Wiksfors uses Visual Components to bring renovation into the factory era with RenoChain

Modernizing Sweden’s aging housing stock calls for a smarter approach. With Visual Components, Wiksfors developed RenoChain, a factory-based renovation concept that uses simulation to plan and prove a faster, more efficient way to renovate homes at scale.

Using simulation to rethink how Sweden renovates its aging housing stock

Sweden’s Million Program, a government-led housing initiative between 1965 and 1974, aimed to build one million new homes in just ten years to address a nationwide housing shortage. The program reached it’s goal of producing over a million apartment, but today many of those buildings are in urgent need of renovation, especially when it comes to energy performance and occupant comfort. But traditional renovation methods are hard to scale: they’re slow, expensive, and disruptive to residents.

Wiksfors Technology, an engineering firm focused on sustainable industrialization, is one of the lead partners behind RenoChain, a long-term development initiative exploring how to make large-scale renovation faster, more predictable, and less resource-intensive. The project, developed together with Sustainacon AB, Swedish Energy Agency, Säfflebostäder AB, and others, combines building scanning, automated design, factory production, and on-site assembly into one connected workflow.

Visual Components plays a key role in making that vision possible, supporting everything from factory validation to installation sequencing and stakeholder communication.

Simulating the RenoChain workflow from factory to site

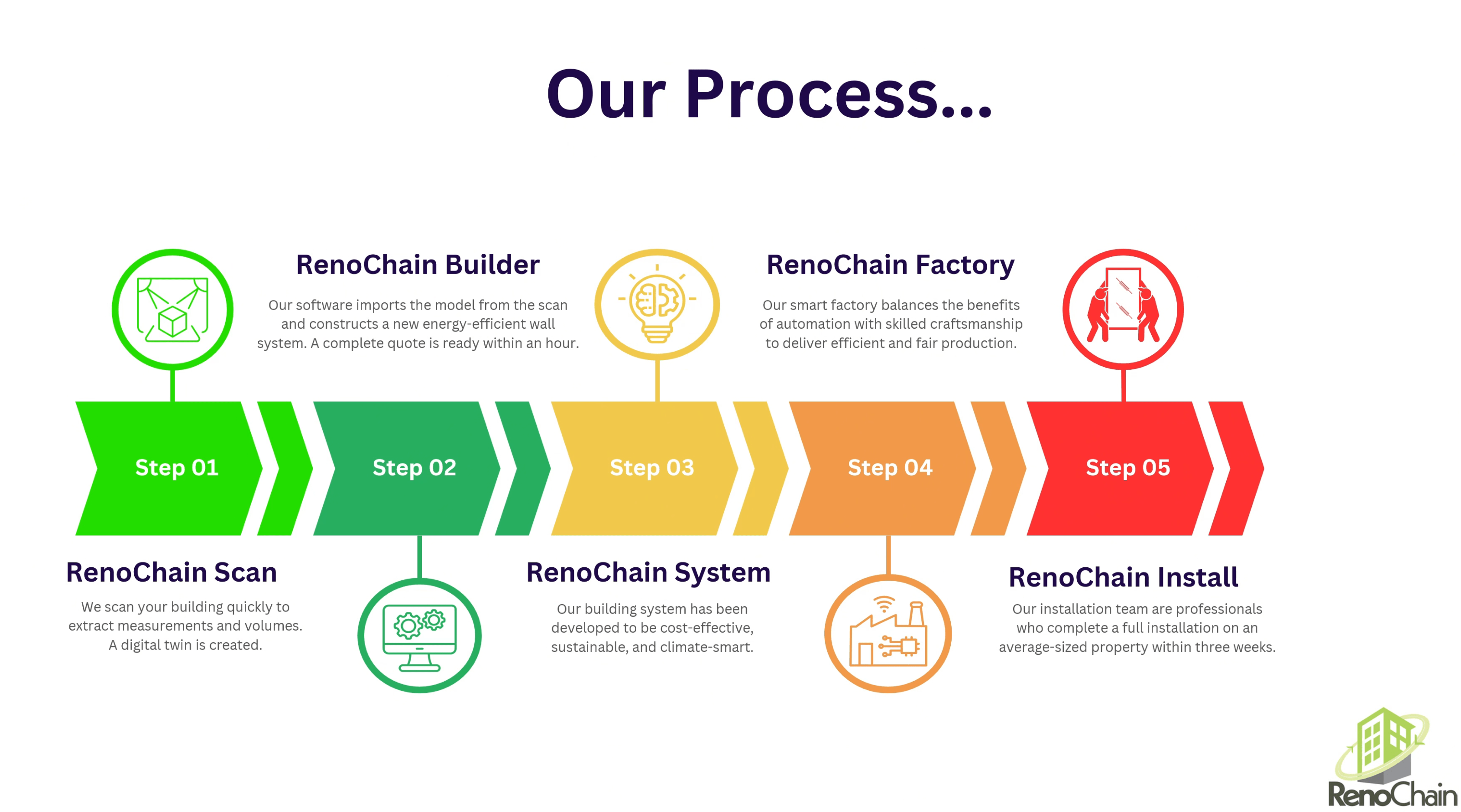

RenoChain is built around a simulation-ready digital thread. It starts with a 3D laser scan of a building (RenoChainScan), which feeds into Wiksfors’ own RenoChainBuilder software, a design tool that automatically generates a complete renovation model, including energy performance, cost estimates, material planning, and scheduling. Next comes RenoChainSystem, a modular construction system that applies standardized components like façades, roofs, and walls to configure the renovation design. From there, the process moves into Visual Components.

Renovating one building at a time is not enough. To scale, we need tools that let us design, test, and optimize entire factories virtually. Visual Components allows us to simulate that journey end-to-end, giving confidence to everyone from operators to housing authorities.

Pontus Wikholm, CEO, Wiksfors Technology

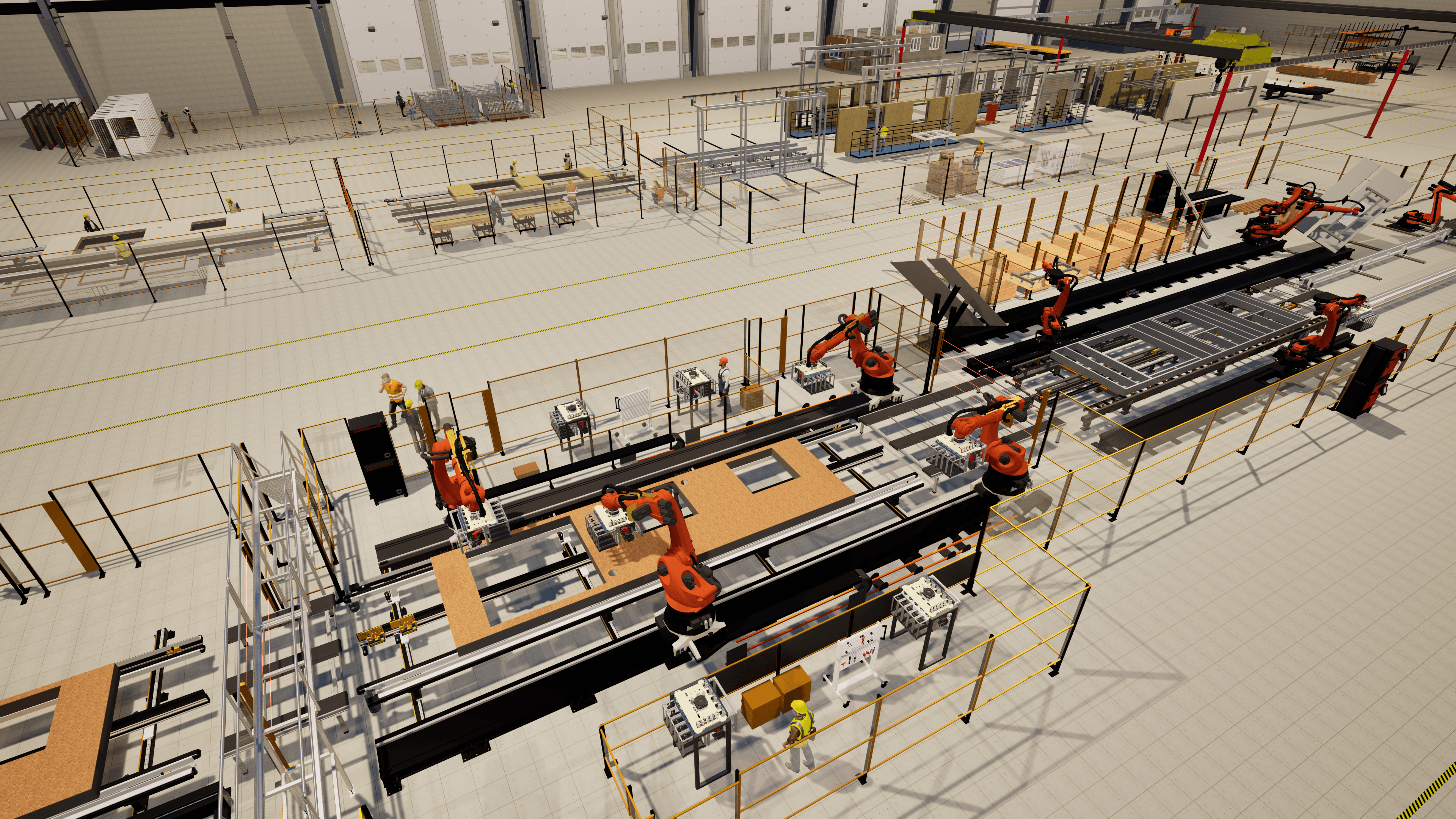

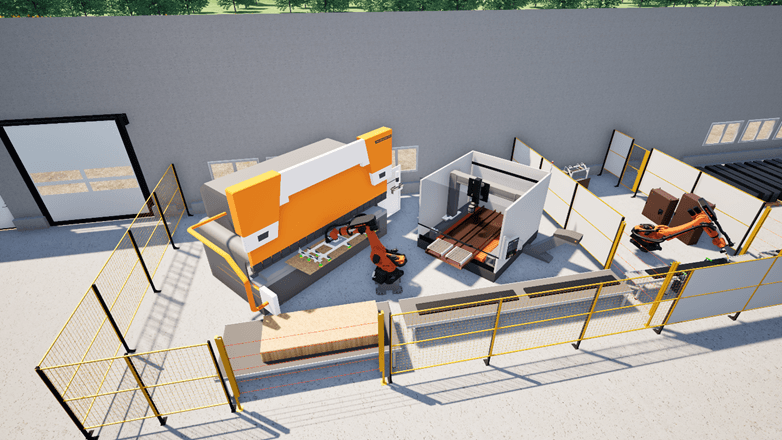

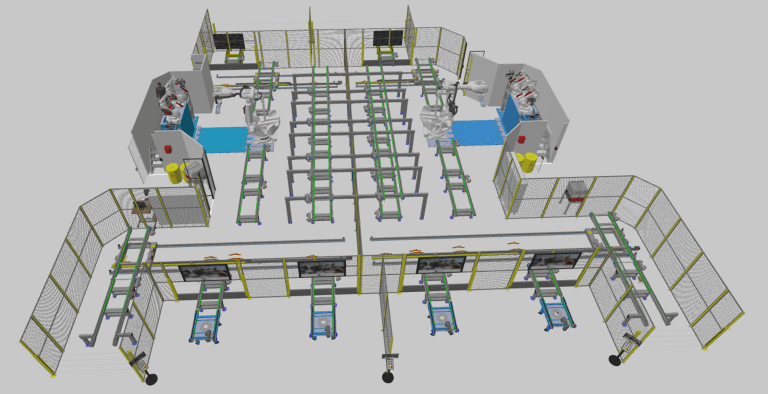

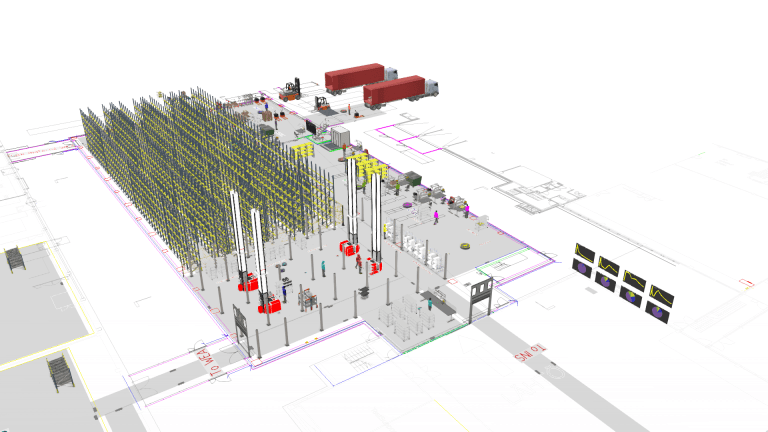

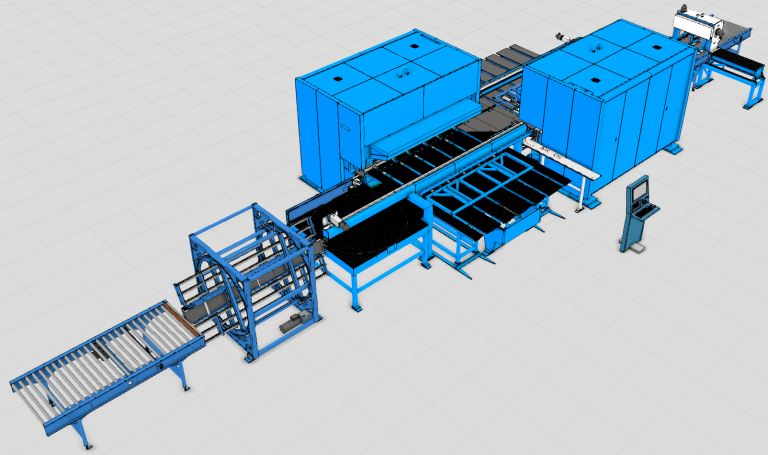

This is where the digital workflow shifts from design to production. Using a custom-built plug-in, Wiksfors brings the .RCD design data into Visual Components to simulate how renovation modules would be manufactured in a real facility. They mapped out everything from layout and reach to takt time, buffer sizing, and shift planning, validating that a 25,000 m² facility with 35 robots and around 100 operators could realistically produce roughly 5,000 apartments per year.

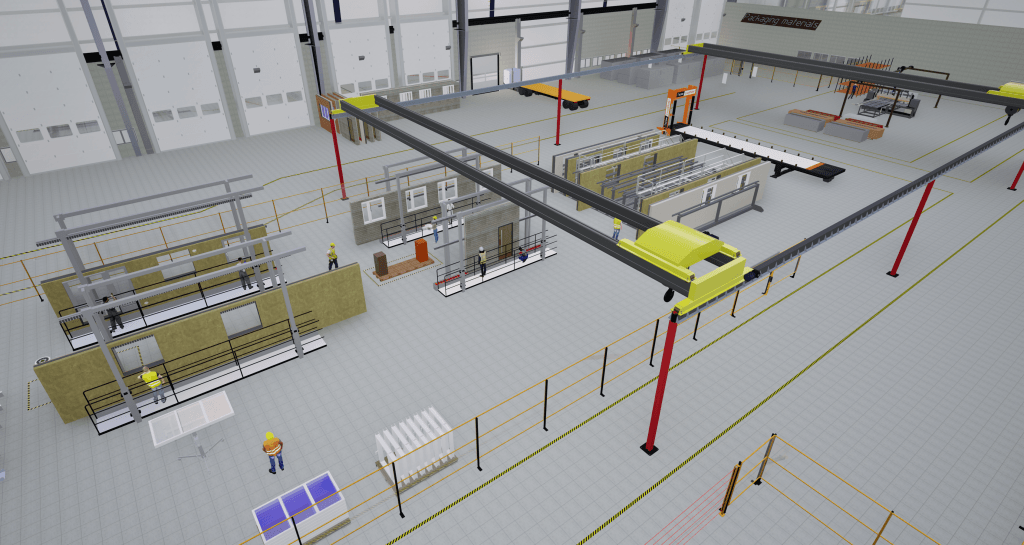

The same dataset is used to simulate RenoChainInstall, the final step of the process. With Visual Components, the team modeled crane access, installation sequencing, safety zones, and on-site logistics to confirm that each renovation could be completed in under three weeks with minimal disruption to residents.

Piloting the process in Säffle

To ground the development in real-world needs, the team partnered with Säfflebostäder, a municipal housing provider, to pilot the workflow on a 1960s-era apartment building in Säffle, Sweden. The building was scanned, modeled, and simulated using the full RenoChain process, from renovation logic in RenoChainBuilder to factory simulation and site planning in Visual Components.

The result was a validated concept that showed potential to cut energy use by over 50%, reduce total renovation costs by 33–50%, and minimize on-site time to just three weeks. All of that was modeled and evaluated before stepping on-site.

Planning smarter, aligning faster

Beyond validating factory flows and installation plans, simulation helped Wiksfors make faster, more confident decisions across the board. Visual Components’ flexible and extensible platform made it particularly well-suited for a project like RenoChain, where a custom plug-in, live production data, and tailored workflows were essential. Its open API allowed Wiksfors to integrate their own .RCD format directly into the simulation environment, while its built-in component library and visual interface made it easy to test layout options, automation strategies, and shift plans before any physical investment was made.

What excites us is not only how accurate the simulations are, but how clear they make the vision. With Visual Components, every stakeholder—from engineers to city planners—can see the same future and work toward it together.

Pontus Wikholm, CEO, Wiksfors Technology

Visual Components also became a powerful communication tool. The same 3D simulations and animations helped align internal teams and external stakeholders. From robotic suppliers and factory planners to installation crews and public housing officials, everyone could visualize the plan and understand how it would work.

That level of shared understanding made a difference. It supported clearer CAPEX planning, reduced the risk of late-stage surprises, and gave stakeholders more confidence in the concept.

A clearer path toward scalable renovation

RenoChain is still in active development, but the direction is clear. By linking building scan data with design logic, production simulation, and installation planning, the team is building a renovation model that’s faster, leaner, and more predictable than traditional approaches.

If you’d like to see how it all comes together, you can watch a short overview video of the entire RenoChain initiative: https://campaign.renochain.se/video-eng/

Visual Components plays a central role in that effort. Its platform not only helps simulate and test complex production and installation flows, it also helps teams communicate, iterate, and align more quickly. And as more partners explore how to scale or adapt the RenoChain model, that flexibility will be just as important as the technical foundation.

For a challenge as big and urgent as upgrading Sweden’s aging housing stock, having that kind of clarity and confidence matters.

About Visual Components

Founded by a team of simulation experts and amassing over 25 years in business, Visual Components is one of the pioneers of the 3D manufacturing simulation industry. The organization is a trusted technology partner to a number of leading brands, offering machine builders, system integrators, and manufacturers a simple, quick, and cost-effective solution to design and simulate production processes and offline robot programming (OLP) technology for fast, accurate, and error-free programming of industrial robots.

Contact us today to explore how our solutions can help your business.

About Wiksfors

Wiksfors Technology is a high-tech innovator rethinking how homes are designed, manufactured, and renovated. With expertise in virtual commissioning, we connect PLC and robot programming directly with simulation models, enabling our clients to validate and optimize production lines before they’re built.

Our data-driven approach turns digital designs into efficient, scalable workflows—delivering high value for line and machine builders who want to take the next step into smart, automated production. Through initiatives like RenoChain, we combine simulation, automation, and sustainable methods to make housing faster, greener, and more affordable.

We invite integrators/machine builders, housebuilders, developers, and architects to collaborate with us in shaping the future of the house industry.

Further reading

MSK Finland advances robot cell automation and intralogistics planning with Visual Components offline programming and manufacturing simulation

MSK Finland increases efficiency in both robot cell automation and intralogistics planning using Visual Components robot offline programming (OLP) and manufacturing simulation software. By creating and validating robot programs virtually,...

Vaisala optimized and validated its new logistics center with Visual Components

Vaisala recently built a new logistics center at its Vantaa headquarters to support growing production needs. Using Visual Components’ 3D simulation platform, the automation team modeled the entire facility to...

Pivatic streamlines sheet metal machine sales, software validation, and line optimization with Visual Components

Designing complete sheet-metal fabrication lines is no small task. Each project brings together machines, motion, and control systems into one smooth, custom-built process. With Visual Components, Pivatic has been able...