MSK Finland advances robot cell automation and intralogistics planning with Visual Components offline programming and manufacturing simulation

MSK Finland increases efficiency in both robot cell automation and intralogistics planning using Visual Components robot offline programming (OLP) and manufacturing simulation software. By creating and validating robot programs virtually, MSK reduces programming time by half, avoids production downtime and improves program quality, especially in multi-robot cells. The company uses factory simulation to evaluate the suitability of mobile robots for intralogistics, analyzing transfer flows, routes and utilization rates in a digital environment. Together, these tools help MSK maintain a high level of automation in serial production and prepare for future investments.

A high-volume manufacturer leveraging robotics across multiple production processes

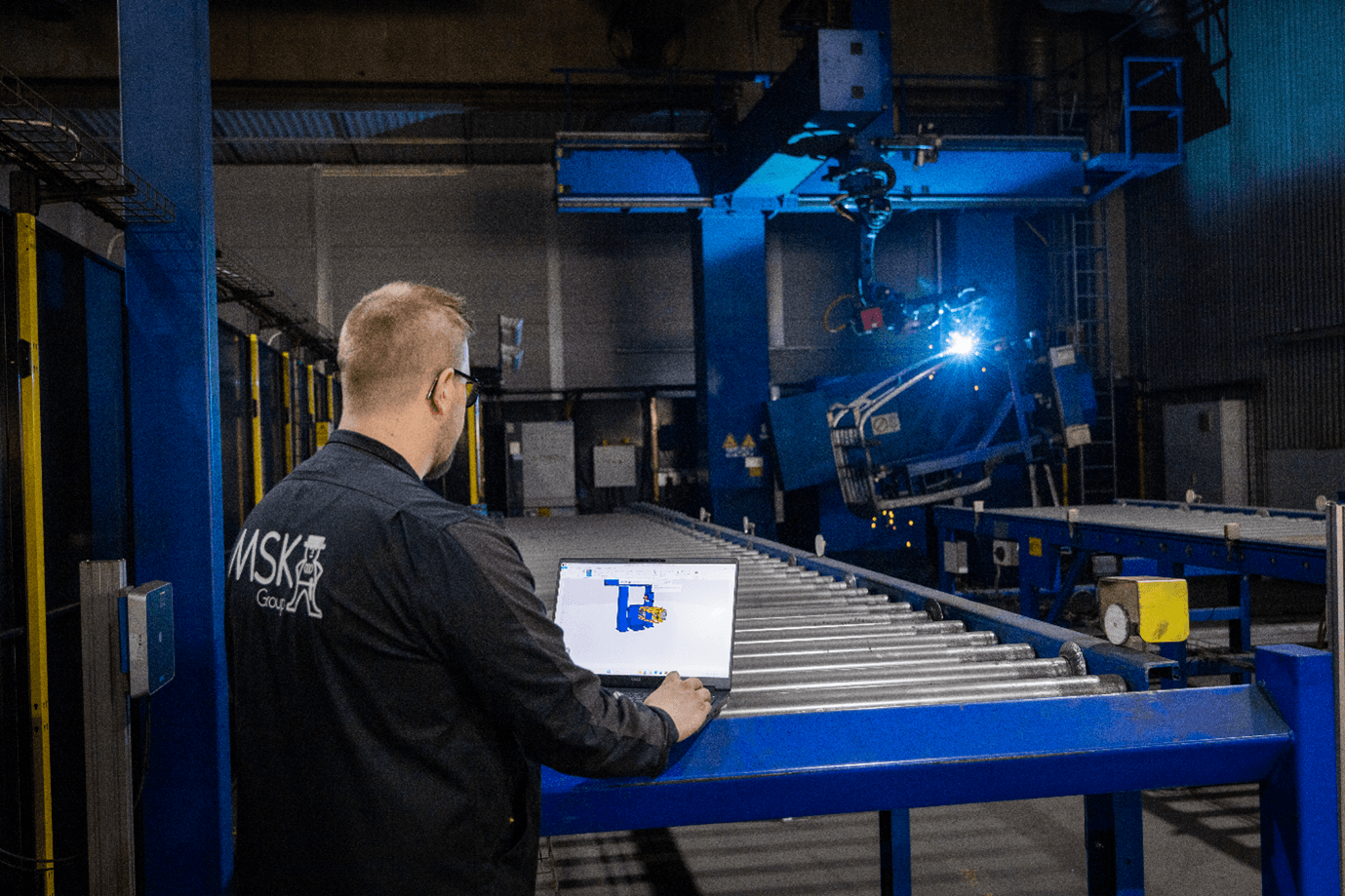

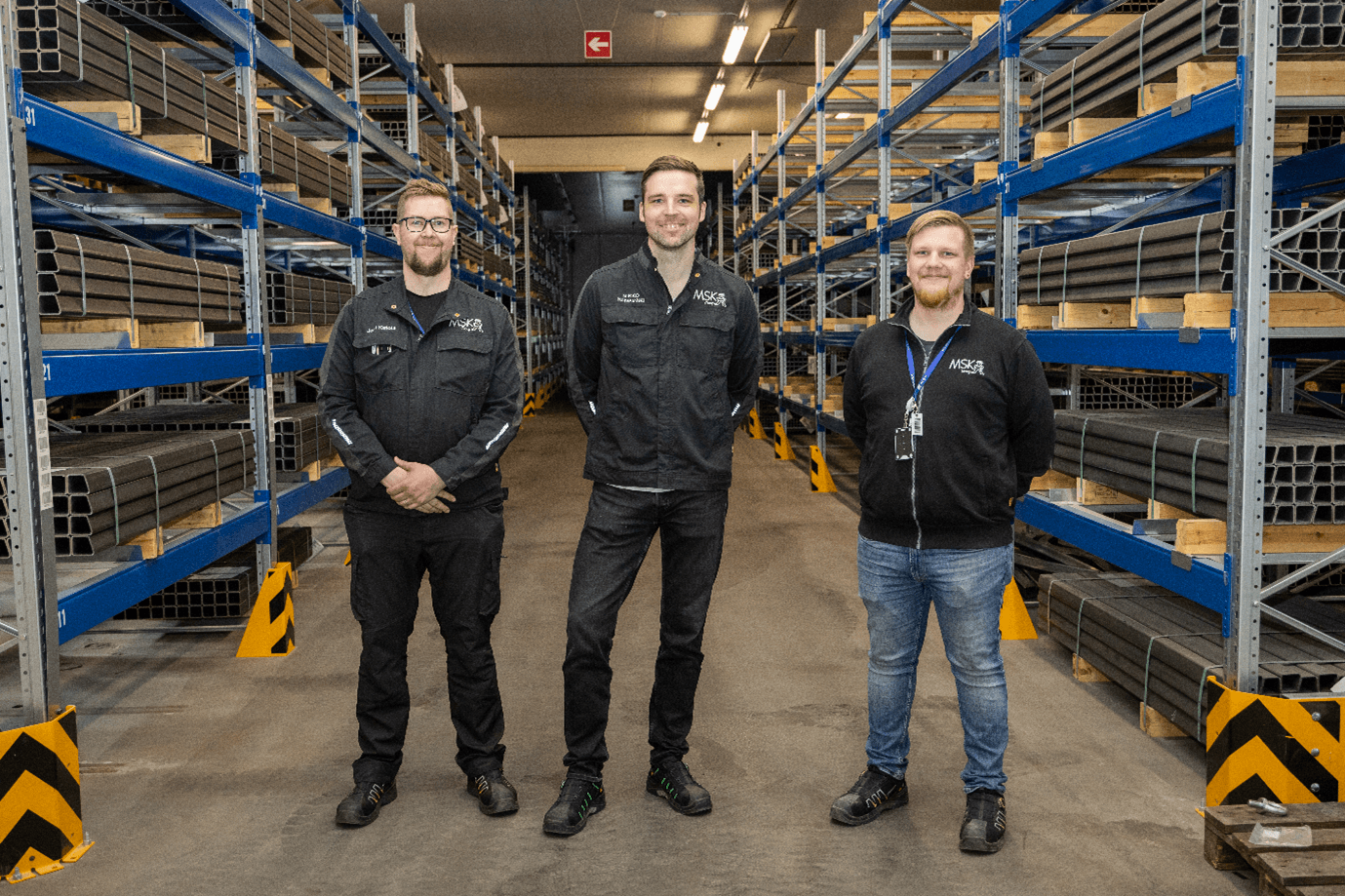

MSK Finland manufactures safety cabins for agricultural and logistics machinery, producing around 14,000 cabins per year in its 60,000 sq. m. (645,834 sq. ft.) facility with around 200 employees. The company manages the entire process from concept design to serial production. Because of the scale and complexity of their products, automation has been essential since the early 1990s, when MSK first adopted industrial robots. Today, the factory uses ABB, Yaskawa and Universal Robots across robotic welding, grinding, painting, tube handling and various material-handling applications. Maintaining a high automation level is a strategic requirement for MSK to remain competitive in high-volume and cost-sensitive markets.

Slow robot programming and labor-intensive logistics limited overall performance

MSK faced two major challenges that impacted productivity. The first was the time and effort required for robot programming using the teach pendant. Programming directly on the robot often meant stopping production, which created delays and tied up resources. The issue became more pronounced in complex setups, particularly in multi-robot ABB MultiMove cells where multiple robots must operate in synchronized motion and conventional teach-pendant programming becomes slow and complex. Commissioning new cells also required significant on-site work and could not begin until the physical equipment was installed.

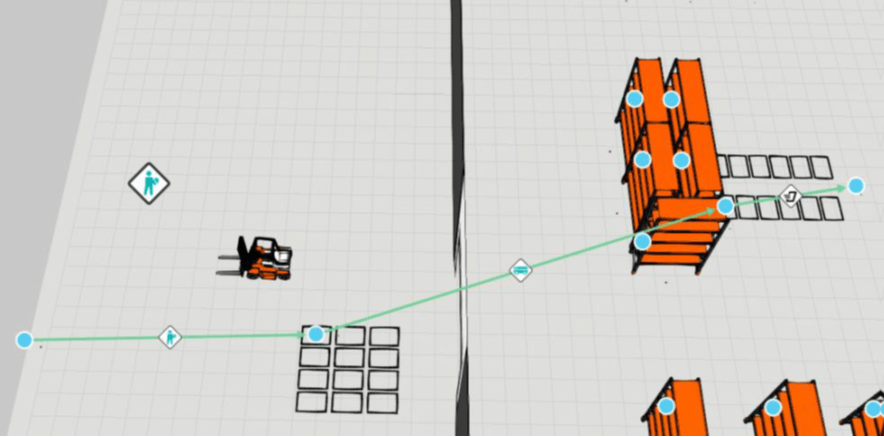

The second challenge was internal logistics. The factory handles thousands of material packages daily, including racks for mudguards, pallets from receiving, painted parts, subassemblies and empty carriers returning to upstream processes. Much of this transportation was done manually with forklifts. As production volumes increased, MSK wanted to understand which transfers could be automated using mobile robots to improve efficiency, such as AGVs or AMRs and whether their existing factory layout and safety constraints would support mobile robot operation. The company needed a data-driven way to evaluate intralogistics automation without interrupting production.

Integrating Visual Components OLP and simulation to design, test and validate automation virtually

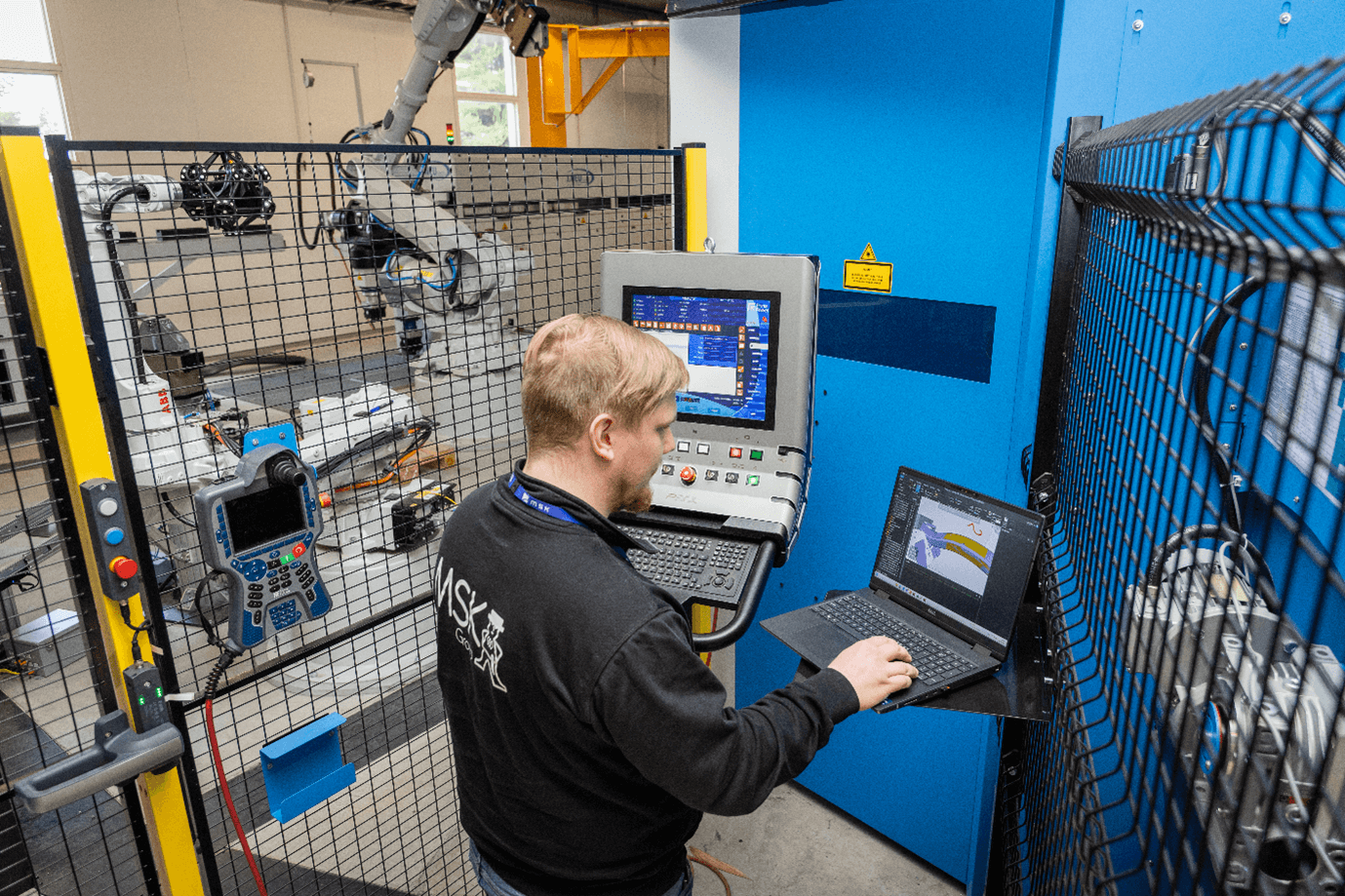

To address these challenges, MSK adopted Visual Components robot offline programming and manufacturing simulation tools. Using Visual Components OLP software, the team creates and validates robot programs on a computer instead of the shop floor. This allows programming work to continue while production runs normally. The virtual environment helps MSK check robot reachability, validate jig and fixture designs, remove unnecessary points in the path and test collision-free movements. Typical programming time has been reduced by around 50% compared to using the teach pendant, depending on the complexity of the robot cell.

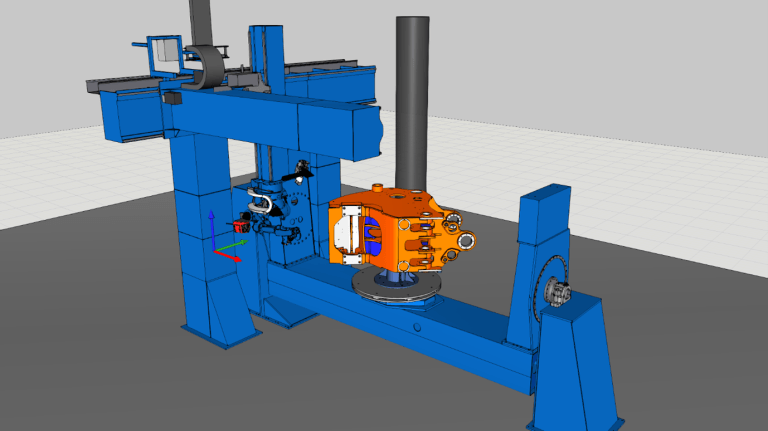

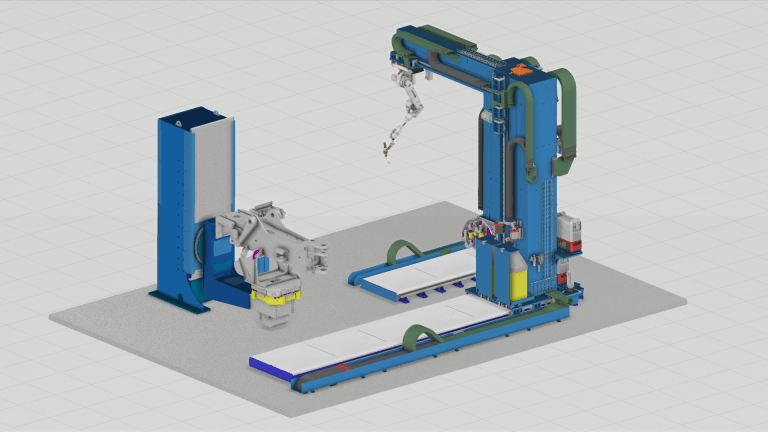

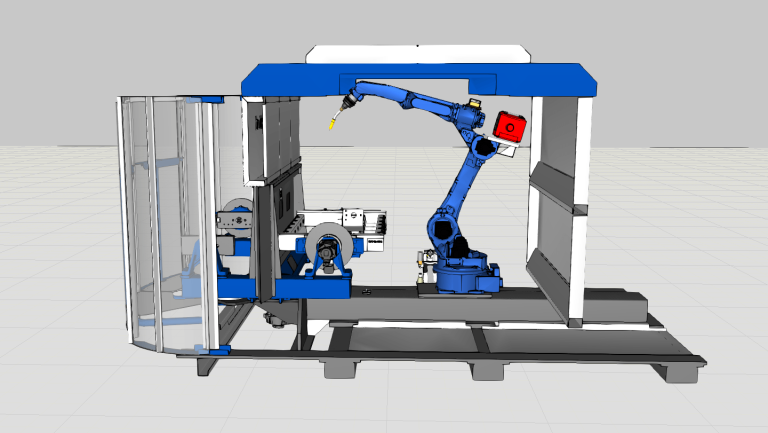

MSK now programs a wide range of robotic systems offline for different industrial processes with Visual Components OLP. Examples include the Yaskawa FMS welding cell equipped with a 3-axis gantry and a 2-axis workpiece positioner, ABB MultiMove welding stations where one robot acts as a jig handler for two welding robots and a grinding cell with two ABB robots operating under separate controllers. Several of these robot cells were fully concepted and programmed offline before the physical cells were assembled, which shortened commissioning time and improved robot program quality.

A multi-robot cell is much more difficult to program than a simple cell. With Visual Components OLP, the typical programming time is one week. It is much more efficient to program with Visual Components because you can check movements and delete unnecessary points.

Joni Ketola, Production Development Engineer, MSK Finland

Visual Components OLP has also made seam search programming more efficient, as the movements can be defined and tested in the simulation environment before being fine-tuned on the real robot. The MSK team is now exploring how to import weld data directly from CAD models to automate even more steps of the programming workflow.

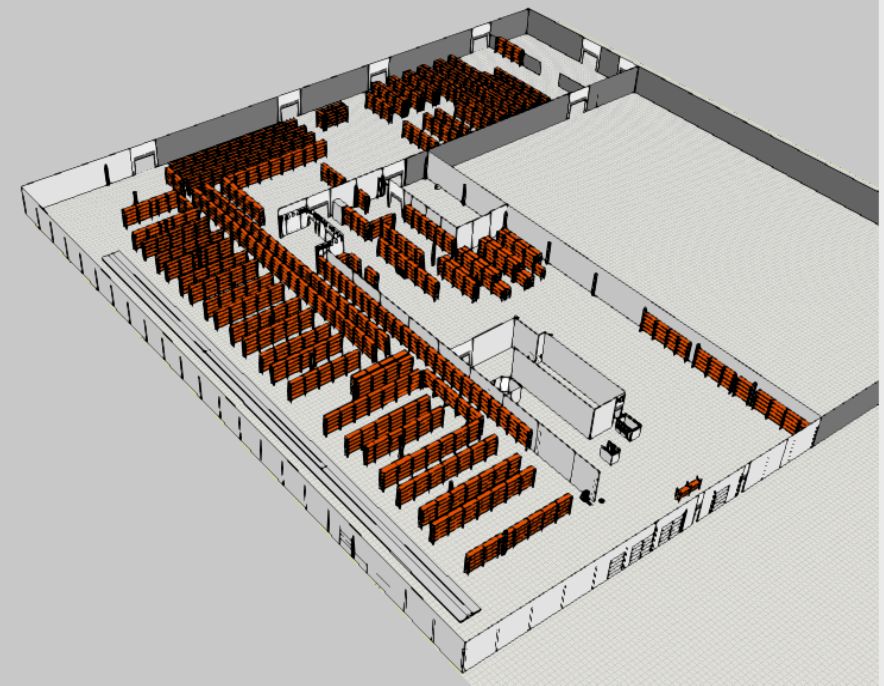

As part of its broader automation strategy, MSK used Visual Components manufacturing simulation to study intralogistics automation. A detailed 3D model of the factory was created based on floor plans, production data and real material flows. The simulation included the movement of mudguard racks, painted parts, empty pallets, subassemblies and palletized materials coming from receiving.

Visual Components has a ready-made product catalog that contains components that are well suited for modeling factory layouts. It also allows you to examine the statics of different components in great detail.

Joni Ketola, Production Development Engineer, MSK Finland

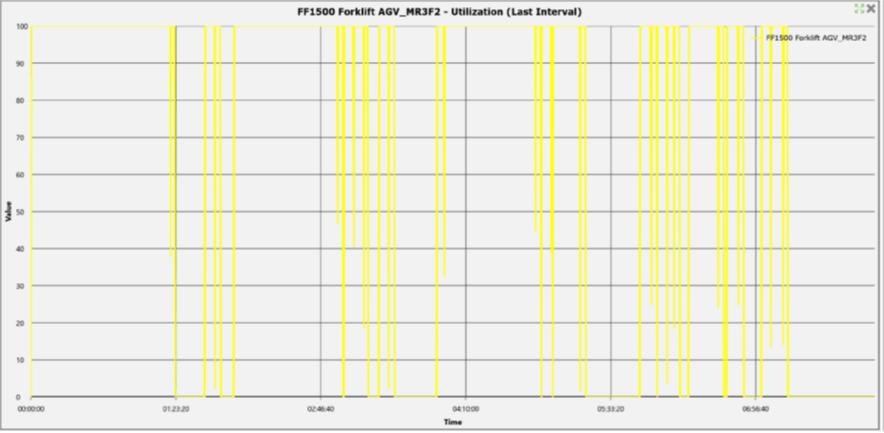

Each transfer task was modeled with realistic frequencies, routes and timing and the AGV behavior was simulated using typical manufacturer data, such as an average driving speed of 1.5 m/s. Simulation helped determine safe driving paths, buffer areas and interactions with human-operated forklifts.

The results showed that a stacker-type AGV could achieve a 68% utilization rate over an eight-hour shift while handling the studied tasks, confirming that mobile robots can be used effectively in MSK’s existing factory layout.

Faster commissioning, improved program quality and a data-driven approach to logistics automation

The integration of Visual Components software into MSK’s workflow has created clear benefits across production. For robot programming, OLP has enabled faster and more consistent robot program development, significantly reducing the time spent on the shop floor. Because robot programs are created and tested virtually, production no longer needs to pause for programming work. Robot paths are more efficient, unnecessary movements are eliminated and collision risks can be resolved early in the virtual model. Being able to prepare programs before a new cell arrives has shortened commissioning time and improved first-time success rates.

The benefit of using Visual Components is we can program robots in the office while robots are working in production. According to my experience, it’s 50% faster to program with Visual Components OLP than the teach pendant. For new robot cells, we can make programs ready even before the actual robot cell is ready.

Joni Ketola, Production Development Engineer, MSK Finland

For intralogistics, manufacturing simulation provided MSK with a reliable way to evaluate how mobile robots would perform without disrupting production. The company now has a clear understanding of which material transfers are most suitable for automation and how AGVs or AMRs could be integrated into their processes. The digital model also gives MSK a platform for testing future scenarios, such as expanding mobile robot fleets, adjusting layouts or integrating robots with ERP and MES systems. This supports the company’s broader strategy of increasing automation not only in robot cells but across the entire production flow.

A scalable digital foundation for future automation investments

By combining robot offline programming with factory simulation, MSK has built a scalable digital foundation that supports both current production needs and future automation initiatives. The company is now better equipped to deploy new robot cells, evaluate intralogistics automation and continuously improve its processes. As MSK explores CAD-driven weld data, more advanced mobile robot applications and additional automated manufacturing steps, Visual Components will continue to support its long-term goal of maintaining a competitive, highly automated production environment.

About Visual Components

Founded by a team of simulation experts and amassing over 20 years in business, Visual Components is one of the pioneers of the 3D manufacturing simulation industry. The organization is a trusted technology partner to a number of leading brands, offering machine builders, system integrators and manufacturers a simple, quick and cost-effective solution to design and simulate production processes and offline robot programming (OLP) technology for fast, accurate and error-free programming of industrial robots.

Want to learn more about the benefits of our solutions for your business? Contact us today!

Further reading

Sandvik boosts welding automation and reduces robot programming time with Visual Components OLP

Sandvik Mining manufactures heavy-duty underground loaders and trucks with complex, multi-pass welds. By adopting Visual Components offline programming software, Sandvik reduced robot programming time by more than half, improved weld...

Ponsse drives efficiency in forest machine production with Visual Components OLP

Ponsse, a global leader in forest machine manufacturing, uses Visual Components robot offline programming (OLP) software to improve welding productivity, reduce robot programming time from 10 days to 1, and...

Maximizing efficiency and ROI from day 1: Duun Industrier pre-programs a welding robot cell with Visual Components OLP

Duun Industrier, a leading Norwegian heavy machinery manufacturer, installed the Nordics’ largest robotic welding station in 2013. Utilizing Visual Components for robot programming since 2014, they commissioned a new robot...