Products

Visual Components 5.0.

Coming early 2026.

From concept to reality.

On a more powerful platform.

All-in-one manufacturing simulation. More capable than ever.

Visual Components 5.0 is on the way and it will still be the fastest way from concept to reality, with better performance, more customization options and expanded support for virtual commissioning.

Whether you’re building layouts, defining process flows or validating production lines, Visual Components 5.0 will help you get more done, faster and with greater flexibility.

Fast and easy robot programming. Even more automated.

Visual Components 5.0 brings robot offline programming (OLP) automation to its most advanced level yet, empowering manufacturers to fully leverage model-based engineering.

With support for model-based definition (MBD) and product manufacturing information (PMI), it enables collaboration from the earliest stages of production planning across industrial processes.

Smarter simulation

Many simulation tools fall short when it comes to the real needs of modern production planning. Limited customization, slow performance and disconnected workflows with multiple tools can slow down decisions and delay projects.

Visual Components 5.0 tackles these challenges head-on. It runs faster, gives you more control over how your simulations work and includes better tools for testing and connecting to real systems, all on a single, unified platform that brings clarity and confidence to every step of your digital production planning journey.

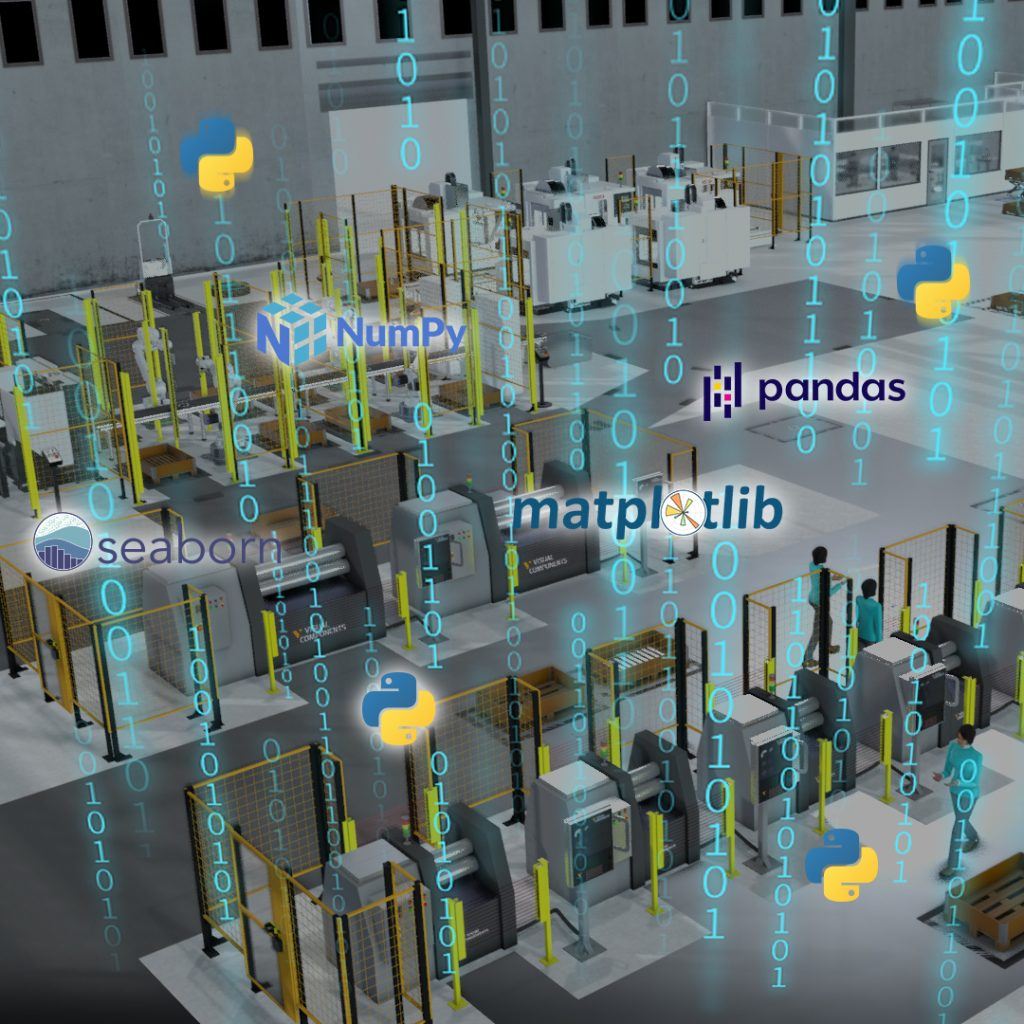

Python 3 API

More control with modern scripting

Many manufacturing simulation tools have fixed features and limited flexibility, making it difficult to adapt them to specific workflows. Visual Components 5.0 takes a different approach.

With a modernized API, full Python 3 support, and improved performance, it gives developers and engineers the tools to tailor their simulation environments, automate tasks, and integrate external tools more easily than ever before.

Gain control and flexibility in shaping your digital factory:

Customize your simulation environment and build extensions with ease

Automate repetitive tasks through custom scripting

Add smart logic and advanced data handling with popular libraries like NumPy and pandas

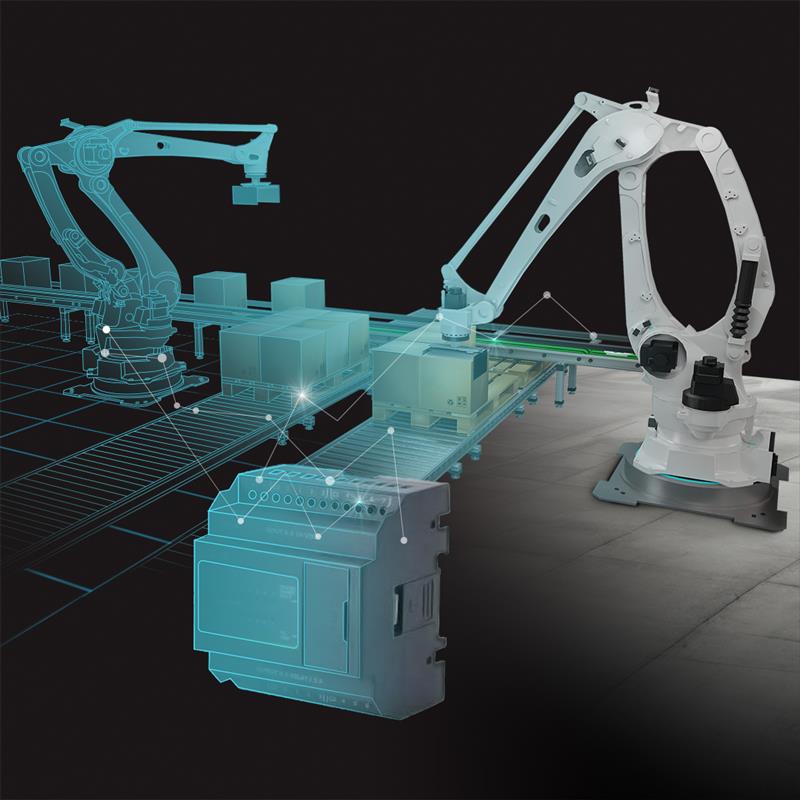

Connectivity plugins

Broader connectivity for smarter integration

Integrating simulations with real-world systems can be complex and fragmented, especially when working across diverse hardware, protocols and automation platforms. This often limits the ability to validate and refine processes virtually before deployment.

Visual Components 5.0 expands connectivity with new robot connectors for Denso, Yamaha, Techman, and Mitsubishi MELFA, plus PLC integration for LS Electric. It also introduces MQTT support, extending compatibility with industrial communication protocols and enabling real-time data exchange during simulation.

Bridge the virtual with more physical systems:

Connect to more real-world equipment with new robot, PLC and MQTT connectors

Validate, test and refine processes virtually with greater confidence and realism

Accelerate deployment by streamlining the handoff from simulation to execution

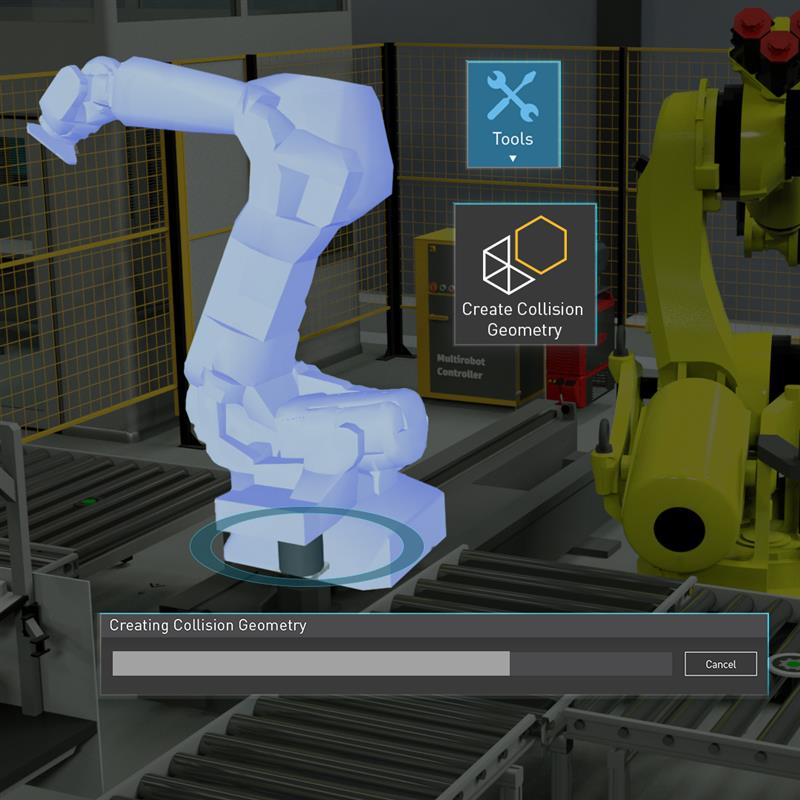

Colliders

Smarter collision geometry for faster simulation

Running simulations with detailed, high-polygon models can slow down collision detection and reduce overall performance, especially in complex layouts with multiple moving components.

The new colliders feature simplifies collision geometry by reducing triangle count by up to 99% in seconds. With full control over collision shape customization, visibility and quality, you can tailor your simulation setup for maximum efficiency.

Speed up simulation with simplified collision geometry:

Reduce computational load for smoother performance

Accelerate collision detection and iteration cycles

Optimize workflows in complex robotic environments

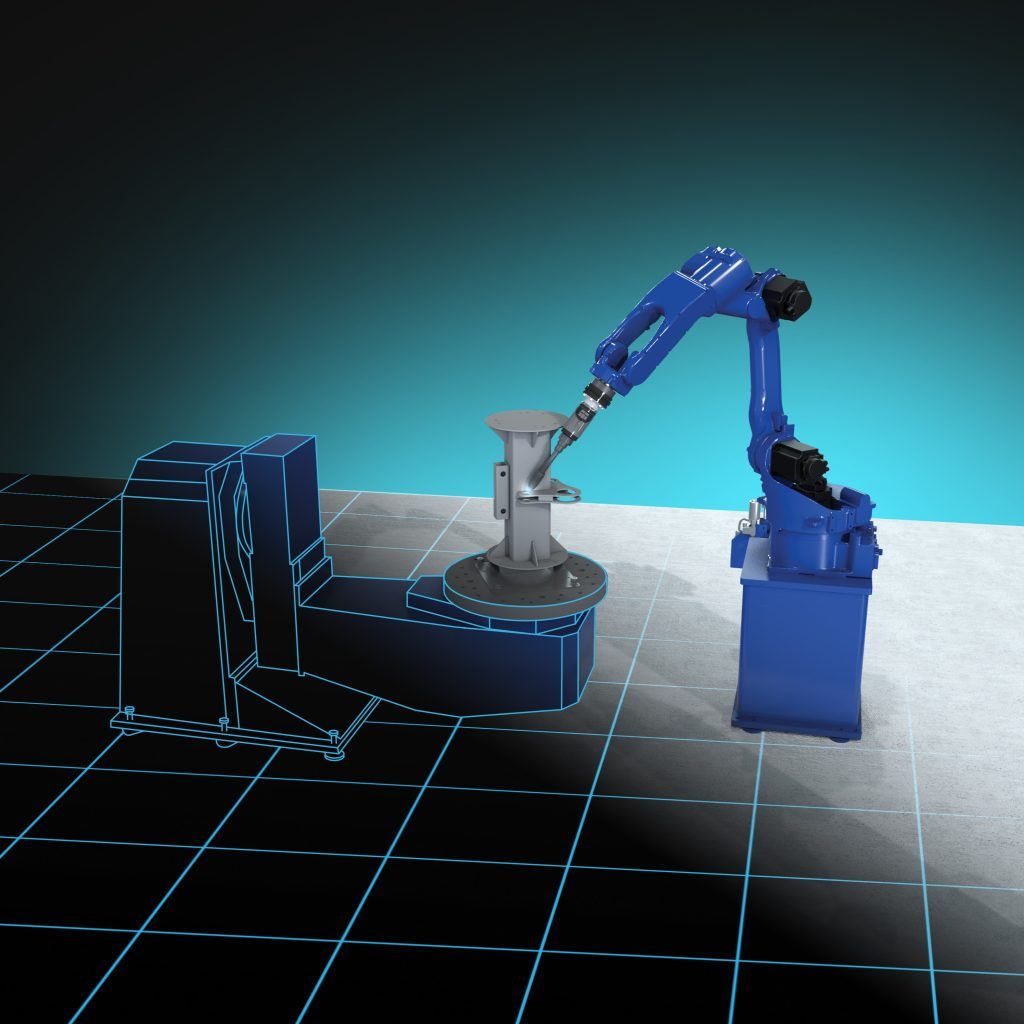

Next level OLP automation

Traditional robot programming often involves disconnected tools, manual processes and brand-specific limitations—slowing down production start and making it harder to scale automation across diverse production environments.

Visual Components OLP 5.0 redefines robot programming with model-based precision and seamless design-to-manufacturing collaboration across industrial processes. It introduces automated robot toolpath generation using PMI and extends multi-brand compatibility—all within a unified environment.

This new approach empowers teams to automate robot programming with greater accuracy, consistency and flexibility. By reducing manual effort, it accelerates deployment timelines and supports scalable, future-ready automation strategies.

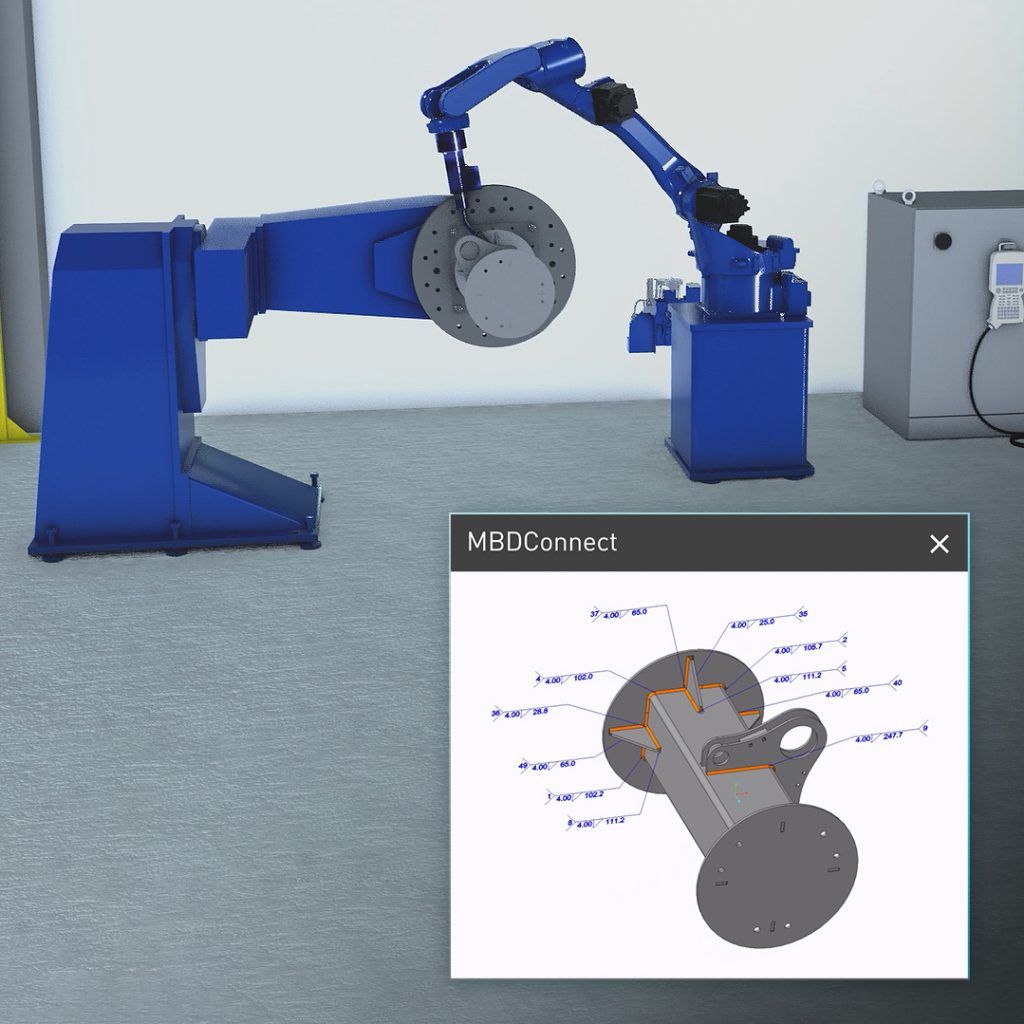

Model-based engineering

Improved design-

to-manufacturing workflow

Translating design intent into executable robot programs often requires manual interpretation of CAD data, which introduces delays and risks of miscommunication—especially in complex manufacturing environments where precision and speed are critical.

Model-based engineering (MBE) automates this process by extracting product manufacturing information (PMI) directly from supported CAD files. This includes dimensions, tolerances, surface finishes and other annotations used to generate robot toolpaths automatically.

Accelerate design-to-production with precision:

Eliminate interpretation errors across teams

Avoid rework and delays with consistent, repeatable workflows

Improve quality and efficiency with automated programming

Automated programming

Faster, scalable robot programming

Programming robots across multiple brands often requires manual adjustments, brand-specific tools and repetitive setup—slowing down deployment and increasing the risk of inconsistencies in quality and performance.

Visual Components OLP 5.0 streamlines this process with built-in post-processors, extending support to 22 robot brands. It automates robotic welding parameters application and robot path solving to avoid collisions. The new Fronius welding power source connector further simplifies weld job management.

Scale robot programming with speed and consistency:

Reduce setup time and manual workload

Ensure consistent quality across operations

Speed up deployment across multiple robot brands

Coming soon

Visual Components 5.0 is just around the corner, packed with updates to make every part of your production planning workflow faster and easier.

Join the waitlist to be the first to get the release email when it goes live in early 2026.