Manufacturing simulation and robot offline programming as the foundation of digital production planning

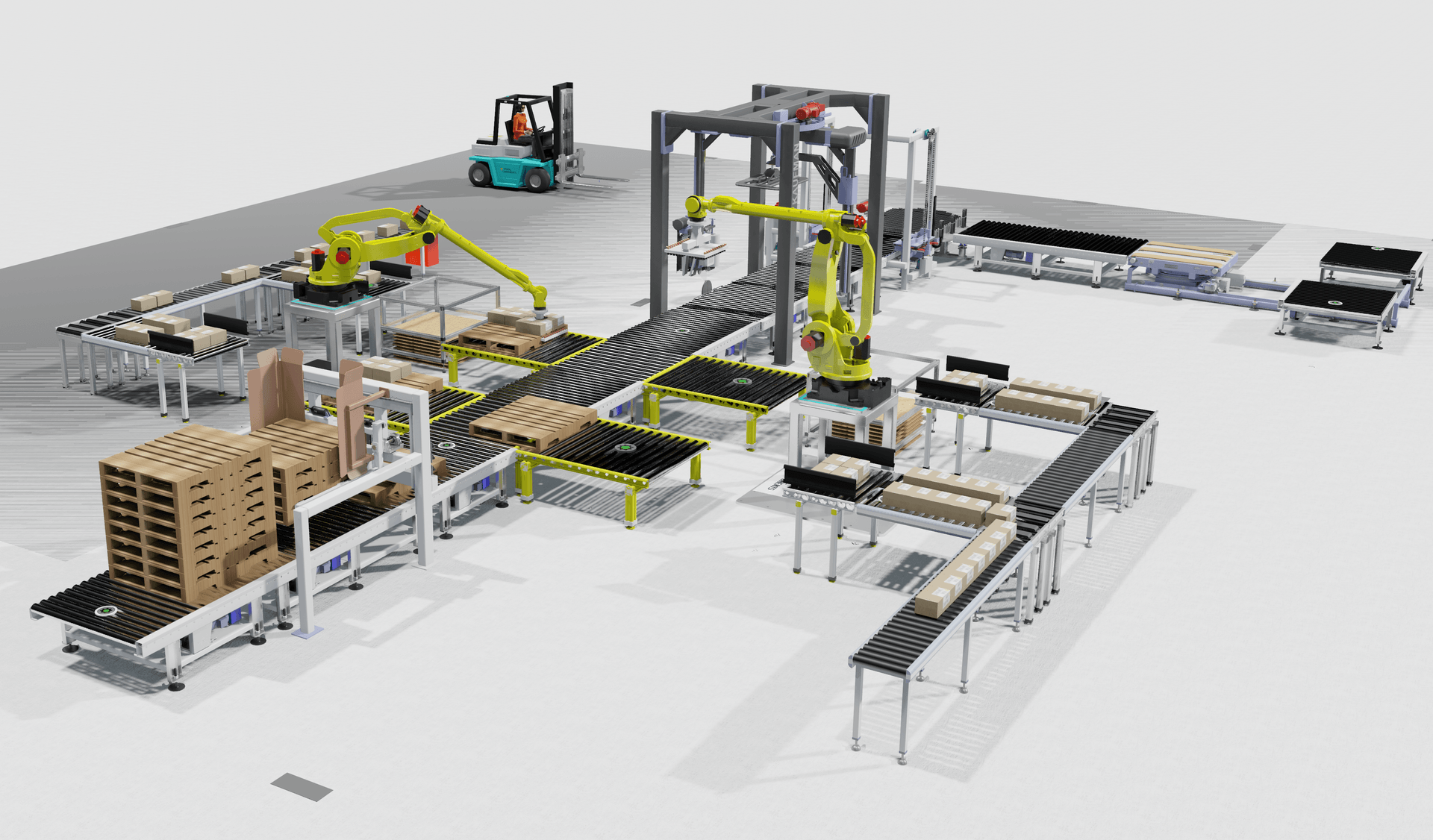

Manufacturing simulation helps companies validate feasibility, optimize performance and reduce risk before building real systems. By combining production simulation with offline robot programming, manufacturers can test cycle times, robot reach, material flow and automation strategies in a virtual environment. This reduces commissioning time, avoids costly mistakes and improves production quality.

Manufacturers are under growing pressure to plan faster, reduce risk and deliver consistent quality before a single robot is installed or a production line is built. As automation complexity increases, one principle is becoming standard practice: simulate before it becomes real.

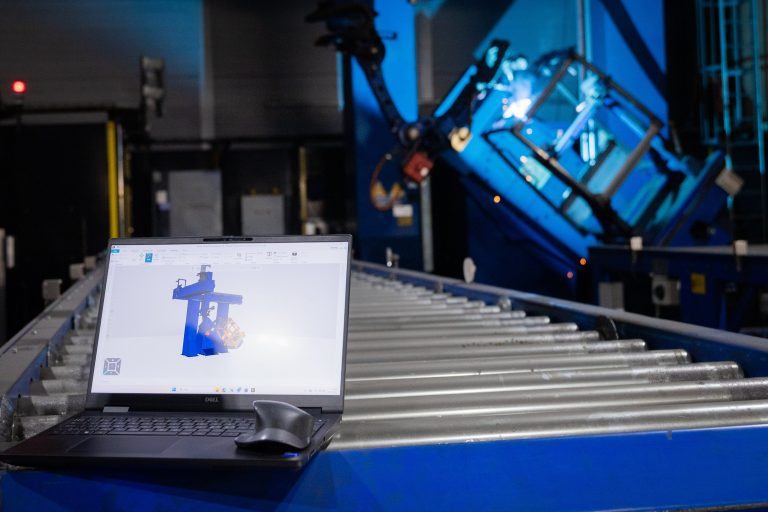

Manufacturing simulation software and robot offline programming allow engineering and production teams to validate systems digitally long before physical implementation. In a recent Konstruktionspraxis podcast, Matthias Wilhelm from Visual Components shared how simulation, offline programming and model-based engineering are shaping the future of digital production planning.

What follows is a practical experience based view of why these technologies are no longer optional and how they are evolving.

Manufacturing simulation software as a decision backbone

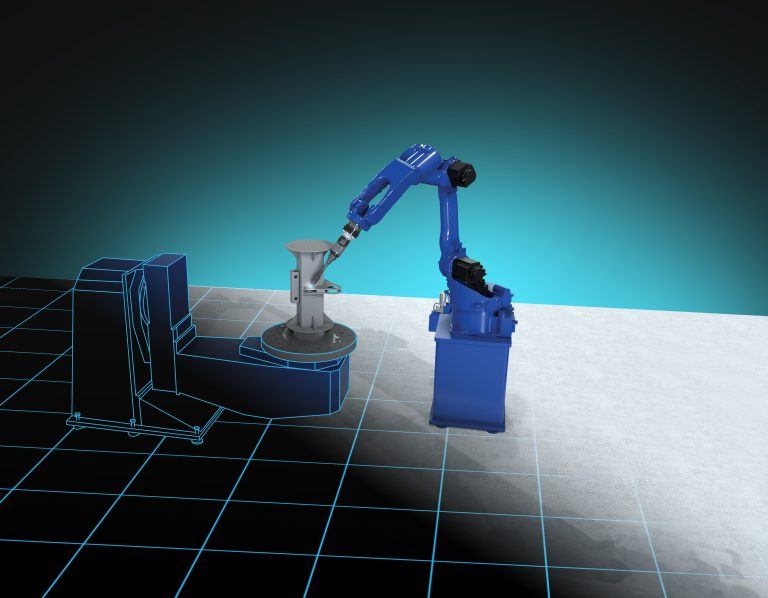

Manufacturing simulation software enables companies to create a digital model of their production system and evaluate it under real world constraints. Instead of relying on assumptions, teams can test how a planned line will actually perform once it is built.

One of the most immediate benefits is feasibility and concept validation. Simulation allows engineers to check whether a robot can reach all required positions, whether the planned cycle time is realistic and whether the expected output can be achieved over a full shift. It also makes it possible to evaluate whether robots, conveyors and transport systems are utilized efficiently rather than becoming bottlenecks or idle assets.

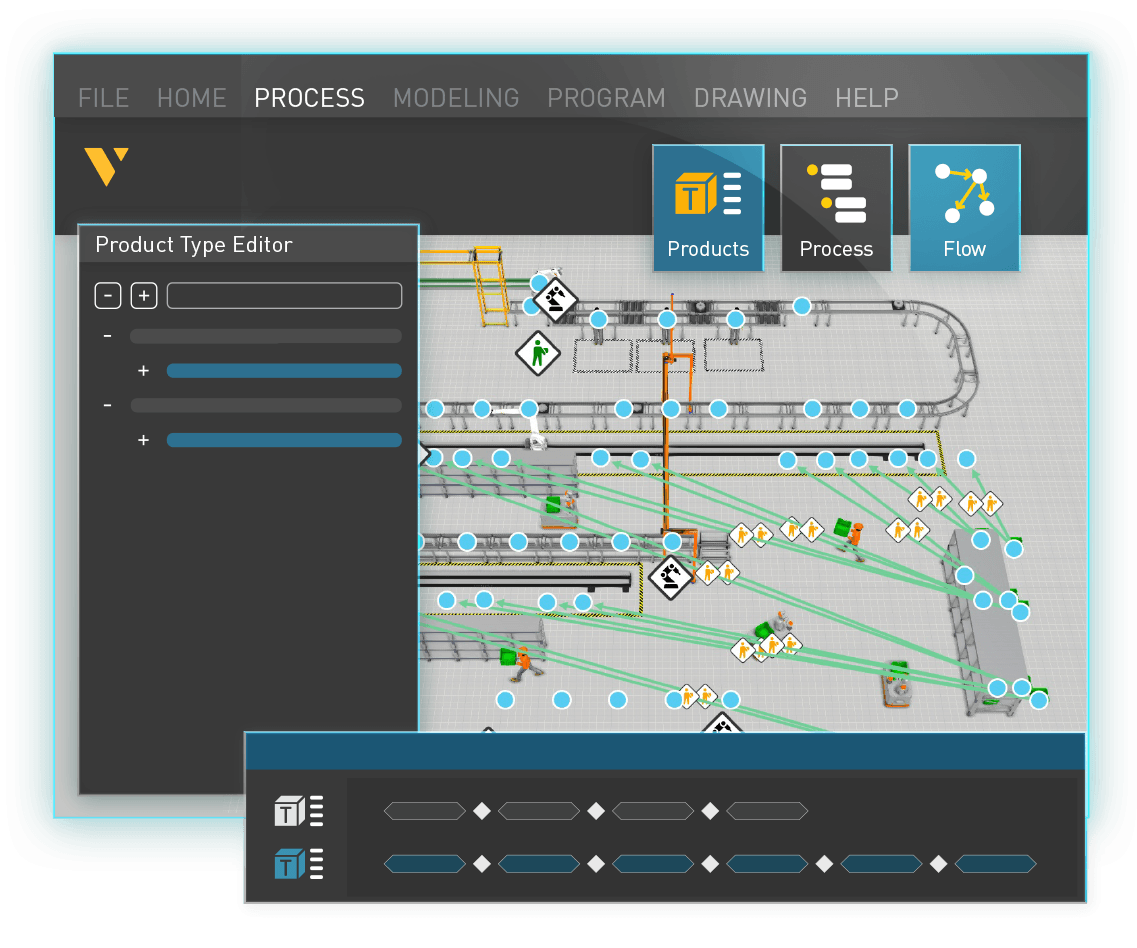

Beyond technical validation, simulation plays a critical role in decision making through visualization. A moving dynamic model of a production line communicates far more clearly than spreadsheets or two dimensional drawings. This is especially important when decisions involve multiple stakeholders. Visual simulation helps align engineering, production and management around a shared understanding of how a system will work in practice.

Simulation also contributes directly to quality improvements. Automation only delivers consistent quality when systems are designed correctly from the start. By validating automation concepts virtually, companies reduce rework, instability and last minute fixes during commissioning and ramp up.

The most common and costly automation mistake

A recurring issue in automation projects is starting with hardware instead of validation. Many companies purchase a robot, install it on the shopfloor and only then discover fundamental problems. These may include limited reach, an incorrectly sized robot, unrealistic cycle times or poor accessibility for safety and maintenance.

Manufacturing simulation software exposes these issues early when changes are still inexpensive and alternative solutions can be explored. Different robot types, layouts and automation strategies can be tested virtually without disrupting production or committing capital prematurely.

How robot offline programming accelerates production

Offline robot programming is a natural extension of manufacturing simulation. In production simulation, robots can already be programmed virtually to validate cycle times and availability for handling tasks such as pick and place, machine loading or palletizing. These programs can then be transferred directly to the real robot.

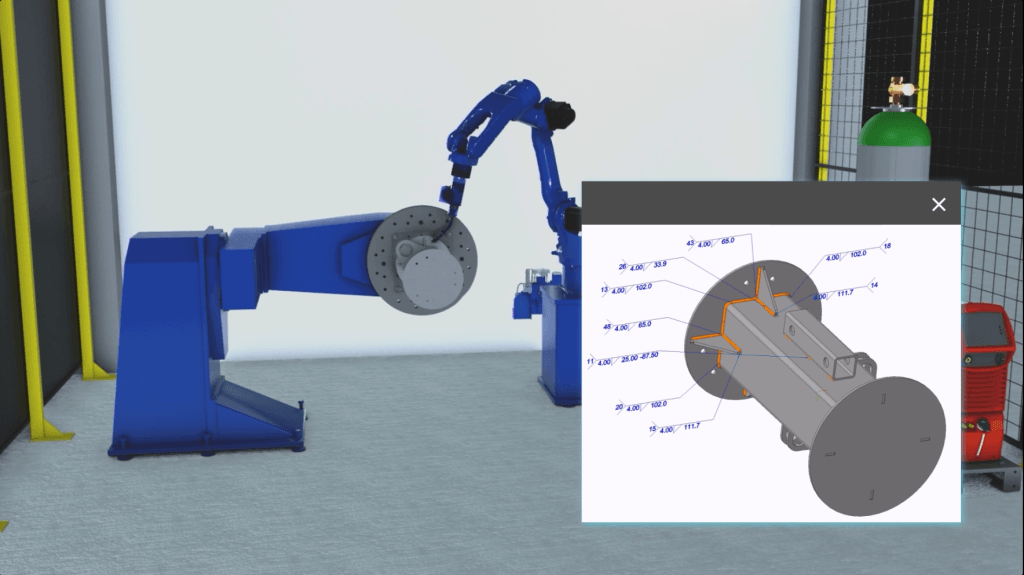

For process applications such as robotic welding, cutting, painting, gluing or sealing, offline programming becomes even more valuable. Engineers can prepare and optimize robot paths while the cell continues to run in production. Process strategies can be tested virtually, quality improves through consistent and repeatable motion and downtime during changeovers is significantly reduced. Instead of stopping a welding cell to teach paths manually, programming becomes a parallel background activity.

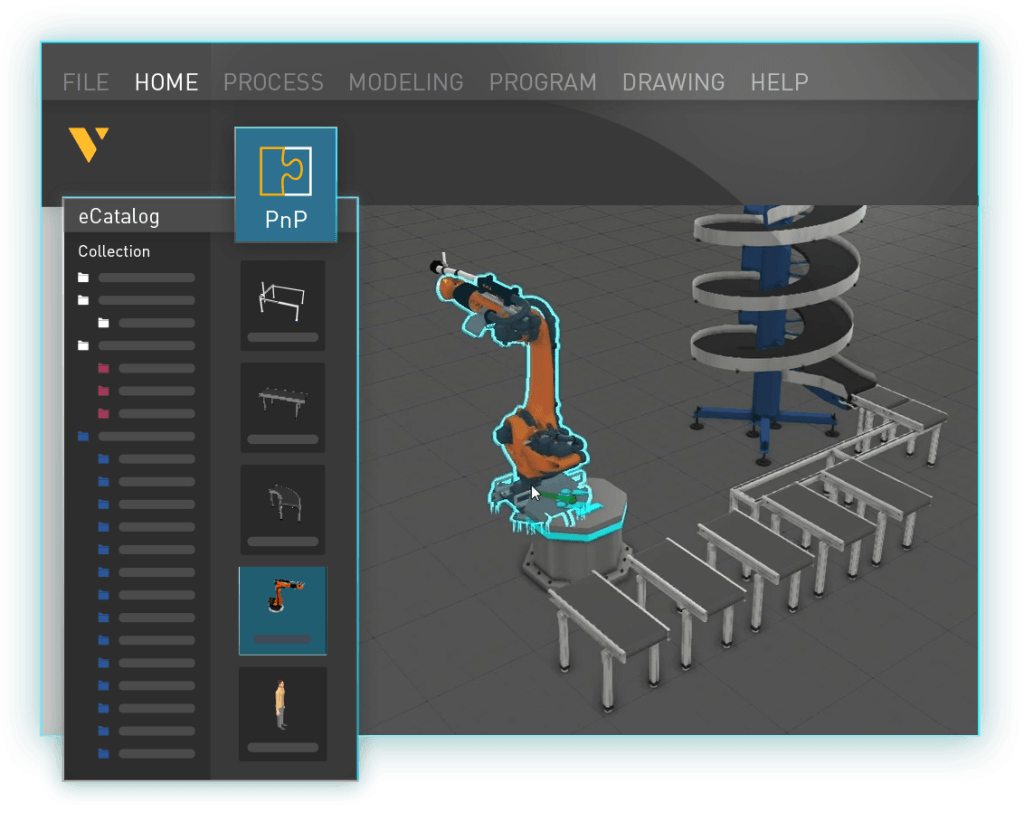

One offline programming software for many robot brands

Modern production environments rarely rely on a single robot manufacturer. Managing multiple vendor specific programming tools increases complexity, training effort and dependency on specialists.

Simulation-based offline robot programming software addresses this by allowing engineers to work with robots from many manufacturers within a single interface. This simplifies workflows, reduces skill silos and lets teams focus on process quality and production goals rather than maintaining expertise in multiple proprietary tools.

Why model-based engineering comes before AI in manufacturing

Artificial intelligence is often presented as the next major leap in manufacturing automation. In practice, AI is only as effective as the data and domain knowledge it is built on.

In processes such as welding, optimizing purely for speed or cycle time can lead to distortion, rework and quality issues. Human expertise such as weld sequencing, heat input management and process order still plays a critical role. Model-based engineering addresses this challenge by using manufacturing information already defined in the CAD model such as weld definitions and process intent to automatically generate robot paths.

This approach embeds engineering knowledge directly into the programming workflow. Rather than replacing expertise, it makes that expertise reusable and scalable while creating a structured foundation for future AI assisted optimization.

Democratizing manufacturing simulation and offline programming across teams

The long term goal of digital production planning is not simulation reserved for specialists but simulation used across departments. When manufacturing simulation software is accessible and easy to use, it can support early concept validation in sales, detailed system planning in engineering, virtual commissioning by specialists and changeover preparation in production.

This democratization mirrors the evolution of CAD tools decades ago and is a key requirement for scaling automation in high-mix low-volume manufacturing environments.

FAQ about manufacturing simulation and offline robot programming

Manufacturing simulation software allows companies to create a digital model of a production system in order to test layouts, robot motion, material flow and key performance indicators such as cycle time and throughput before anything is built physically.

Read more here.

Manufacturing simulation can be used by sales teams, engineers, production planners and automation specialists especially when tools are designed to be intuitive and accessible across departments.

Simulation reveals reach limitations, cycle time issues, layout constraints and utilization problems early in the project when changes are still fast and inexpensive to make.

Offline robot programming is the creation and validation of robot programs in a virtual environment rather than on the shop floor. This allows production to continue while new robot programs are prepared and tested.

Read more here.

Yes. Robot offline programming enables consistent repeatable weld paths and allows engineers to test welding strategies virtually, helping to reduce distortion, rework and manual touch up.

Not yet. AI still lacks sufficient manufacturing specific knowledge in many areas. Model-based engineering currently provides a more reliable way to automate robot path generation while preserving expert process knowledge.

Further reading

Fast and easy robot offline programming (OLP) for welding: a practical no-code workflow

Robot offline programming (OLP) makes robotic welding faster, more predictable and easier to manage, especially in high-mix, low-volume environments. This guide outlines the foundational OLP workflow, covering digital cell setup,...

How offline programming software improves robotic welding efficiency

Offline programming software makes robotic welding more efficient by enabling manufacturers to create and optimize robot programs directly in a digital environment. It supports a wide range of processes including...

Next-level robot offline programming automation with model-based engineering

Explore how model-based engineering enables the next level of robot offline programming automation by connecting design and manufacturing through model-based definition. With validated manufacturing data exported via Capvidia tools to...