Sandvik boosts welding automation and reduces robot programming time with Visual Components OLP

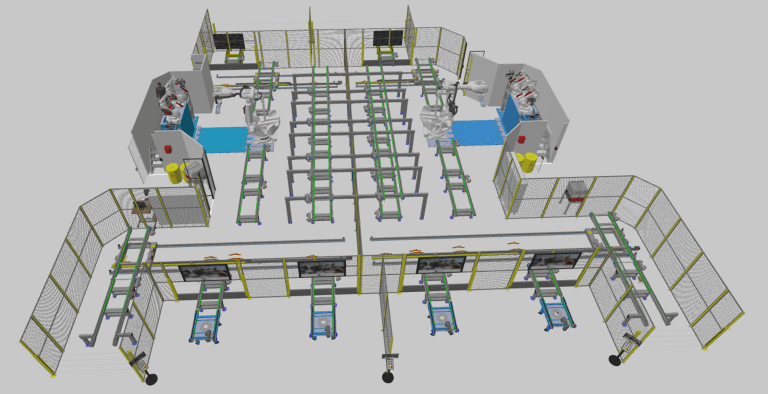

Sandvik Mining manufactures heavy-duty underground loaders and trucks with complex, multi-pass welds. By adopting Visual Components offline programming software, Sandvik reduced robot programming time by more than half, improved weld quality and repeatability and increased robot cell utilization. Simulating and validating weld reachability before production has helped Sandvik accelerate automation, minimize downtime and standardize multi-pass welding across assemblies.

Building heavy-duty underground equipment

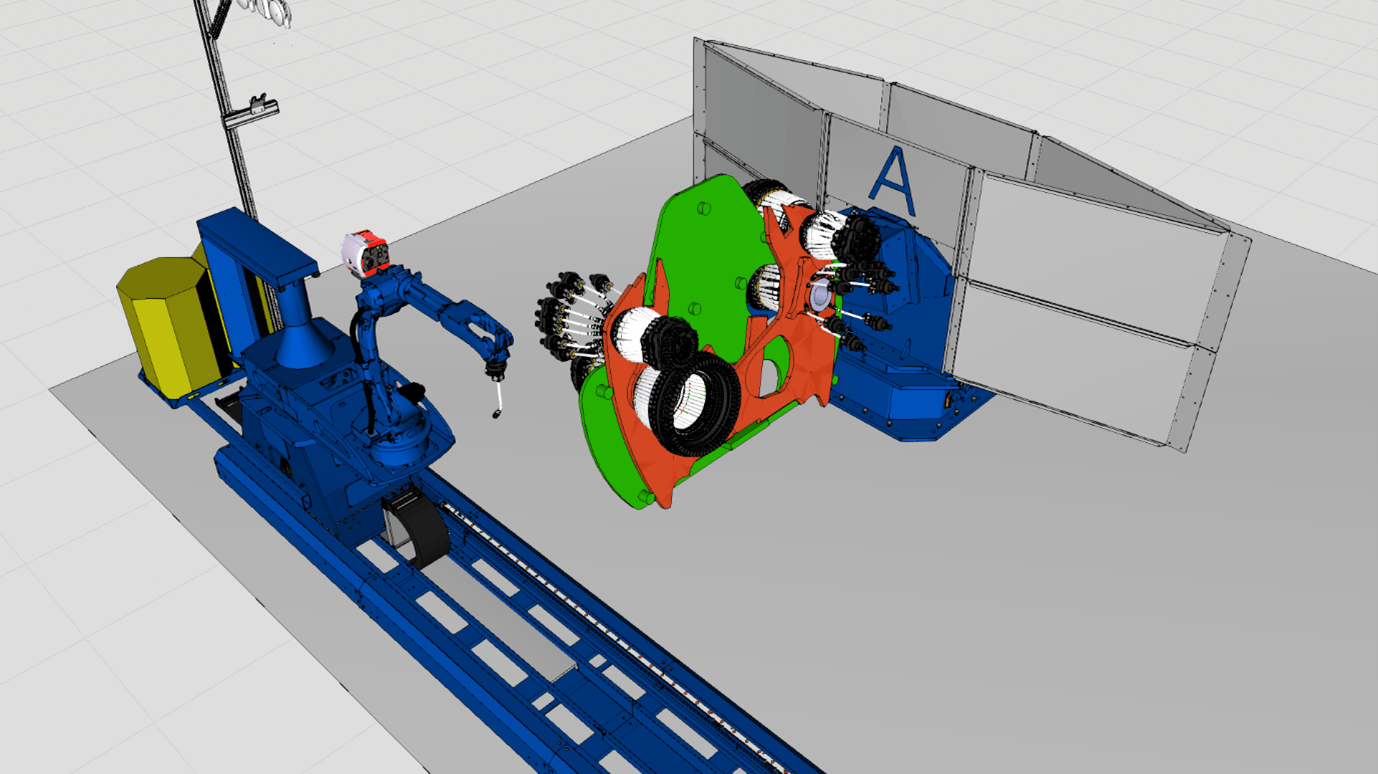

The Sandvik Turku plant is part of Sandvik Mining Load and Haul division, manufacturing underground loaders and trucks since the early 1980s. With around 900 employees, the 60,000 sq. m. (645,834 sq. ft.) facility produces all main frame components, such as front and rear frames, lifting arms and buckets, for machines used in demanding underground mining and tunneling projects worldwide.

These loaders operate in narrow tunnels yet handle lifting capacities up to 25 tons, requiring thick plates, complex and hard-to-reach welds and multi-pass welding that are difficult to program and automate. For example, a single front frame can consume over 100 kilograms of welding wire and most welds are multi-pass, meaning each frame has several hundred welding beads that need to be programmed accurately. Sandvik also aims to weld in PA position whenever possible, which can be challenging when the bevels are not perfectly straight.

The need to speed up complex welding automation

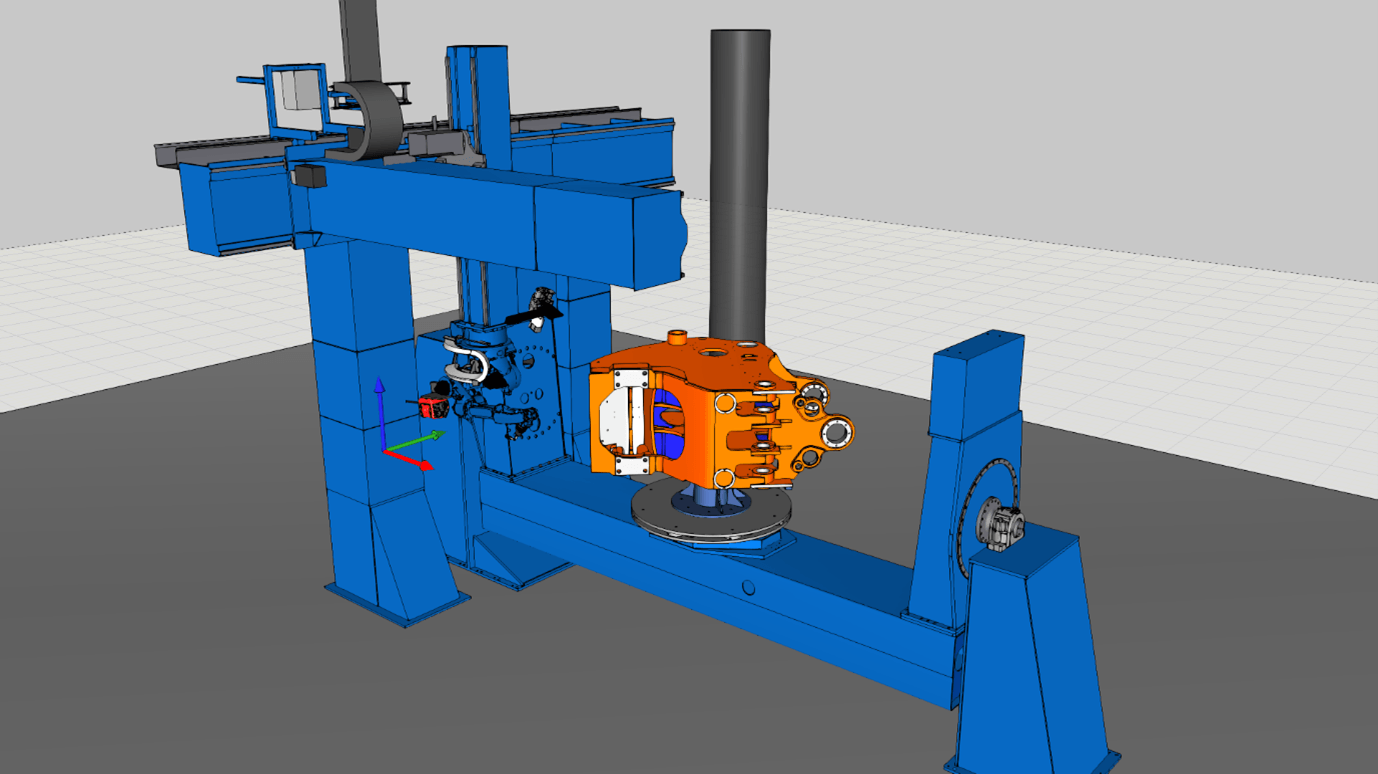

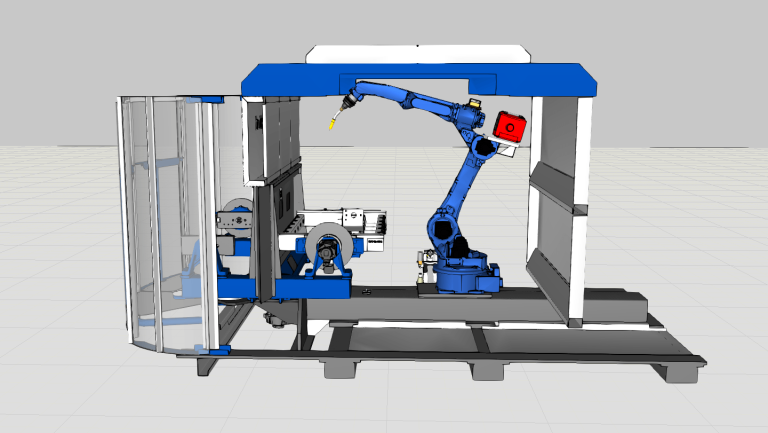

Sandvik has relied on robot welding since the 1990s and has more than doubled its robot welding capacity in recent years. The Turku plant currently operates IGM and Yaskawa welding robots, most with ten or more axes and equipped with MAG welding systems. The largest positioner can handle parts weighing up to 7.5 tons, enabling the team to weld even the heaviest assemblies.

As production volumes and assembly complexity grew, programming robots using a teach pendant was slow and inefficient.

Programming a whole front frame using a teach pendant takes a long time time and we lose production time over that process.

Markus Juntunen, Production Development Engineer, Sandvik

Because the welds are complex, programmers had to try multiple robot positions manually without knowing if the weld was reachable, leading to unnecessary downtime. The manual approach also made it difficult to plan optimal welding sequences and control heat input to prevent deformation.

Sandvik wanted to increase its automation level, reduce robot cell downtime and improve repeatability and weld quality. The team also sought a way to test reachability earlier in the process, so design and manufacturing decisions could be made with better visibility.

How offline programming transformed robot welding

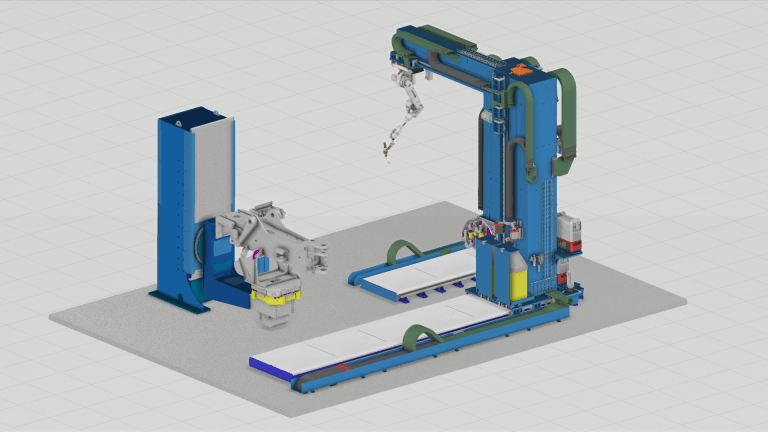

To overcome these challenges, Sandvik Turku adopted Visual Components robot offline programming (OLP) software to program its welding robots virtually. With robot offline programming, the team can now prepare, simulate and validate robot paths before entering the production cell.

With offline programming, we can test the reachability of each weld beforehand and we will not lose production time for nothing.

Markus Juntunen, Production Development Engineer, Sandvik

By simulating the process in Visual Components, programmers can plan welding sequences, define manufacturing order and optimize heat input to minimize deformation.

For the most complex assemblies, such as front frames, the difference has been substantial. For smaller parts, the offline programming phase takes only a few days and the final touch-up in the robot cell can be done in a single work shift, compared to several days or even weeks with teach pendant programming.

A key advantage of Visual Components OLP is the ability to standardize and reuse multi-pass welding profiles.

It is much easier to standardize welding torch position parameters because we can create multi-pass profiles and copy-paste them to the correct bevel or special form like a curve or plate corner. This way, it is possible to achieve constant and repeatable quality in our multi-pass welds and we can do that fast.

Markus Juntunen, Production Development Engineer, Sandvik

Beyond robot programming, the team also uses Visual Components to plan jigs and fixtures before production. By creating a point cloud of torch paths and determining the best frame assembly position relative to the welding positioner, they can give highly accurate boundary conditions to the jig designers. This approach helped them achieve a jig that ensures full reachability and ideal welding positions for every weld.

Faster ramp-up and more efficient robot utilization

The introduction of Visual Components OLP software has transformed robot programming at Sandvik Turku. Programming for large frames can now be prepared offline, with ramp-up completed in just a few weeks. For smaller projects, offline programming is completed in a few days, with final touch-up in the robot cell taking a single shift. Offline programming keeps robot cells productive while programs are prepared, minimizing lost production time and increasing cell utilization.

Weld quality has improved through standardized multi-pass welding templates and the process is more consistent across assemblies.

When we build a new robot cell, we are able to do the ramp-up process much faster with Visual Components.

Markus Juntunen, Production Development Engineer, Sandvik

Looking ahead, Sandvik plans to integrate design-for-manufacturing (DFM) principles more deeply into its design process. By using OLP data to provide early feedback on weldability and reachability, designers can make more automation-friendly design choices, further increasing efficiency and consistency in production.

About Visual Components

Founded by a team of simulation experts and amassing over 20 years in business, Visual Components is one of the pioneers of the 3D manufacturing simulation industry. The organization is a trusted technology partner to a number of leading brands, offering machine builders, system integrators and manufacturers a simple, quick and cost-effective solution to design and simulate production processes and offline robot programming (OLP) technology for fast, accurate and error-free programming of industrial robots.

Want to learn more about the benefits of our solutions for your business? Contact us today!

Further reading

MSK Finland advances robot cell automation and intralogistics planning with Visual Components offline programming and manufacturing simulation

MSK Finland increases efficiency in both robot cell automation and intralogistics planning using Visual Components robot offline programming (OLP) and manufacturing simulation software. By creating and validating robot programs virtually,...

Ponsse drives efficiency in forest machine production with Visual Components OLP

Ponsse, a global leader in forest machine manufacturing, uses Visual Components robot offline programming (OLP) software to improve welding productivity, reduce robot programming time from 10 days to 1, and...

Maximizing efficiency and ROI from day 1: Duun Industrier pre-programs a welding robot cell with Visual Components OLP

Duun Industrier, a leading Norwegian heavy machinery manufacturer, installed the Nordics’ largest robotic welding station in 2013. Utilizing Visual Components for robot programming since 2014, they commissioned a new robot...