Visual Components brings digital twin technology to the classroom at IGTU

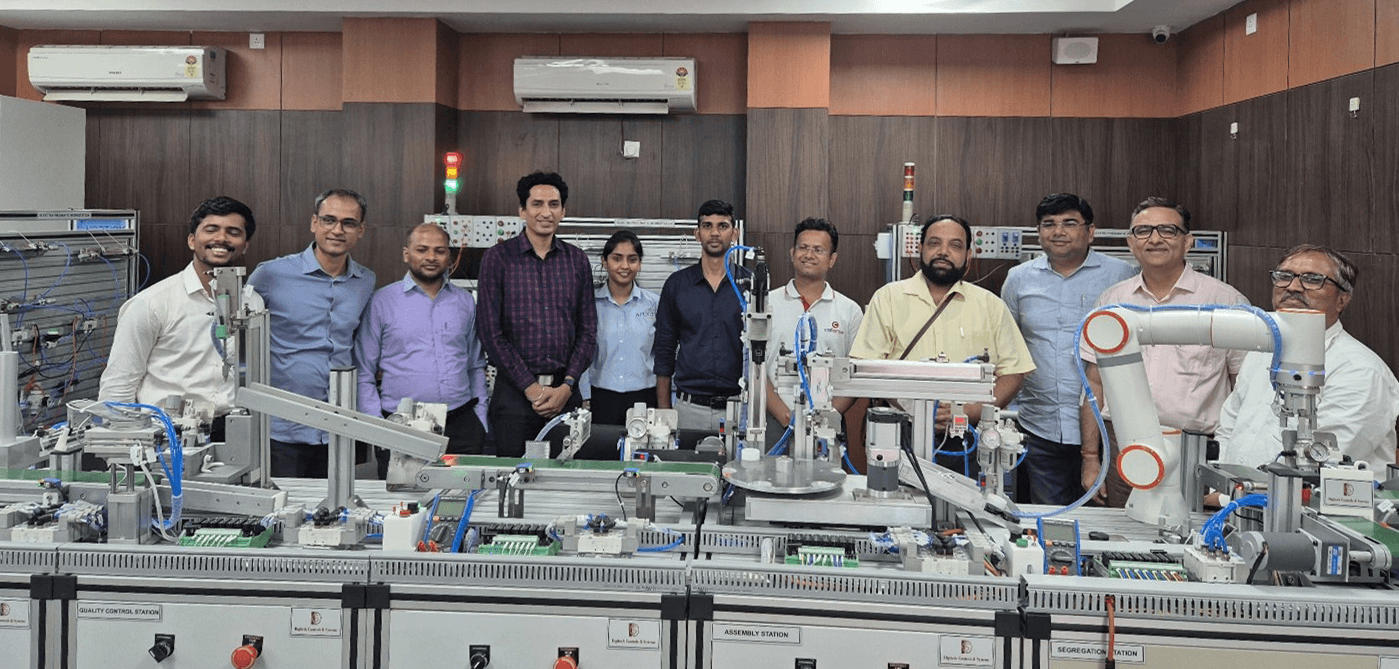

Indira Gandhi Technical University for Women (IGTU), one of India’s leading engineering institutions, is preparing its students for the future of smart manufacturing. With more than 300 women engineers trained annually, IGTU has launched a new simulation lab centred around Visual Components. The initiative gives students hands-on access to factory simulation, robotics, and digital twin concepts, equipping them with the tools they need to thrive in Industry 4.0 careers.

Building a bridge between physical automation and digital simulation

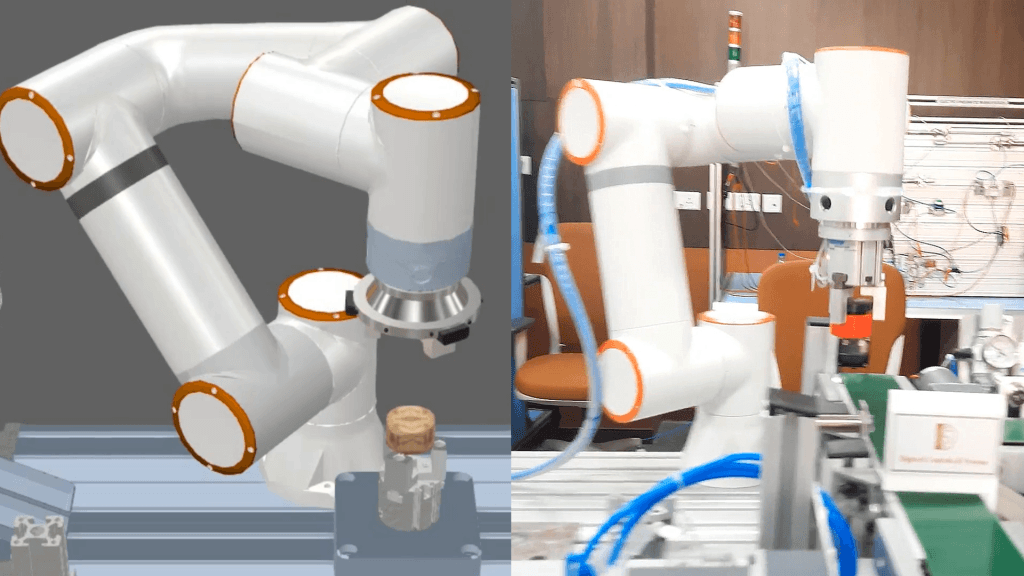

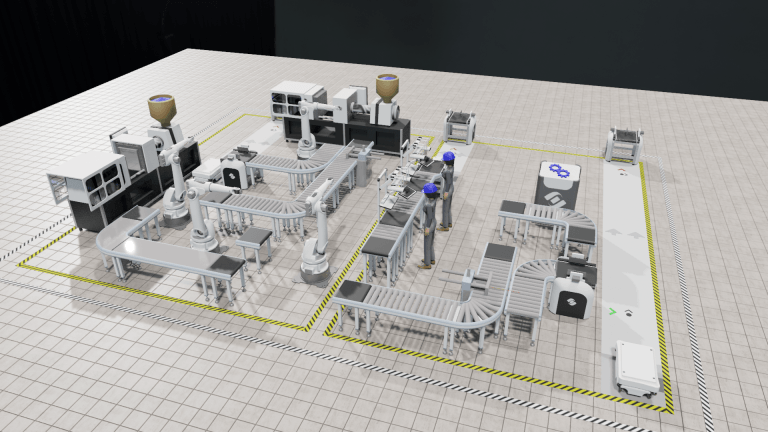

IGTU’s smart manufacturing initiative includes a Computer Integrated Manufacturing (CIM) system, developed and installed by Digitech Robotics India Private Limited. The CIM system features real automation hardware that students can interact with on the lab floor.

To complement that physical setup, IGTU wanted a virtual layer that would:

- Let students simulate and test production workflows before going hands-on

- Reduce bottlenecks around limited access to physical stations

- Introduce the concept of digital twins in a way that aligns with real-world factory tools

“We are using Visual Components software for our mechatronic system to design, simulate, and validate the complete automation process. This software helps us visualize system behavior, verify layouts, optimize cycle time, and ensure smooth integration of mechanical, electrical, and control components before actual implementation. It significantly improves design accuracy, reduces development time, and enhances overall system reliability.”

Mr. Ajit Gate, Director, Digitech Robotics India Private Limited

That’s where Visual Components came in.

With support from APEXIZ, the official Visual Components distributor in India, the university implemented the Visual Components Education Edition and a custom-built simulation model of the Digitech Robotics India Private Limited CIM system. Now, students can explore how production systems work, both physically and virtually, within one connected environment.

Hands-on learning through 3D manufacturing simulation

With Visual Components at the core of the lab, students gain the ability to:

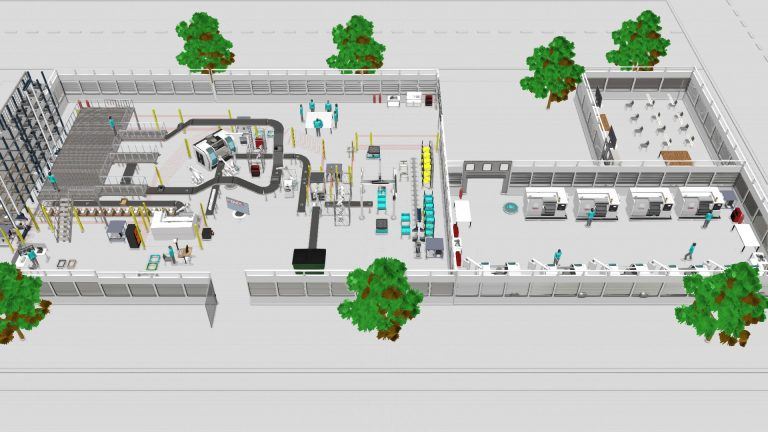

- Simulate material flow, robot arms, and production sequences in 3D

- Build their own layouts using drag-and-drop smart components

- Validate logic and layouts before interacting with hardware

- Learn concepts like virtual commissioning, offline programming, and factory automation in an immersive environment

“Our vision is twofold. First, to use Visual Components to educate students about the wide variety of industrial equipment—through access to over 3,500 smart models in the eCatalog. Second, to empower aspiring manufacturing professionals with hands-on experience in simulation, offline programming, and virtual commissioning—tools essential for smart decision-making in modern factories.”

Hari Nidamarthy, CEO, APEXIZ

Faculty at IGTU have already integrated Visual Components into robotics, production planning, and automation coursework. Students are using the simulation environment not just for assignments, but to prototype start-up concepts inside the university’s incubation center.

Building India’s next generation of smart manufacturing talent

By combining real CIM hardware with virtual modeling in Visual Components, IGTU has created a future-ready learning environment. The setup gives students a more complete understanding of how digital factories work and how simulation tools can play a central role in planning, optimization, and automation.

“We are incredibly proud to be part of the curriculum at IGTU, supporting the technical education of women in India through our software and enabling them to create and implement digital twins, smart manufacturing and robotics through a single package. We very much look forward to the cooperation with IGTU and seeing the results created by their staff and students alike.”

Hans Garritzen, Partner Manager, Visual Components

Project partners

CIM System Design & Integration

Digitech Robotics India Private Limited – Designed the physical automation setup and supported deployment.

Digital Twin Development & Software Enablement

APEXIZ – Delivered the Visual Components Education license, built the CIM simulation model, and enabled faculty training.

About Visual Components

Founded by a team of simulation experts and amassing over 25 years in business, Visual Components is one of the pioneers of the 3D manufacturing simulation industry. The organization is a trusted technology partner to a number of leading brands, offering machine builders, system integrators, and manufacturers a simple, quick, and cost-effective solution to design and simulate production processes and offline robot programming (OLP) technology for fast, accurate, and error-free programming of industrial robots.

Contact us today to explore how our solutions can help your business.

Further reading

International robotics and simulation competition in China, and smart factory project

This case is about a large-scale international competition where hundreds of students participated in designing the digital twin of smart factories using Visual Components-based powerful simulation technology. Read more about...

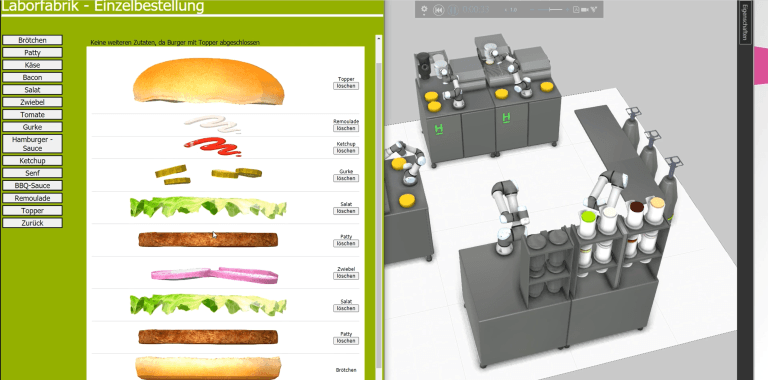

Helping students accurately simulate production environments in real-time

How can simulating an automated restaurant-like environment help students understand the power of simulation?

CU Coventry Case Study: Sparking Students’ Creativity When Designing Real-life Industrial Scenarios

A look at how students in Coventry University's Electro-Mechanical Engineering use Visual Components' 3D simulation software to carry out factory floor simulation.