Pivatic streamlines sheet metal machine sales, software validation, and line optimization with Visual Components

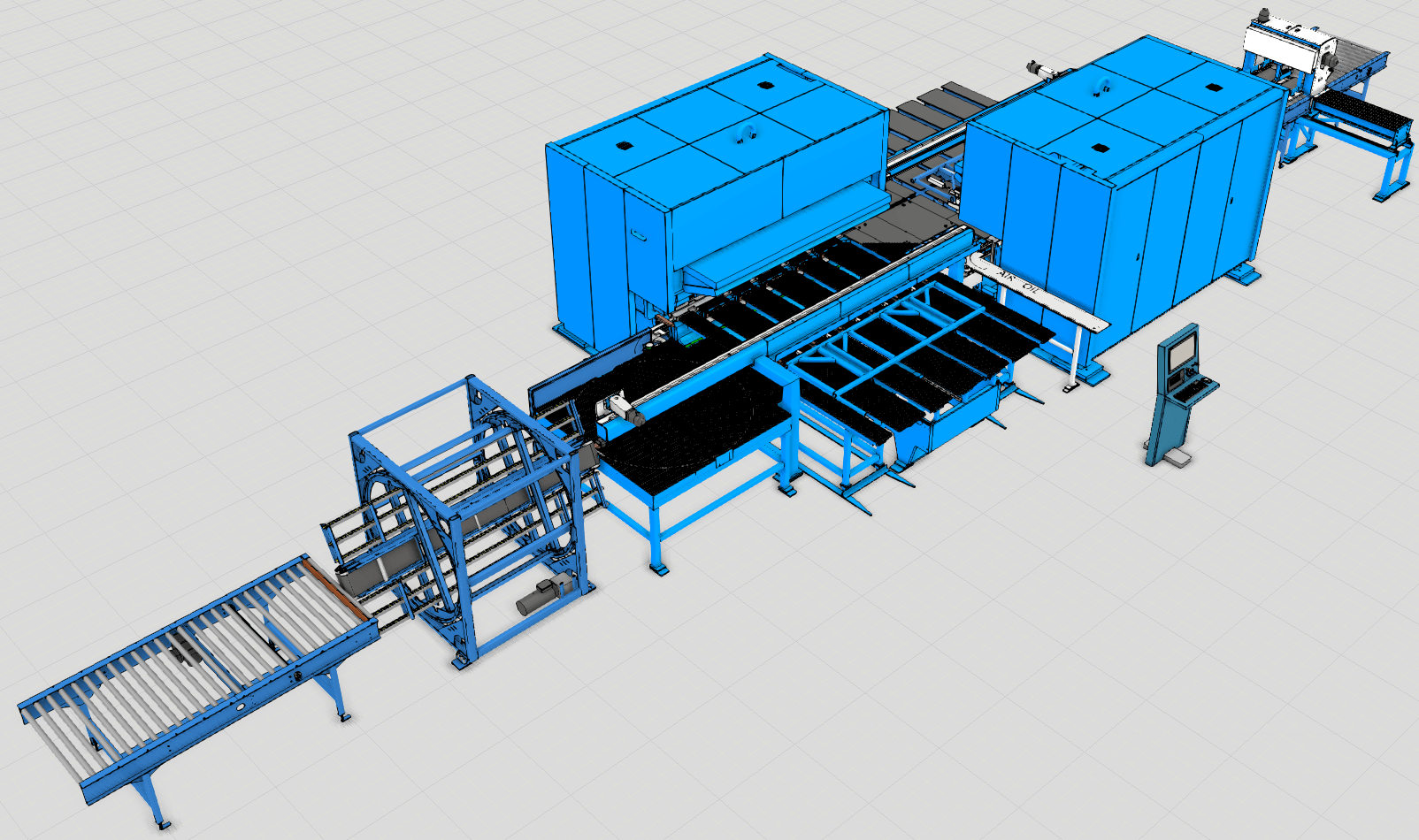

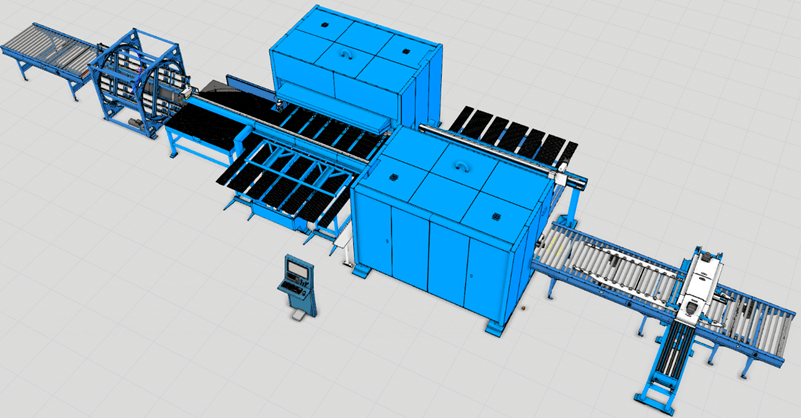

Designing complete sheet-metal fabrication lines is no small task. Each project brings together machines, motion, and control systems into one smooth, custom-built process. With Visual Components, Pivatic has been able to show customers how each line will perform before anything is built, test control logic virtually, and fine-tune performance once it’s up and running.

Engineering smarter sheet metal lines

For nearly 50 years, Pivatic has been designing and delivering automated sheet-metal fabrication machines and lines from its base in Hyvinkää, Finland. Known for its coil-fed and blank-fed systems, the company builds fully integrated solutions for punching, bending, and shearing; exporting most of its production to customers around the world.

As projects became larger and more complex, Pivatic needed a better way to test and present ideas before production. Customers wanted to see how systems would work, engineers wanted to test control logic earlier, and teams needed to make sure each line fit the customer’s facility.

About five years ago, Pivatic started using Visual Components. The 3D manufacturing simulation platform is now central to how they design, validate, and optimize their systems before shipping them off to customers.

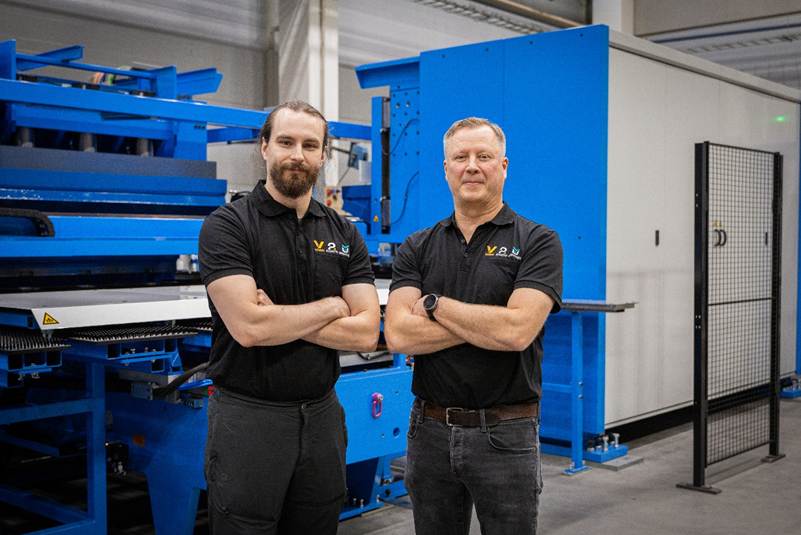

In 2024, Pivatic became part of Vaski Group, a Finnish industrial machinery group specializing in flat bar and sheet metal systems, alongside Vaski and Ursviken. Within the group, Pivatic continues to lead the way in using Visual Components to design and deliver complex production lines.

Today, Pivatic uses Visual Components in three key areas:

- accelerating sales with 3D simulations,

- validating control software with virtual commissioning, and

- optimizing or troubleshooting systems already in production.

Accelerating sales with 3D simulations

Selling a coil-fed punching and bending line is unlike selling a standard machine, it’s a custom system with many moving parts, each tailored to the customer’s process. For many buyers, interpreting CAD drawings or written specifications is difficult, and traditional presentations often left room for misunderstanding.

Using Visual Components’ simulation tools, Pivatic’s sales and engineering teams have been able to build a fully animated 3D simulation of a proposed line. The simulations help demonstrate how material moves through every stage: coils unwinding, sheets feeding into punching stations, parts transferring to bending cells, and finished pieces stacking neatly at the end.

This realistic visualization helps customers grasp the solution immediately.

Many of our customers have very strict cycle time requirements, so it’s important to show them exactly how the material flows through the line and what cycle times to expect. Sometimes our lines are completely custom with no reference installations, so the Visual Components simulation becomes our reference.

Mika Virtanen, Technical Director, Vaski Group

Instead of relying on lengthy explanations, Pivatic can use the simulation as a shared visual language during discussions. Customers can virtually walk through their system, explore how it fits their floor plan, and even see how different product variants would be handled. Questions about throughput or bottlenecks are answered instantly, and design adjustments (changing a conveyor route, or resizing a buffer, for example) can be tested very quickly.

This iterative approach helps both sides reach the best possible solution before any hardware is built.

Validating control software with virtual commissioning

Once a project moves into the engineering phase, Pivatic uses Visual Components to validate machine control software through virtual commissioning. Each Pivatic line runs on sophisticated PLC (Programmable Logic Controller) programs that synchronize punching, bending, material handling, and safety systems.

Previously, this control logic could only be tested after the real machine was built, which meant software bugs or timing issues were often discovered late in the process, causing costly delays. Now, engineers use Visual Components to create a digital model of the machine or full line and connect it directly to the real PLC through an interface such as OPC UA.

In this setup (hardware-in-the-loop testing), the PLC “believes” it’s running the physical system, while the simulation responds like the real equipment would. Engineers can observe how the control logic behaves under realistic conditions, simulating normal operations and edge cases like emergency stops or sensor delays.

“Using simulation, we can test our actual control software and iron out problems before the line is built,” says Virtanen. This has transformed how Pivatic engineers develop and deliver control systems. Logic errors and sequence issues are fixed early, long before commissioning begins.

Before Visual Components, we had to wait for the installation to verify the software on real hardware. That testing was slow. Now we do the software testing before installation is finished, so the software is practically ready. So there is no downtime during commissioning.

Joni Grönholm, Automation Engineer, Pivatic

By the time a machine reaches the customer site, its software has been pre-validated in a risk-free virtual environment. Commissioning becomes faster and smoother, with fewer on-site issues and shorter ramp-up times. Customers notice the difference: the line performs as expected almost immediately after installation.

We’ve been able to speed up commissioning time by 2 to 3 weeks.

Juha Tusa, Automation Engineer, Pivatic

Optimizing and troubleshooting production lines

The advantages of simulation don’t stop once the line is delivered. Pivatic uses Visual Components as a continuous improvement and after sales tool, helping customers maximize system performance throughout its lifecycle.

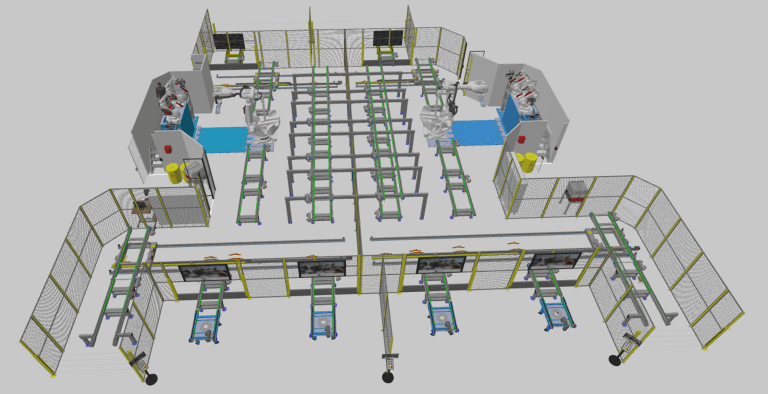

Over time, customers may want to boost throughput, introduce new part types, or eliminate bottlenecks. Instead of experimenting directly on the production floor, Pivatic’s engineers use the digital twin of the line to test improvements virtually. The model mirrors the real system, including updated cycle times, sensor data, and material flow, allowing engineers to run “what-if” analyses safely.

When we have lines on site and the customer wants to speed up the line, we can do similar iterations of the existing line in Visual Components. We might improve 10 or 20 percent of the cycle by improving the software or adding some other things in the line.

Mika Virtanen, Technical Director, Vaski Group

For example, the simulation might reveal that a that a transfer conveyor can be better optimized to improve throughput. The team can explore fixes such as optimizing paths, modifying control sequences, or adding a small buffer.

For customers, this translates into higher uptime, predictable performance, and a data-driven path to improvement.

Group-wide simulation adoption

Pivatic’s success with simulation is now seeing possibilities in the broader Vaski Group.

With more than 200 employees and nearly €50 million in combined revenue, Vaski Group sees simulation as a possible investment for smarter, faster, and more collaborative machine building across its companies.

After over five years of using Visual Components, Pivatic continues to think of possibilities where Visual Components can expand its capabilities, exploring areas like operator training, and more advanced virtual commissioning setups. “We’ve benefited greatly from using Visual Components,” says Virtanen, “and we expect all the companies in Vaski Group to gain similar advantages in these three key topics”.

“We can expand this knowledge to the rest of Vaski Group,” adds Joni Grönholm, Automation Engineer at Pivatic. “So that everyone benefits the same way we have.”

About Visual Components

Founded by a team of simulation experts and amassing over 25 years in business, Visual Components is one of the pioneers of the 3D manufacturing simulation industry. The organization is a trusted technology partner to a number of leading brands, offering machine builders, system integrators, and manufacturers a simple, quick, and cost-effective solution to design and simulate production processes and offline robot programming (OLP) technology for fast, accurate, and error-free programming of industrial robots.

Contact us today to explore how our solutions can help your business.

About Vaski Group

Vaski Group is a fast-growing industrial machinery company specializing in flat bar and sheet metal systems through three brands: Vaski, Pivatic, and Ursviken. The group serves energy, electrical, and data center markets with advanced automation and metalworking solutions. With nearly €50 million in annual revenue and over 200 professionals, Vaski Group combines strong industrial roots with a commitment to innovation and sustainable growth.

Further reading

MSK Finland advances robot cell automation and intralogistics planning with Visual Components offline programming and manufacturing simulation

MSK Finland increases efficiency in both robot cell automation and intralogistics planning using Visual Components robot offline programming (OLP) and manufacturing simulation software. By creating and validating robot programs virtually,...

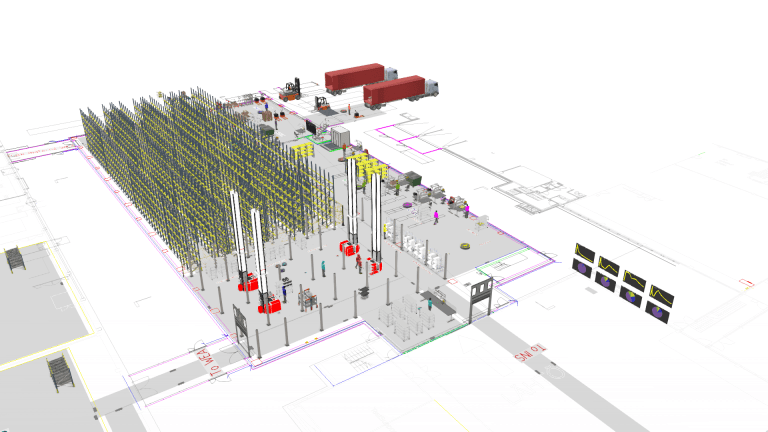

Vaisala optimized and validated its new logistics center with Visual Components

Vaisala recently built a new logistics center at its Vantaa headquarters to support growing production needs. Using Visual Components’ 3D simulation platform, the automation team modeled the entire facility to...

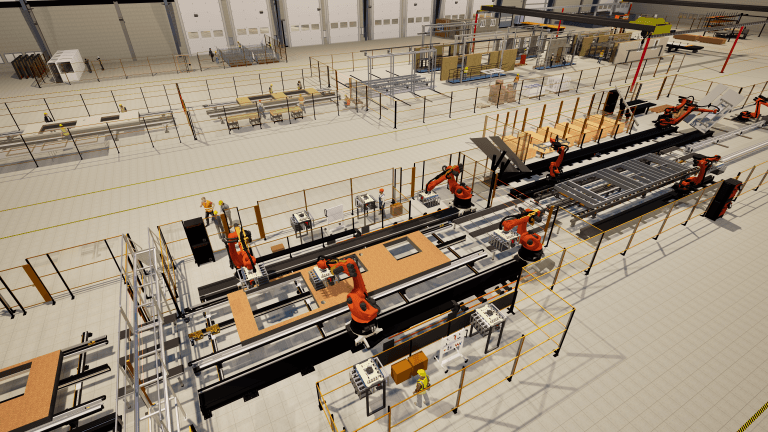

Wiksfors uses Visual Components to bring renovation into the factory era with RenoChain

Modernizing Sweden’s aging housing stock calls for a smarter approach. With Visual Components, Wiksfors developed RenoChain, a factory-based renovation concept that uses simulation to plan and prove a faster, more...