Industry solutions

Heavy machinery

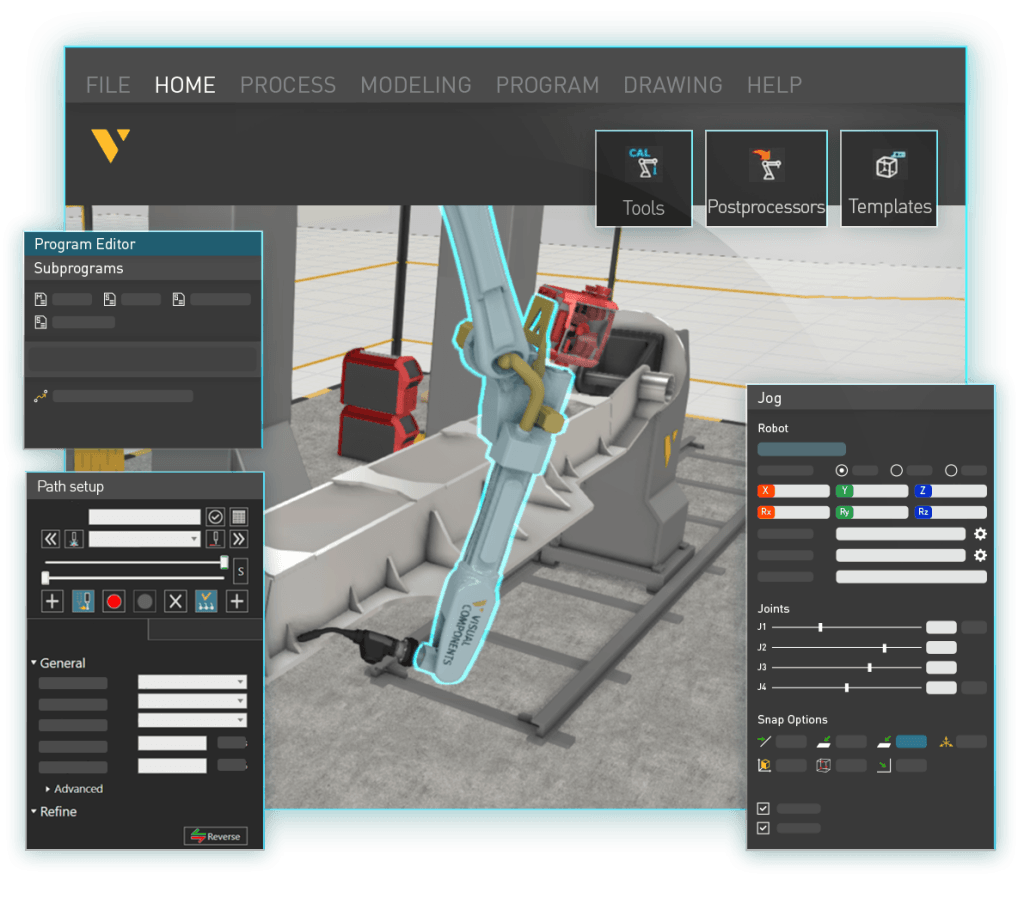

Simulate production and program industrial robots offline to improve your response to downtime and increase your production efficiency.

Why Visual Components?

Improve responsiveness to downtime

Any minor failure or a delay in heavy industry manufacturing processes results in a spike in production costs. You become more responsive to such scenarios with the use of Visual Components 3D simulation.

Be more adaptive and competitive

To stay competitive, you need to improve your process cycle times. Visual components manufacturing simulation helps by testing various scenarios in a risk-free environment and highlight the most optimal process implementations.

Faster robot investment payback

Program robots 10 times faster without stopping production. Ensure fast robot ramp-up time and minimal downtime. Save and re-use your programs for future projects to enhance efficiency and productivity.

Improves production efficiency

Optimize robot movements and production layouts virtually to ensure consistent, high-quality output. Validate designs, fixtures and tooling early to eliminate last-minute changes and keep production running at peak efficiency with minimal downtime.

Key production and automation challenges in heavy machinery manufacturing

Heavy machinery manufacturing overview: processes, products and production complexity

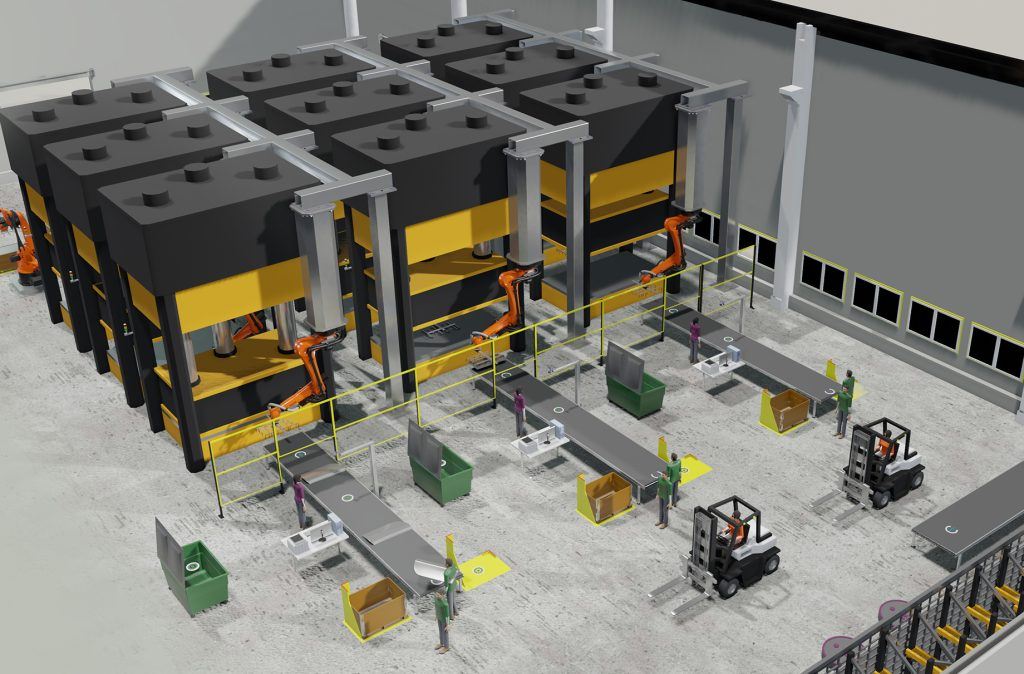

The heavy machinery or “yellow goods” industry includes manufacturers that produce large, welded structures and equipment for construction, energy, marine and offshore applications. Typical products include construction equipment, power generation components such as boiler pipes and membrane walls, shipbuilding structures like panel lines and T-beams and offshore equipment such as pressure vessels and tanks.

These sectors are characterized by large and heavy weldments, high product variability and low- to medium-volume production. Many products are engineered-to-order and depend on robotic welding and precise production planning.

To manage this complexity, manufacturers increasingly use manufacturing simulation and robot offline programming (OLP) to plan layouts, validate robotic welding processes and test programs digitally before commissioning. This helps reduce downtime, improve consistency and support efficient high-mix production.

Core challenges facing heavy machinery and yellow goods manufacturers

Manufacturers in the heavy machinery and yellow goods sector operate in a highly complex environment shaped by stricter environmental regulations, evolving safety standards and growing pressure to improve productivity. At the same time, they must manage skilled labor shortages and increasing product complexity while scaling the use of robotics and automation.

Skilled labor shortage and knowledge gaps

A shortage of experienced welders and robot programmers makes it difficult to maintain throughput and consistent quality. Much of the production knowledge remains personnel-dependent, leading to variability and longer ramp-up times for new products.

High product mix and ramp-up pressure

Heavy equipment manufacturing is often high-mix, low-volume (HMLV). Frequent product changes, engineered-to-order designs and late CAD updates such as added welds increase programming effort and slow down production ramp-up.

Quality inconsistency in complex welding

Large and heavy parts with many repetitive welds, multipass welding, complex seam shapes and difficult reachability create a high risk of variation. Maintaining repeatable quality across different operators and shifts is a constant challenge.

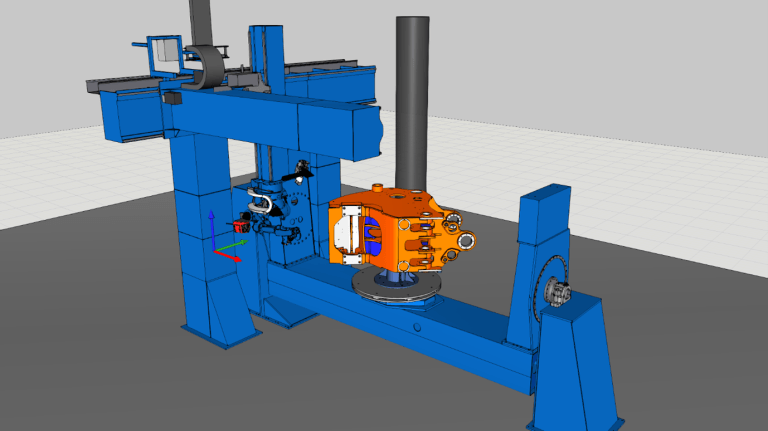

Fixture and design-for-manufacturing challenges

Designing fixtures for big weldments is time-consuming and costly. Late design changes can require rework of tooling and layouts. Increasing modularity in product designs, as well as the adoption of PMI and model-based engineering, adds another layer of coordination between design and production.

Low robot utilization in high-mix low-volume production

Although robotics adoption is increasing across welding and downstream processes, many manufacturers struggle with low robot utilization. Manual, teach-pendant programming is slow and ties up production equipment, limiting the benefits of automation.

Fragmented robot software ecosystems

A mix of robot brands in the same facility often means multiple proprietary programming environments. Generic offline programming tools are frequently sold by process, and post-processors add cost and complexity, making standardization difficult in modular production setups.

Integrating multiple technologies

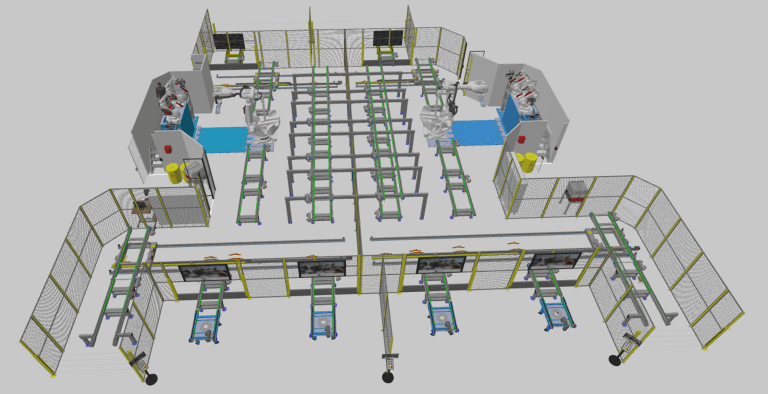

Modern production cells combine robotics, positioners, fixtures, and inspection systems. Coordinating these technologies and validating workflows before commissioning is challenging without digital simulation.

Limits of automatic weld detection

Automatic weld detection works well for simple parts but is less reliable for the large, complex geometries common in yellow goods manufacturing. Engineers still need flexible tools to define and optimize weld paths accurately.

Together, these production and automation challenges drive the need for better digital tools to plan, simulate and optimize manufacturing in heavy machinery industry.

Visual Components use cases in heavy machinery industry

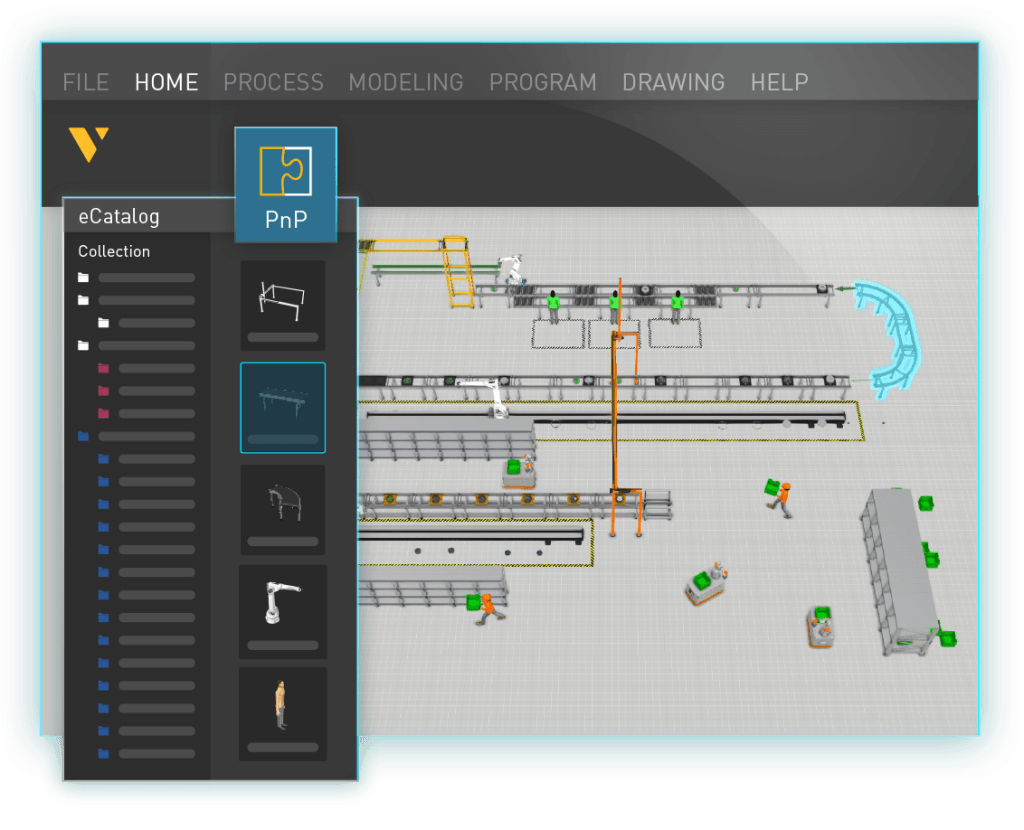

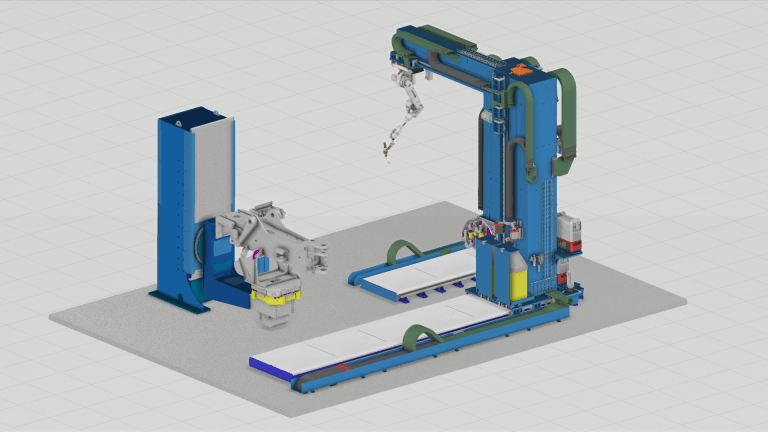

Plan and validate robot cells, conveyor systems and material flow digitally before physical commissioning. Simulation ensures robots, positioners and intralogistics work seamlessly, reducing errors and setup time.

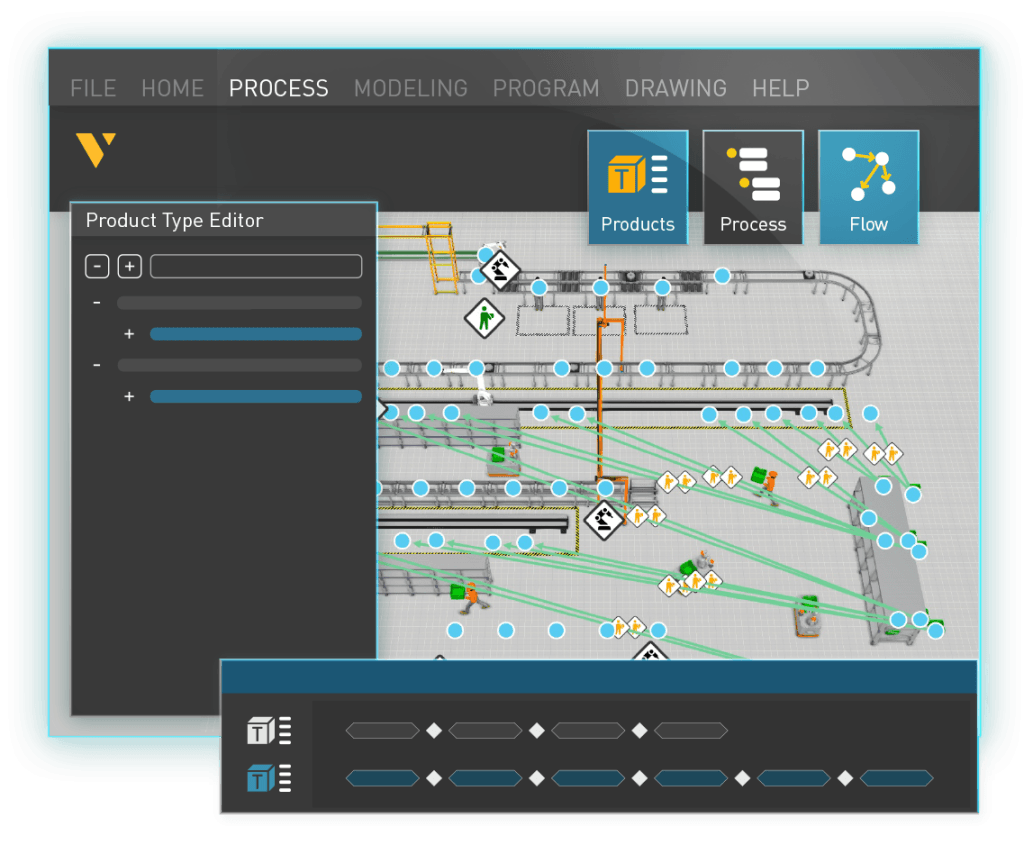

Create and test welding and assembly paths offline to cut programming time by more than half compared with manual teach-pendant programming. This enables faster ramp-up of new production lines and reduces downtime.

Simulate multi-pass welding, complex seam geometries and large weldments to ensure consistent, high-quality results across product variants. Virtual validation minimizes trial-and-error on the shop floor.

Pre-program robots and validate processes in a digital environment to ensure production readiness from day one. This shortens commissioning time and reduces initial production errors.

Use simulation to evaluate production layouts, identify bottlenecks, test “what-if” scenarios and optimize cycle times. This helps manufacturers improve throughput, resource utilization and responsiveness to disruptions.

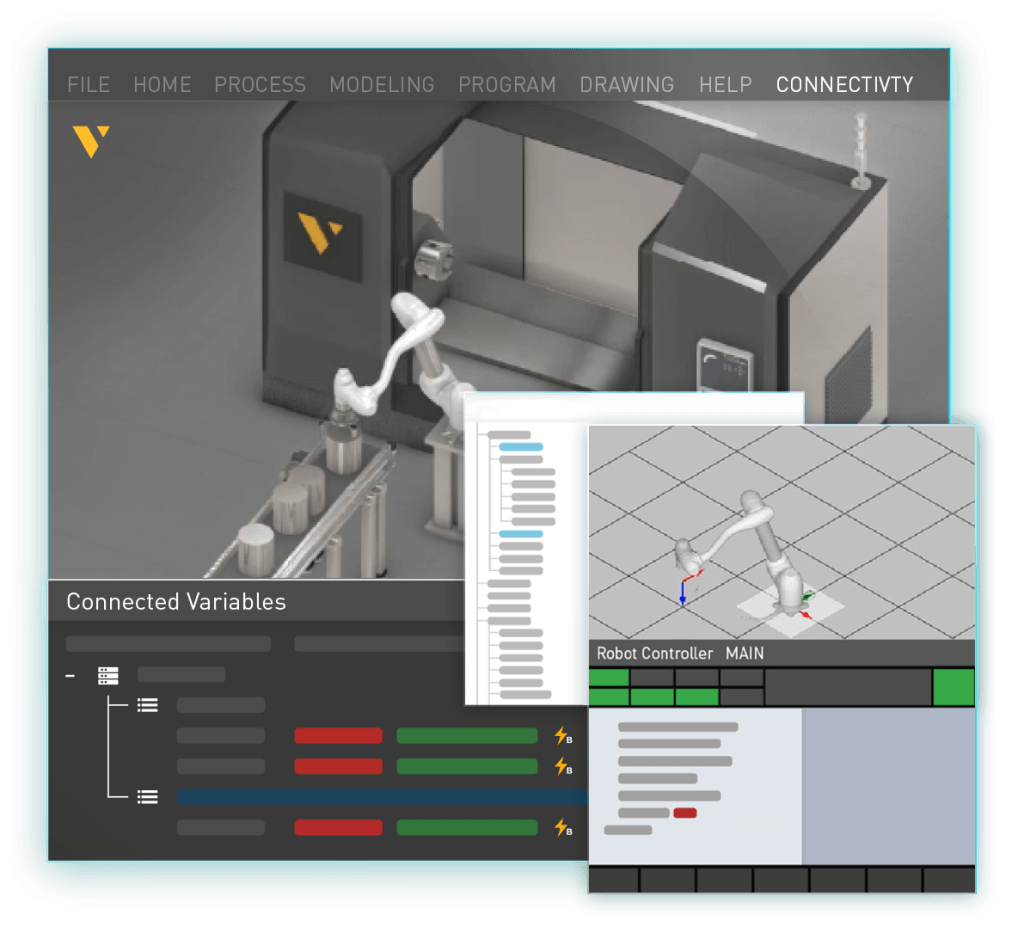

Validate control logic, robot coordination and integration with PLCs and positioners in a virtual environment before physical deployment. This ensures the full production system performs as designed and reduces on-site debugging.

How is Visual Components used in the heavy machinery industry?

MSK Finland advances robot cell automation and intralogistics planning with Visual Components offline programming and manufacturing simulation

MSK Finland increases efficiency in both robot cell automation and intralogistics planning using Visual Components robot offline programming (OLP) and manufacturing simulation software. By creating and validating robot programs virtually,…

Sandvik boosts welding automation and reduces robot programming time with Visual Components OLP

Sandvik Mining manufactures heavy-duty underground loaders and trucks with complex, multi-pass welds. By adopting Visual Components offline programming software, Sandvik reduced robot programming time by more than half, improved weld…

Ponsse drives efficiency in forest machine production with Visual Components OLP

Ponsse, a global leader in forest machine manufacturing, uses Visual Components robot offline programming (OLP) software to improve welding productivity, reduce robot programming time from 10 days to 1, and…

How our customers in heavy machinery benefit

Boost your efficiency by up to 30%

Increase efficiency in your manufacturing operations with our virtual commissioning tools, enabling precise control over process performance through simulation and validation of designs with PLCs and robot controllers.

Save costs by up to 15%

Design many what-if scenarios in hours instead of days, have better insights into your projects, minimize your investment and save additional costs from your projects.

3500+ ready-made CAD components

Use our extensive library of 3D models with more than 1,600 robots, 70+ brands and a wide range of conveyors, machines, resources, robot tools, factory facilities and more.

Reduce robot programming time by up to 80%

Program your robots more quickly and efficiently than with traditional manual programming methods. Test and optimize your programs before downloading them to the physical robots.

Maximize robot utilization by up to 95%

Optimize your robots’ utilization with fast and easy offline programming for tasks such as welding, material processing or spray painting and eliminate robot downtime.

Enhance safety

Reduce the risks of accidents and injuries by programming heavy-duty industrial robots through offline programming software. Program from anywhere without any risk of robot collisions or physical accidents.

Integration with existing engineering and production systems

Visual Components manufacturing simulation and robot offline programming software integrate with common CAD formats and support major industrial robot brands. This makes it easier to connect engineering data with robot programming and adapt programs as designs change.

Supported CAD files for 3D simulation

Here we have a list of supported CAD file types for use with our software. If you have any specific questions about the compatibility of your files, please don’t hesitate to contact us.

All major robot brands supported

Our offline programming software includes built-in post-processors, compatible with 22 leading global robot brands and over 40 robot controllers.

Visual Components for the heavy machinery industry FAQ

They are used to plan layouts, validate robot behavior and prepare robotic welding programs digitally before deployment, reducing shop-floor programming time and production interruptions.

Yes. Simulation allows teams to detect collisions, reachability issues, cycle time bottlenecks and potential errors in production planning before any physical setup is required.

Yes. By simulating robot motion, part placement and full cell operations, engineers can identify bottlenecks, balance workloads and optimize overall production workflows. Offline programming also helps automatically find the most efficient robot paths, minimize cycle times and reduce unnecessary movement.

Yes. Offline programming allows teams to simulate reach, motion and collisions for large welds that are difficult to reposition physically.

Yes. Programs and welding logic can be reused and adapted across variants, making it well suited for high-mix environments.

It is commonly used by manufacturing engineers and production teams and does not require deep simulation or robot programming expertise. Simulation features allow users to plan and validate workflows without specialized robot knowledge.