CNC-ing clearly now: boosting proposal speed and client understanding with Visual Components at Mazak UK

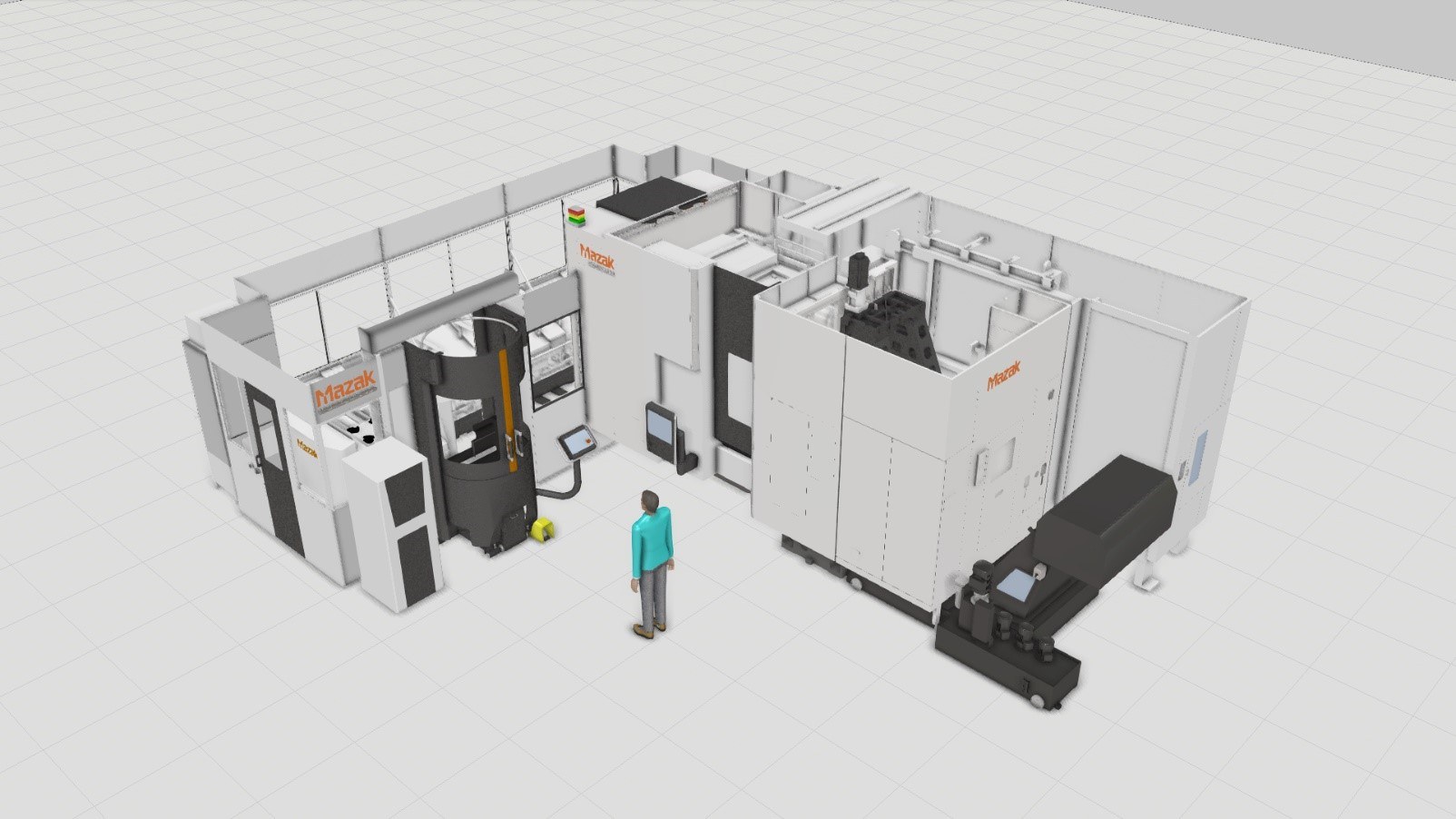

Mazak UK, part of a global leader in CNC machine tools manufacturing, faced significant operational challenges, particularly in conveying the complexities of their Palletech system using traditional 2D drawings. This hindered clear client communication and elongated proposal times. The adoption of Visual Components marked a turning point by helping Mazak UK significantly cut down project planning and execution time, ushering in a new era of efficiency and improved client engagement.

Accelerating proposal generation with Visual Components

Mazak UK’s Project Engineering Centre in Worcester, England, faced several challenges in their quest for operational excellence. One significant hurdle was the complexity of explaining and planning around their Palletech system, a highly advanced, modular flexible manufacturing system designed to optimize the efficiency of Mazak’s CNC machine tools. This system is characterized by its modularity, allowing for customization according to specific manufacturing needs. It can include multiple machines, robotic arms for material handling, and storage solutions, all working in unison to streamline production.

However, the complexity of the Palletech system lies in its extensive customization options and the intricate interplay of its components. This complexity posed a significant challenge for the team at Mazak UK, as traditional 2D drawings and explanations were insufficient to convey the full capabilities and configurations of the system. The detailed nature of the system, with its numerous components and possible configurations, made it difficult for clients to fully grasp the extent of its functionality and efficiency without a more dynamic and interactive representation.

The search for a solution led Mazak UK to Visual Components, promising not just an upgrade in how they presented their solutions to clients, but also a restructuring of their internal processes, particularly in CNC machine programming and CAD/CAM integration. The decision to implement Visual Components was driven by its compatibility with Mazak’s existing infrastructure and its potential to significantly cut down on the time and resources spent on project planning and execution.

With Visual Components, Mazak UK achieved a remarkable improvement in the speed and efficiency of their proposal generation. Where it once took weeks to prepare and present a proposal to clients, Visual Components enabled the team to accomplish this in a fraction of the time.

Previously, we were looking at around about 4 days to turn a proposal around, and currently (with the help of Visual Components) we can probably fire one out in about half an hour.

Stephen Smith, Project Manager at Mazak UK

Client engagement and understanding with 3D visualization

The 3D visualization capabilities of Visual Components marked a paradigm shift in how Mazak UK engaged with its clients. From high quality video and images to 3D PDFs, the software’s ability to present complex manufacturing systems in an easily digestible 3D format meant that clients could better understand the proposed solutions.

The introduction of Visual Components at Mazak UK’s Project Engineering Centre enabled the engineers to adopt a more client-centric approach. This approach, focusing on involving the client in the design process, led to improved client relationships and satisfaction. Additionally, the integration of Visual Components into Mazak’s workflow enhanced operational efficiency not only on the manufacturing floor but also in sales, project management, and client servicing. The software allowed for a more integrated approach to project management, connecting different aspects of the operation.

Customization for enhanced project delivery

One of the standout features of Visual Components that Mazak UK capitalized on is its robust customization capabilities. This aspect of the software played a crucial role in enhancing their manufacturing process optimization. The ability to tailor each component and simulation to meet specific project requirements offered Mazak a significant edge in both design and execution.

Key aspects of customization include:

- Modifying 3D models: Engineers at Mazak UK were able to alter and fine-tune 3D models within Visual Components, ensuring each component accurately represented their real-world counterparts.

- Scripting for advanced functionality: Utilizing the open API and Python scripting in Visual Components, Mazak added custom functionalities to their models. This approach allowed them to simulate complex manufacturing scenarios and machine interactions that were previously challenging to conceptualize.

Stephen Smith, Project Manager at Mazak UK, explains, ‘Given that everything can have a Python script behind it, we’re able to attach interfaces to these modules, and we’re able to make sure that they clip together, first of all, in the right place. Or secondly, if they can’t clip together physically, they won’t in the software world.” This level of detail in scripting enhances the precision and reliability of the simulations.

In addition, Mazak has created an automated solution that creates a bill of materials from the layout with one click of a button, further speeding up the proposal process. - Adapting to client specifications: Customization also extended to adapting designs based on specific client requirements. By tweaking models and simulations, Mazak could present tailored solutions that resonated more effectively with their clients.

To further enhance planning and operational efficiency, Mazak UK incorporated statistical analysis from Visual Components which can be displayed visually in software as pie charts and line graphs. Statistical reports can be generated to assist in planning, to check on things like ensuring that manually loaded cells are optimized so that the operator is not overworked, for example, and the machines are not left idle. In some instances, this has allowed for planning of how operators carry out other duties without affecting the output of the cell, showcasing to clients a flexible and efficient use of human resources.

Mazak UK’s adoption of 3D simulations in their customer communications serves as a compelling case of how digital transformation can propel a manufacturing company to new heights. The efficiency gains, enhanced client engagement, and operational improvements exemplify the potential of embracing simulation tools like Visual Components.

About Visual Components

Founded by a team of simulation experts and amassing over 20 years in business, Visual Components is one of the pioneers of the 3D manufacturing simulation industry. The organization is a trusted technology partner to a number of leading brands, offering machine builders, system integrators, and manufacturers a simple, quick, and cost-effective solution to design and simulate production processes and offline robot programming (OLP) technology for fast, accurate, and error-free programming of industrial robots.

Want to learn more about the benefits of our solutions for your business? Contact us today!

Further reading

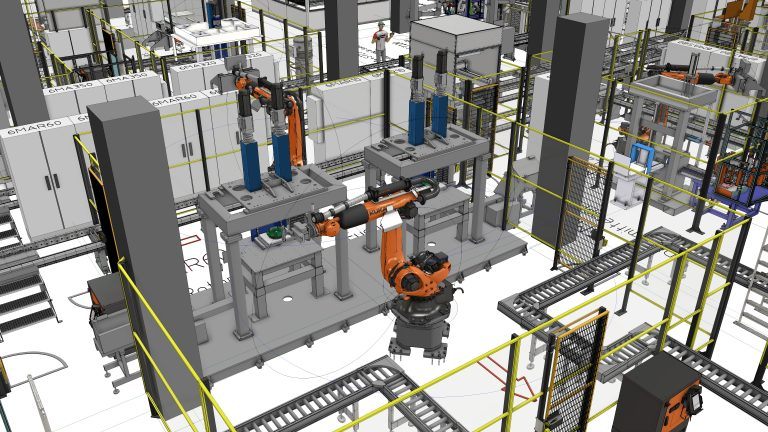

Elevating assembly planning for elevator button panels at KONE with 3D simulation

Planning a new assembly line for two product variants, KONE’s Northern Italy site needed to ensure smooth flow and minimal risk of defects. With Visual Components, they simulated and tested...

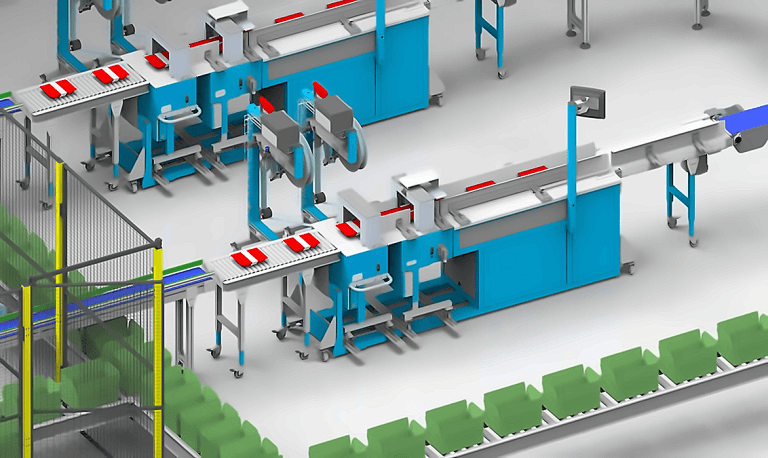

How Hollander Techniek designed an automated custom meal packaging system with Visual Components

When Uitgekookt set out to automate its meal packaging process, they needed a system that could handle custom orders with speed and precision. Hollander Techniek used Visual Components to design...

How EMIL SCHMID MASCHINENBAU designed a high-speed battery assembly plant with Visual Components

Facing the challenge of designing a fully automated battery assembly plant for a customer, EMIL SCHMID MASCHINENBAU turned to Visual Components. With 3D simulation and an extensive library of factory...