FlexLink Case Study: Not just a Platform, a Partnership

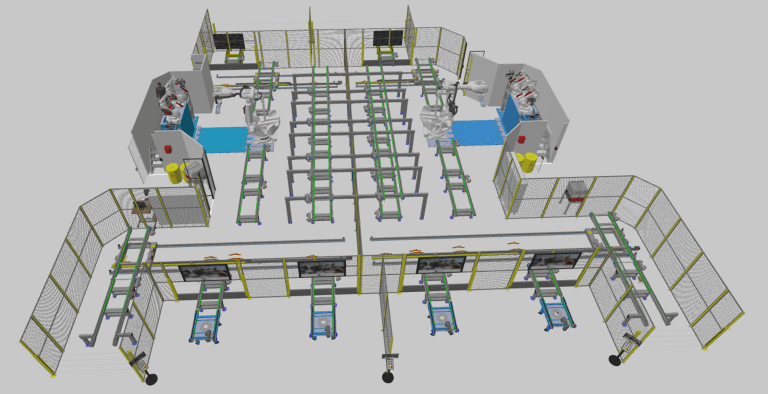

In this case study, we explore how FlexLink, a Sweden-based manufacturer of flexible, modular conveyors and industrial automation equipment, partnered with Visual Components to turn their vision for a 3D design and visualization tool into a reality.

Flexlink is a Gothenburg, Sweden, based manufacturer of flexible, modular conveyors and industrial automation equipment. Founded in 1980 and part of the Coesia Group since 2012, FlexLink today has more than 1,100 employees with operating units in 27 countries.

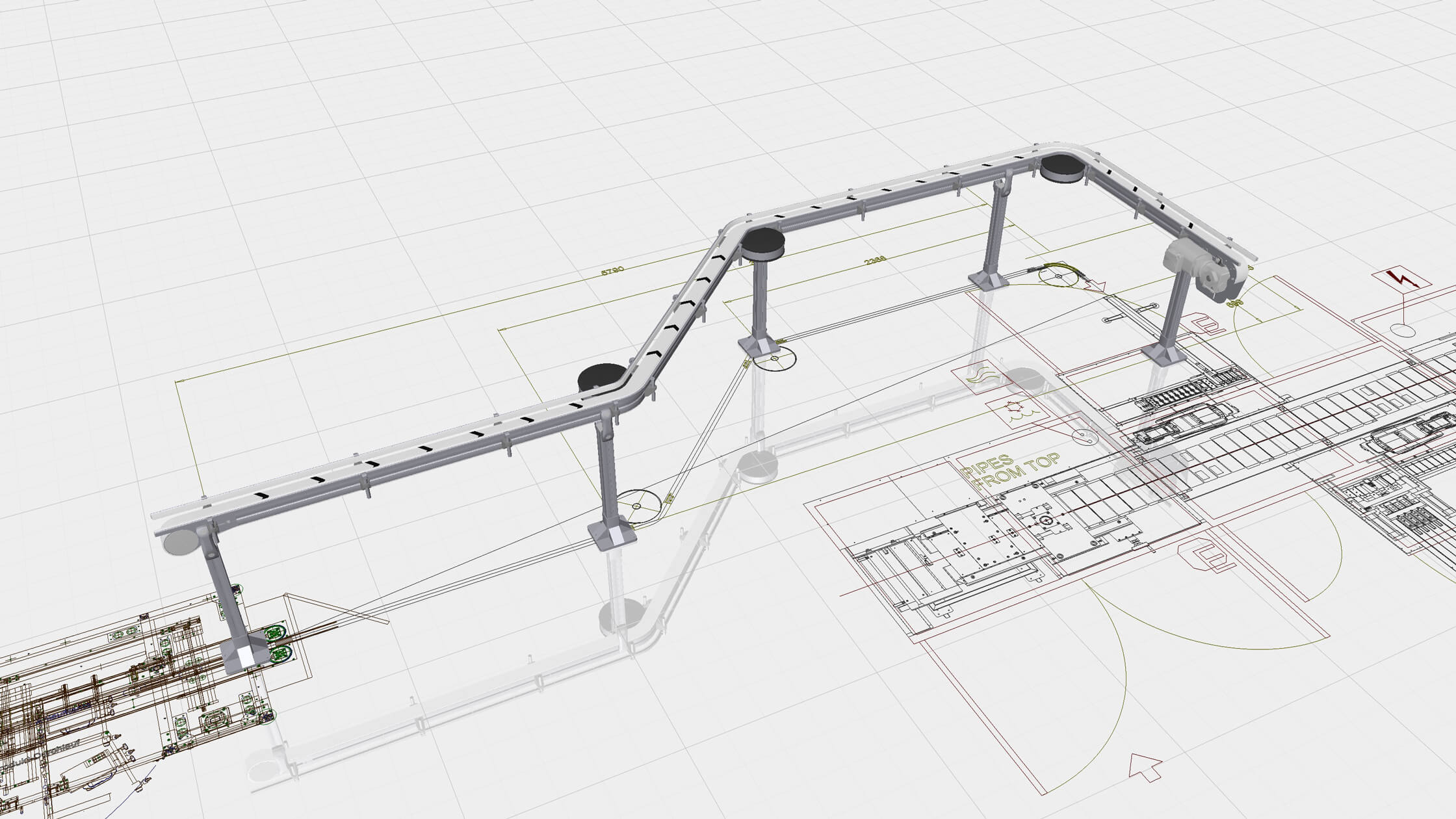

In 2013, FlexLink initiated a search for a partner to support the development of a new visualization tool, which would become the FlexLink Design Tool. Following an extensive evaluation, FlexLink selected Visual Components to utilize their 3D manufacturing simulation platform. In this case study, we explore the history of this partnership, FlexLink’s vision for the FlexLink Design Tool, and how this vision became a reality with Visual Components.

Further reading

MSK Finland advances robot cell automation and intralogistics planning with Visual Components offline programming and manufacturing simulation

MSK Finland increases efficiency in both robot cell automation and intralogistics planning using Visual Components robot offline programming (OLP) and manufacturing simulation software. By creating and validating robot programs virtually,...

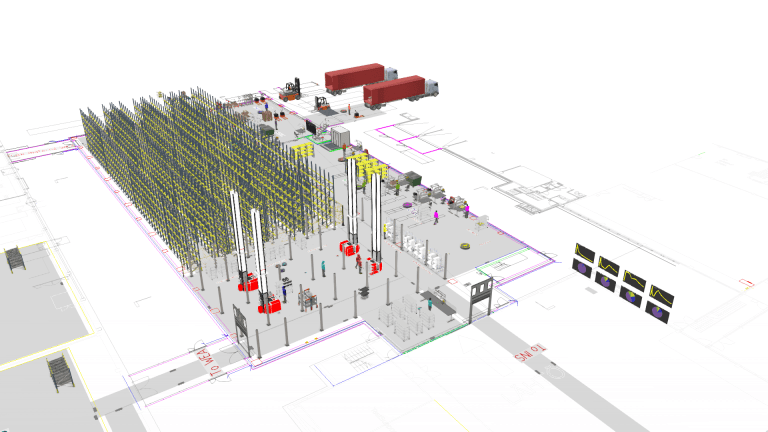

Vaisala optimized and validated its new logistics center with Visual Components

Vaisala recently built a new logistics center at its Vantaa headquarters to support growing production needs. Using Visual Components’ 3D simulation platform, the automation team modeled the entire facility to...

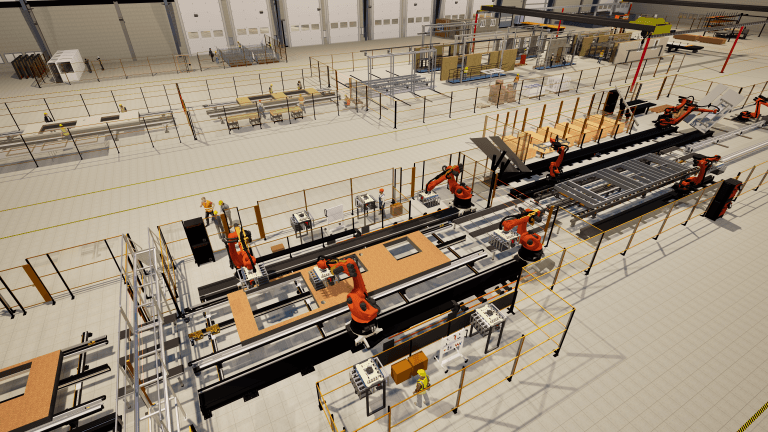

Wiksfors uses Visual Components to bring renovation into the factory era with RenoChain

Modernizing Sweden’s aging housing stock calls for a smarter approach. With Visual Components, Wiksfors developed RenoChain, a factory-based renovation concept that uses simulation to plan and prove a faster, more...