Powered by Visual Components: The FlexLink Design Tool

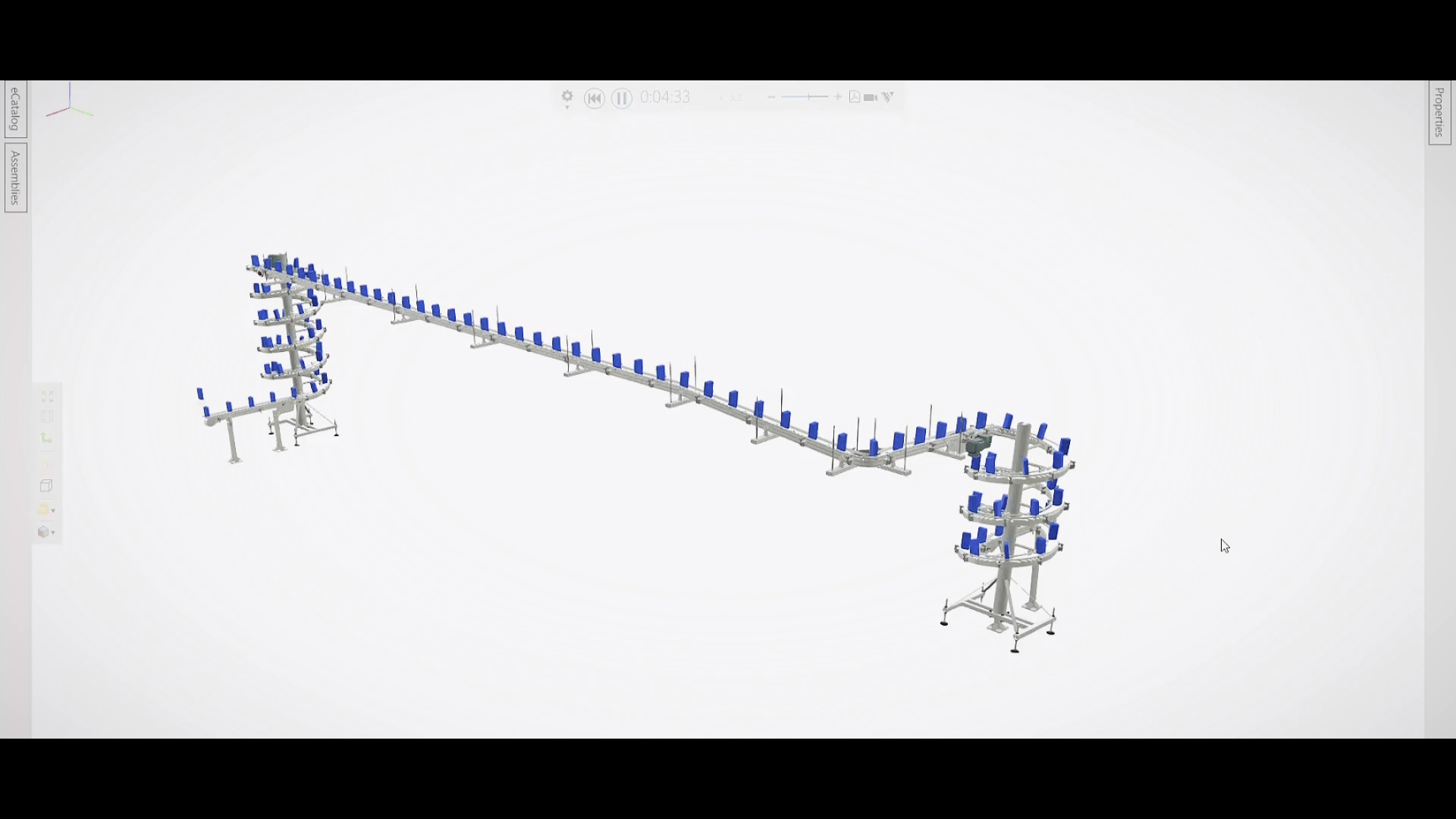

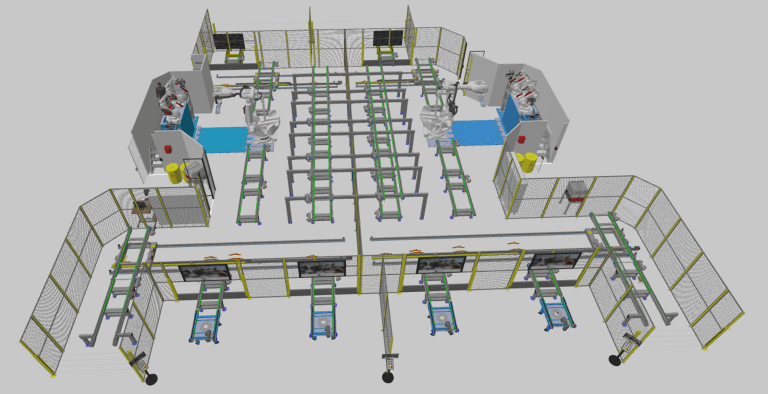

In this second video about the FlexLink – Visual Components partnership, we explore some of the key functionalities of the FlexLink Design Tool that enable it as an effective sales tool of FlexLink systems.

In our first video FlexLink Case Study: Not just a Platform, a Partnership, we learned about FlexLink’s vision for the FlexLink Design Tool, and why they chose the Visual Components 3D manufacturing simulation platform to turn this vision into a reality.

In this second video about the FlexLink/Visual Components partnership, we explore some of the key functionalities of the FlexLink Design Tool that enable it as an effective sales tool of FlexLink systems. We also hear from FlexLink’s COO why hundreds of their customers use the FlexLink Design Tool daily, and how it has positively affected not only their sales but also the customer experience.

Further reading

MSK Finland advances robot cell automation and intralogistics planning with Visual Components offline programming and manufacturing simulation

MSK Finland increases efficiency in both robot cell automation and intralogistics planning using Visual Components robot offline programming (OLP) and manufacturing simulation software. By creating and validating robot programs virtually,...

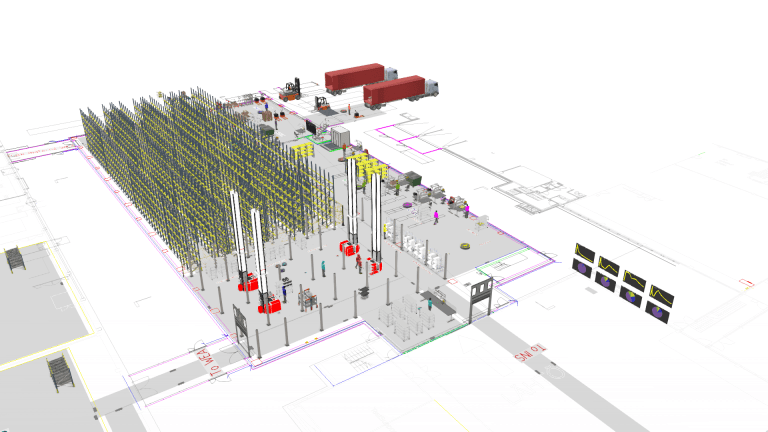

Vaisala optimized and validated its new logistics center with Visual Components

Vaisala recently built a new logistics center at its Vantaa headquarters to support growing production needs. Using Visual Components’ 3D simulation platform, the automation team modeled the entire facility to...

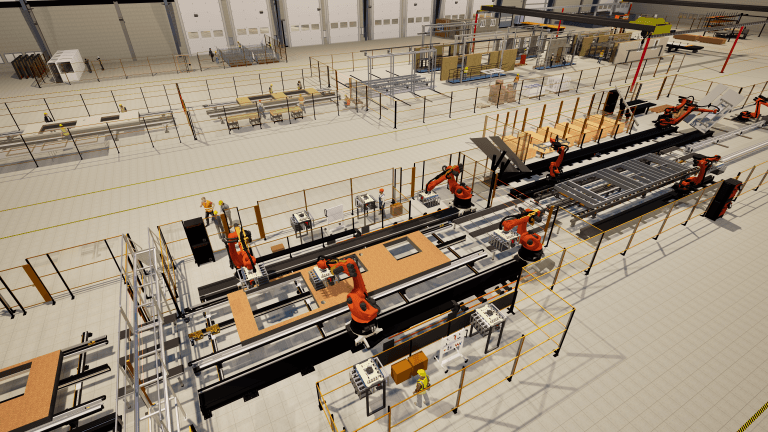

Wiksfors uses Visual Components to bring renovation into the factory era with RenoChain

Modernizing Sweden’s aging housing stock calls for a smarter approach. With Visual Components, Wiksfors developed RenoChain, a factory-based renovation concept that uses simulation to plan and prove a faster, more...