Plan for What’s Next! Three Ways Manufacturers can benefit from the use of 3D Production Simulation in the COVID-19 era

With factories around the globe being idled and many of us now working from home, the COVID-19 pandemic has had a swift and severe impact on the world we live in. While these are certainly challenging times, it’s also an opportunity for us to improve and plan for what’s next.

With factories around the globe being idled and many of us now working from home, the COVID-19 pandemic has had a swift and severe impact on the world we live in. While these are certainly challenging times, it’s also an opportunity for us to improve and plan for what’s next. Here are a few ways 3D manufacturing simulation can help you in these times.

#1: Plan for the expected and unexpected

Short-cycle manufacturers have been hard hit by this crisis, especially those without resilient supply chains. When China, “The World’s Factory” shut down for more than six weeks, many western manufacturers scrambled to find replacement suppliers in other parts of the world. This can be difficult even under normal circumstances, but becomes exponentially more challenging in a panic situation when you’re competing with everyone else at the same time.

Manufacturers can use this time to evaluate their production and supply chain strategies. Today, more manufacturers are seeing the importance of building flexibility and redundancy in their production. And, while this usually comes at a price, so does not being prepared for disruptions like the one we’re currently experiencing. 3D manufacturing simulation allows engineers and planners to evaluate their production strategies against different scenarios, helping them to better understand potential issues and the risks and costs involved.

#2: Virtually communicate production changes

With many of us now working from home and global travel restrictions making it almost impossible to travel these days, virtual meetings and e-mail/messaging are the only ways we can communicate with each other. This presents its own set of challenges for many organizations, especially when it comes to discussing changes on the factory floor. It would be a lot easier to visit the site!

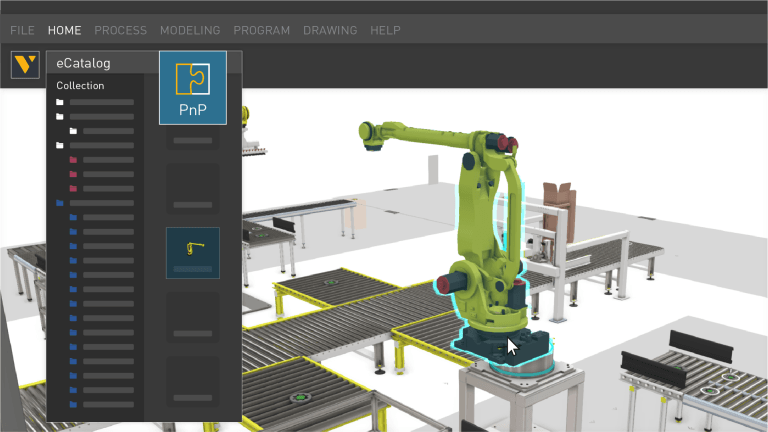

While you and your colleagues may not be able to visit the factory floor, a virtual model is the next best thing. Simulation models created with 3D manufacturing simulation software provide a technically accurate and visual representation of the project, allowing your colleagues to visualize and more easily understand what’s being proposed.

#3: Plan for what’s next

Manufacturers that are still operational are being required to implement social distancing measures on the shop floor, and it’s expected that this will continue for some time as more plants come back online. Implementation of these measures is easier for some than others. Large facilities with fewer workers may be able to continue operations with minimal impact, whereas it could be very challenging for smaller facilities with many workers. The current situation has strengthened the argument for automation in production, and many manufacturers are using this down-time to ramp-up their automation plans.

So, whether you want to explore automating your production, or evaluate how to best implement social distancing measures in your facility while ensuring worker safety and minimal impact to operations, use this down time to design, simulate, and validate your plan.

If you’d like to learn more about how 3D manufacturing simulation can help you plan for what’s next, check out one of our webinars on the topic, or connect with one of our sales representatives.

Further reading

Leveraging simulation for factory layout design

Explore how discrete event simulation and digital twin technology play crucial roles during the ideation and planning phases of factory layout design. Our software simplifies the design process, providing accurate...

Robot offline programming (OLP): the complete guide (with examples)

This is your complete and comprehensive guide to offline robot programming (OLP). After introducing the topic, it addresses common misconceptions, the problems it resolves, benefits, and real-life example of its...

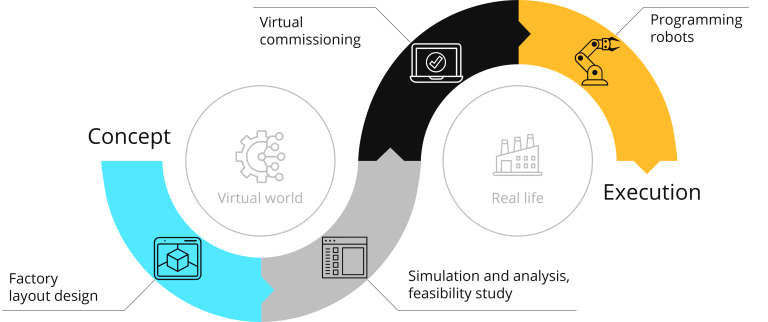

Manufacturing simulation: bring your projects from concept to reality

Manufacturers that commit to the digital transformation inherent in Industry 4.0 will reap the rewards of higher production efficiencies and faster project execution. Together, these will drive growth and profitability...