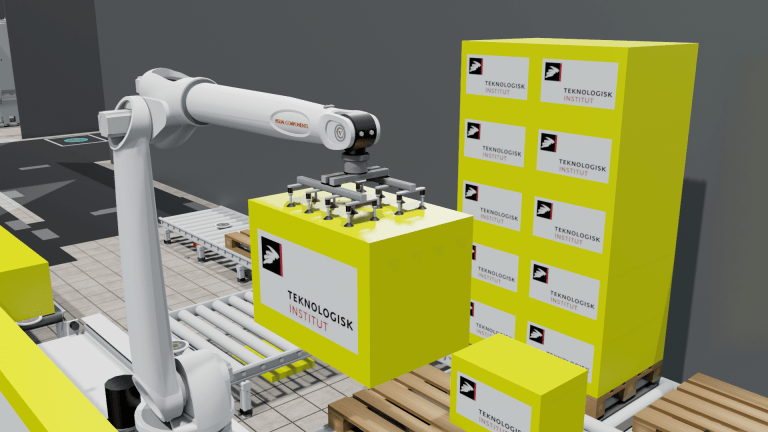

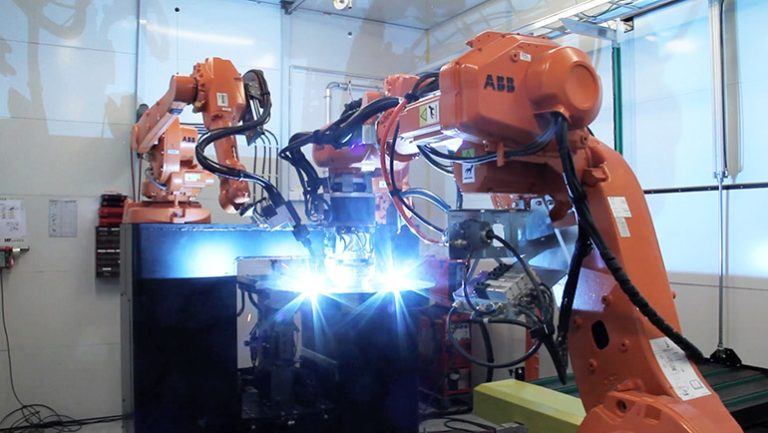

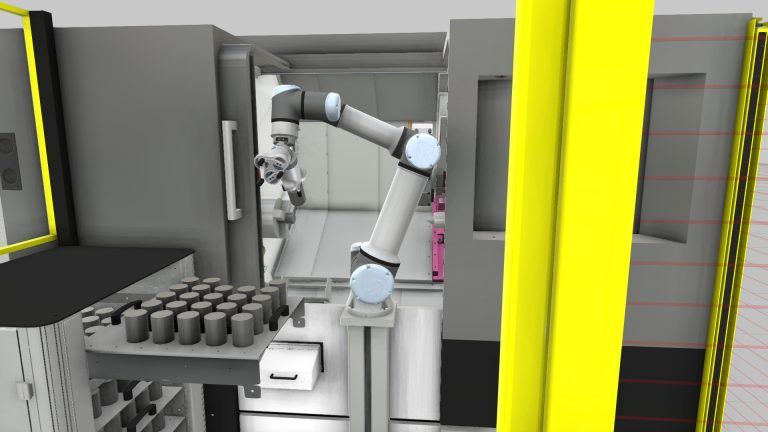

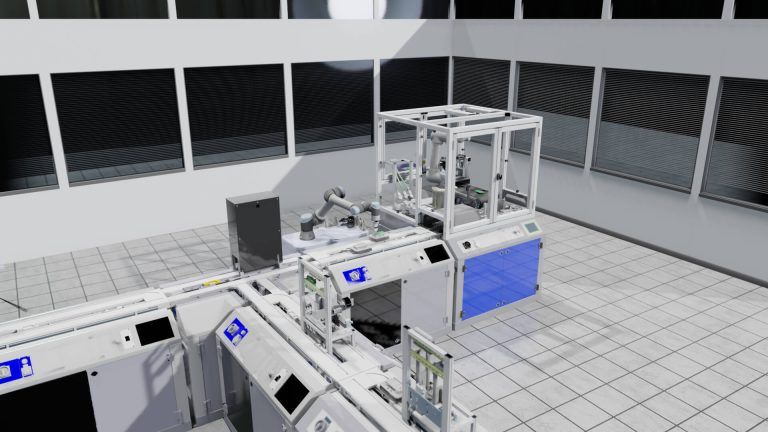

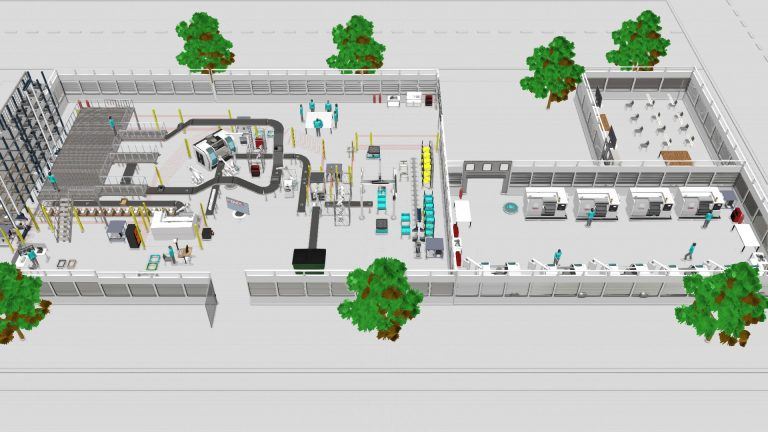

International robotics and simulation competition in China, and smart factory project

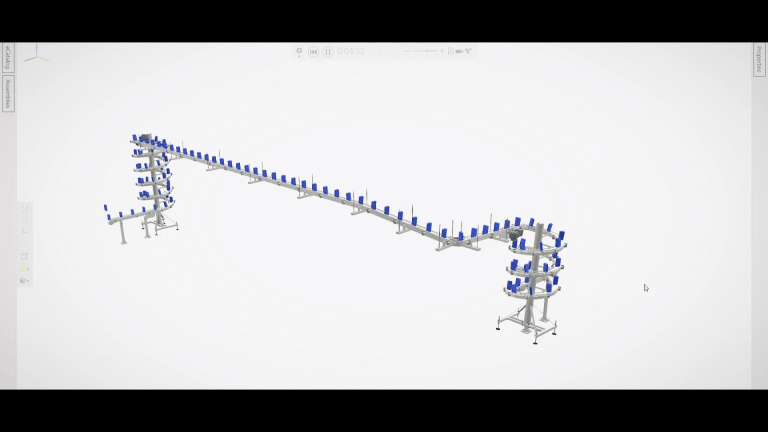

This case is about a large-scale international competition where hundreds of students participated in designing the digital twin of smart factories using Visual Components-based powerful simulation technology. Read more about...