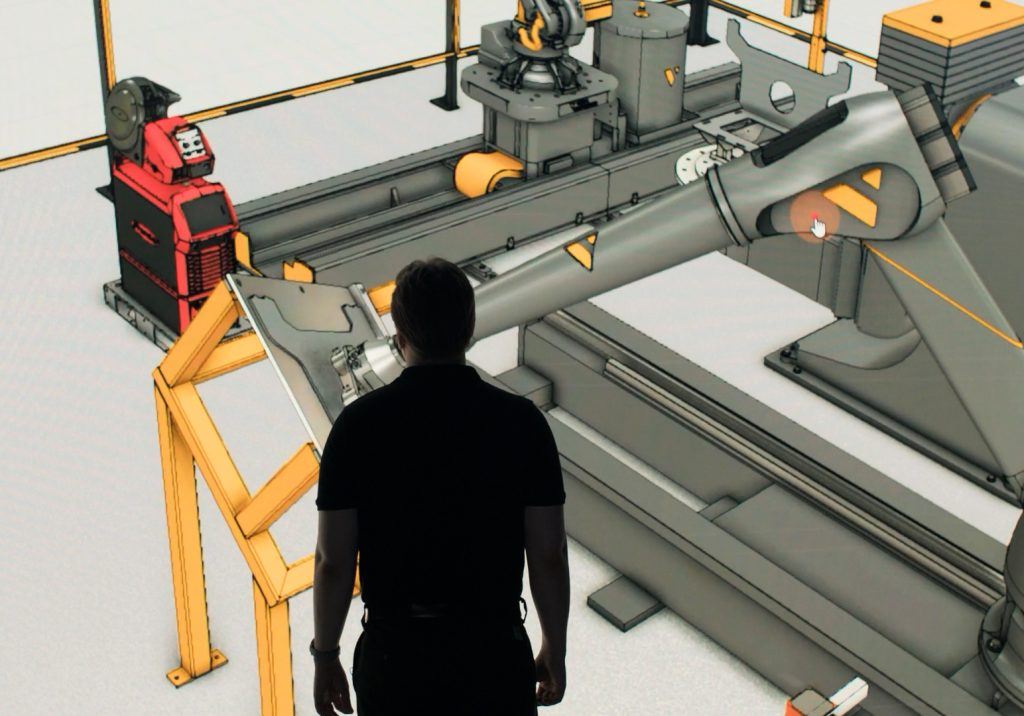

Special emphasis is placed on modern production equipment in robotics, digitalization, automation, and other technology for smart factory solutions. By visiting our booth, you will have the chance to see firsthand how our innovative tools can transform your manufacturing operations. Our best-in-class offline programming software makes robot programming accessible to users without extensive technical knowledge. It enables companies to create efficient, error-free robot programs on computers using 3D CAD data without interrupting production lines. The fast and easy OLP software supports all levels of automation, from one-click programming to fully automated model-based definition. It is compatible with major industrial robot brands, processes, and complexities, helping our customers to maximize quality, robot utilization rate, and production output.

This participation also aligns with our recent expansion into Japan. Visual Components has opened a new office in Tokyo, marking a significant milestone in our commitment to delivering cutting-edge automation technology and exceptional service to our customers and partners in Japan. The Tokyo office will serve as a hub for our operations in Japan, enabling us to better support local industries, including automotive, electronics, machine tool builders, and advanced manufacturing.

Don’t miss this opportunity to discover the future of manufacturing with Visual Components at Factory Innovation Week 2025 in Osaka, Japan. We look forward to seeing you there at booth K7-13!

Meet the team

Masaaki Nakamura

Country Manager, Japan

As Country Manager Japan at Visual Components, Masaaki Nakamura is spearheading the company’s expansion in Asia with the launch of its first regional office in Tokyo. Drawing on extensive experience in automation, robotics, and industrial software, he oversees business development, customer success, and local partnerships to strengthen Visual Components’ presence in Japan’s advanced manufacturing sector. His international background across Europe and Asia enables him to bridge global innovation with Japan’s manufacturing excellence.

Connect with Masaaki Nakamura on LinkedIn

https://www.linkedin.com/in/masaaki-nakamura-5123225a/

Get here your free ticket for “Factory Innovation Week 2025”

Fastest way from concept to reality.

From the very beginning, we believed there must be a faster, easier and more collaborative way to design manufacturing systems. Today’s increasingly complex industrial landscape has shown that we are on the right path.

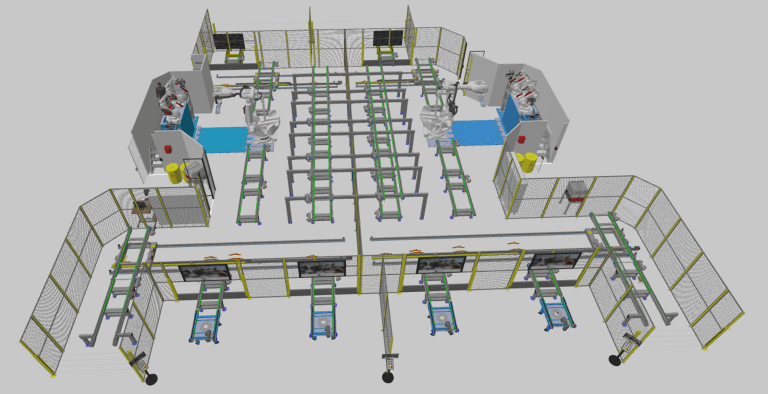

Simple. Visual. Powerful. Design and validate new production solutions confidently with Visual Components’ 3D manufacturing simulation software.

Fast. Easy. Universally compatible. Create efficient, error-free robot programs with Visual Components’ robot offline programming software.

Experience manufacturing design and simulation like never before. Our other products offer various ways to showcase your simulations, including viewing them on the phone, embedding them on your website, or using immersive VR.

Check out our industry case studies

MSK Finland advances robot cell automation and intralogistics planning with Visual Components offline programming and manufacturing simulation

MSK Finland increases efficiency in both robot cell automation and intralogistics planning using Visual Components robot offline programming (OLP) and manufacturing simulation software. By creating and validating robot programs virtually,…

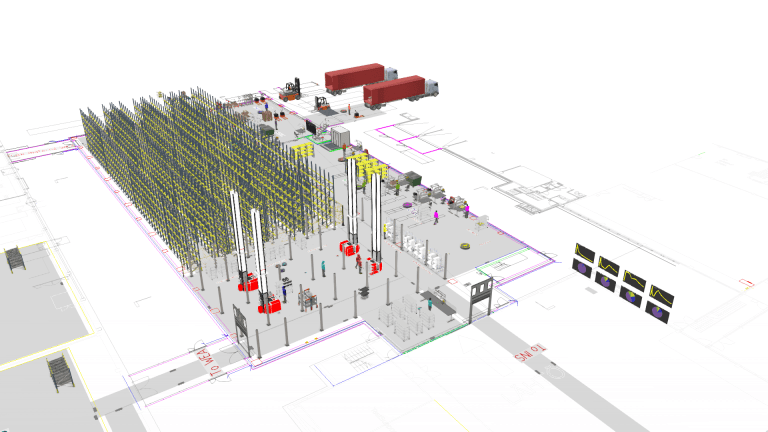

Vaisala optimized and validated its new logistics center with Visual Components

Vaisala recently built a new logistics center at its Vantaa headquarters to support growing production needs. Using Visual Components’ 3D simulation platform, the automation team modeled the entire facility to…

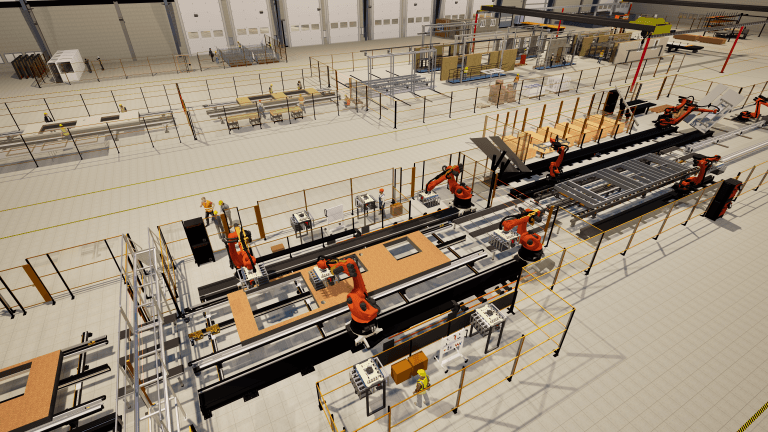

Wiksfors uses Visual Components to bring renovation into the factory era with RenoChain

Modernizing Sweden’s aging housing stock calls for a smarter approach. With Visual Components, Wiksfors developed RenoChain, a factory-based renovation concept that uses simulation to plan and prove a faster, more…